Standing type high-voltage cable operation device

A working device, high-voltage cable technology, applied in overhead lines/cable equipment, climate change adaptation, etc., can solve problems such as missing parts, broken strands, and large cable creeping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

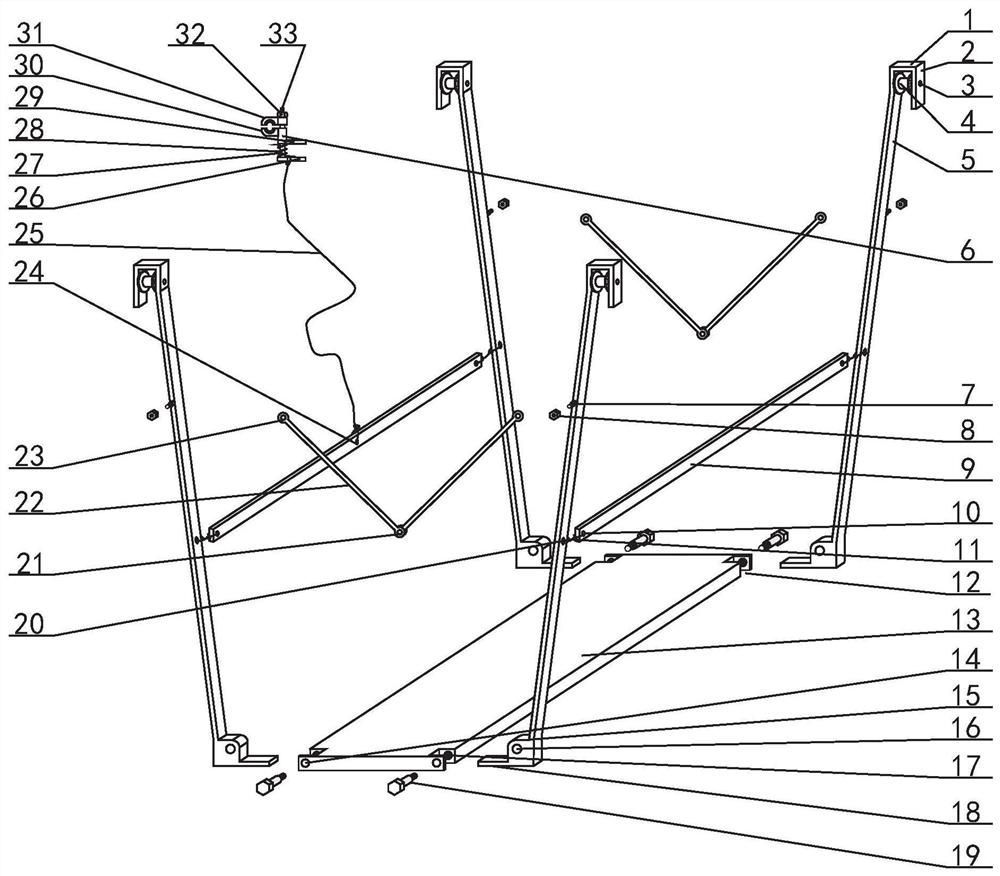

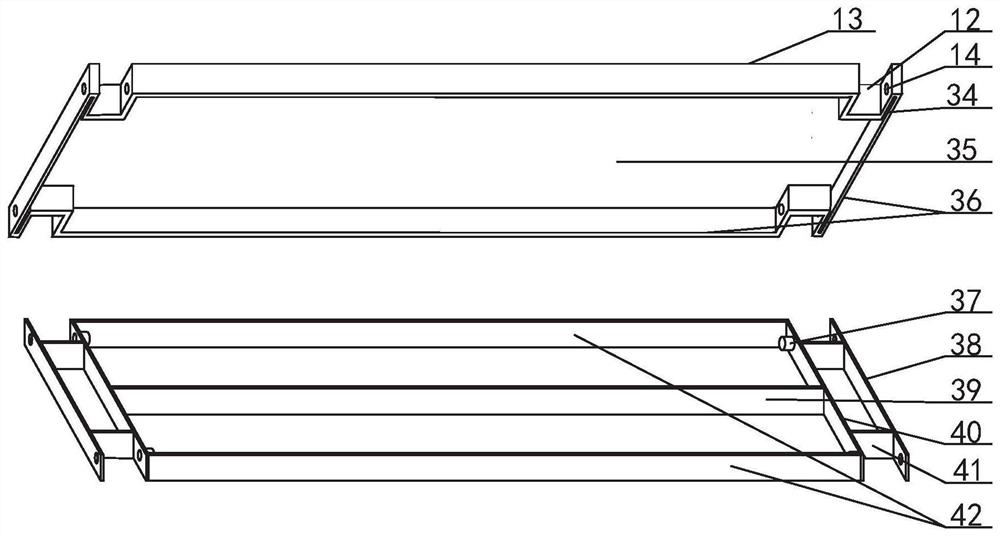

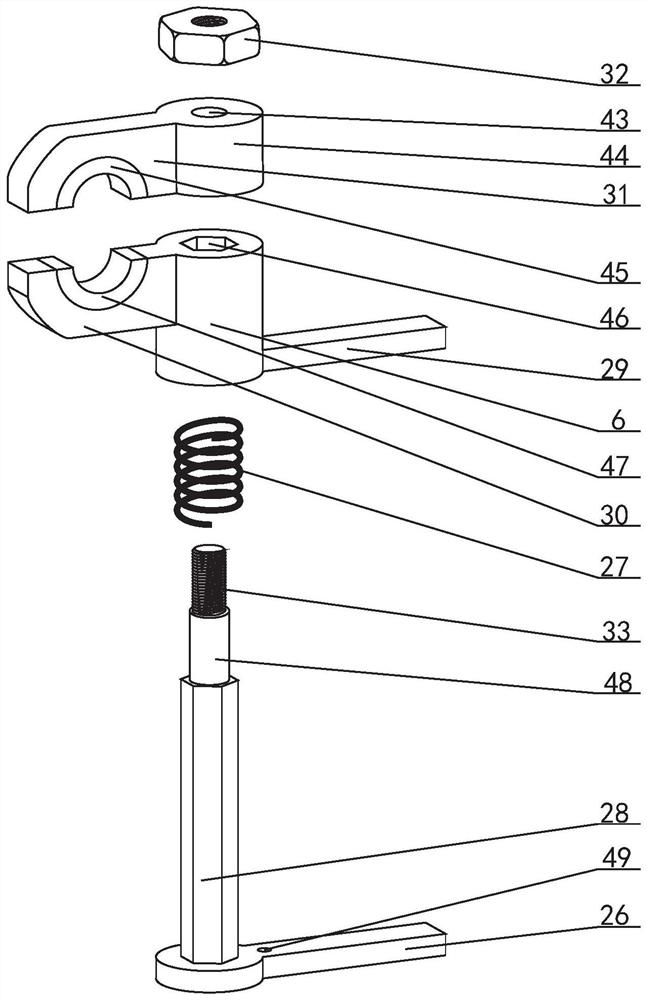

[0027] combined with Figure 1-7 The standing high-voltage cable working device described in includes a standing board 13, a vertical rod 5, a sheave 4, a telescopic rod 22, a retaining rod 9 and a cable lock device, and the two sides of the standing board 13 are respectively connected with four vertical rods near the front and rear ends. The lower ends of the 5 are hingedly connected, and sheaves 4 are respectively arranged on the outer sides of the upper ends of the four vertical rods 5, and telescopic rods 22 are respectively arranged between the vertical rods 5 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com