A steel spherical crown polymer mortar structure support and its construction method

A technique of polymerizing mortar and polymer, applied in bridge parts, erecting/assembling bridges, bridges, etc., can solve problems such as bias voltage, support void, etc., and achieve simple support structure, reasonable force, and prevent void Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

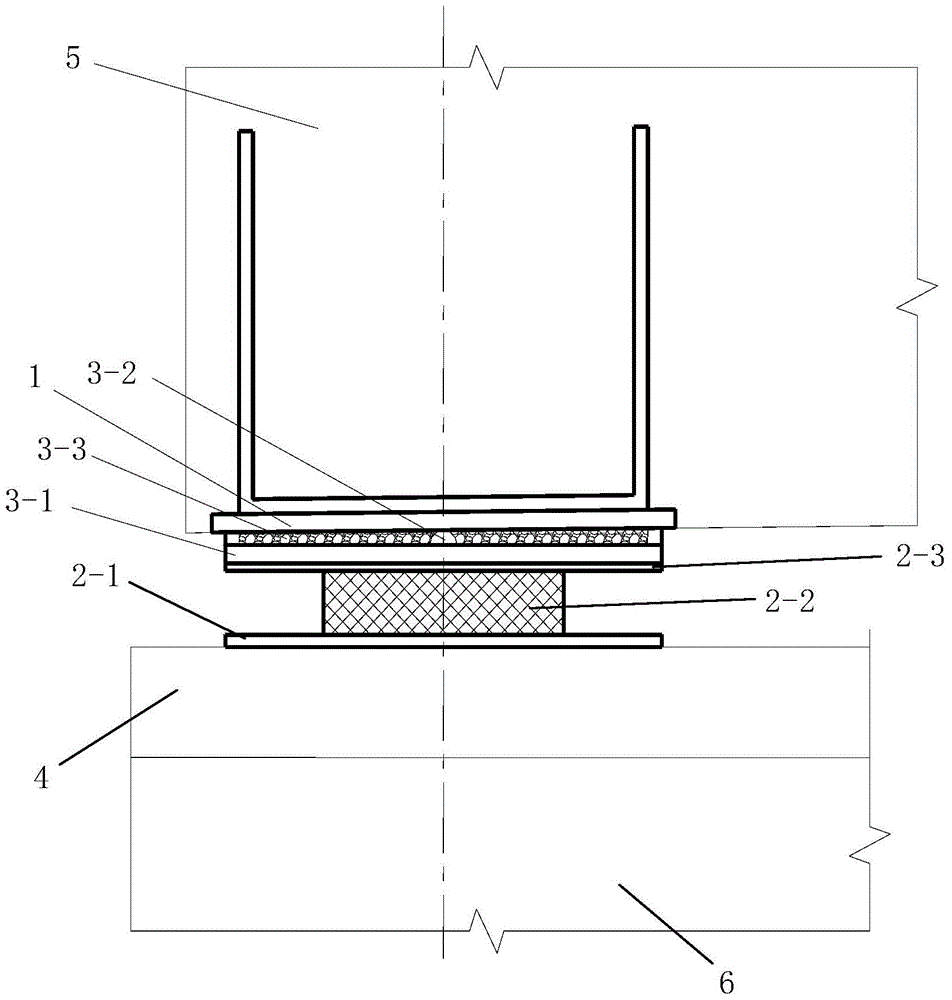

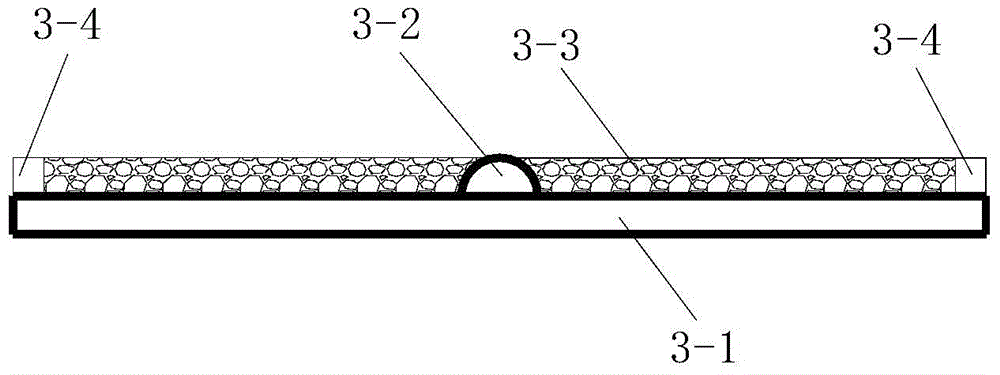

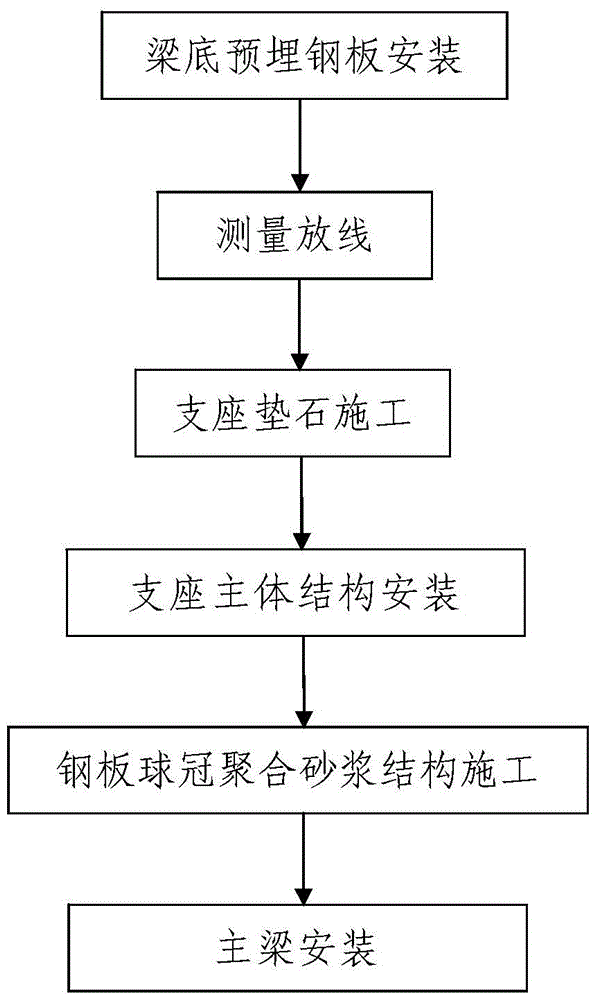

[0051] Such as figure 1 , figure 2 As shown, the steel spherical crown polymer mortar structure bearing of the present invention includes the bearing pad stone 4 arranged on the lower support structure of the bridge being constructed, the main support structure located above the bearing pad stone 4, and the embedded The beam bottom pre-embedded steel plate 1 at the bottom of the main girder 5 of the bridge being constructed and the steel plate spherical crown aggregate mortar structure between the beam bottom pre-embedded steel plate 1 and the main structure of the support, the main girder 5 is a reinforced concrete beam , the support pad 4 is a reinforced concrete structure. The steel spherical crown aggregated mortar structure is located above the main structure of the support, and the embedded steel plate 1 at the bottom of the beam, the aggregated steel plate spherical crown mortar structure, the main structure of the support and the support stone 4 are arranged from top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com