A high-voltage cable operation trolley

A high-voltage cable and trolley technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficult operation, large cable creep force, missing parts, etc., and achieve the effect of effective operation progress and accelerated operation progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

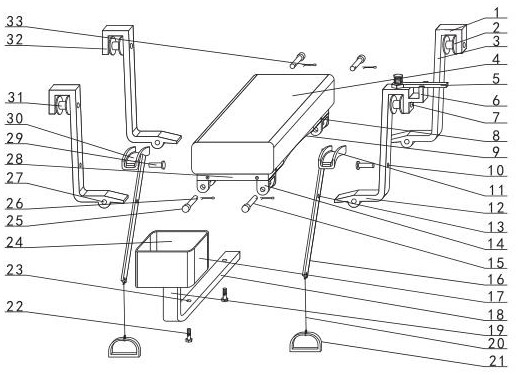

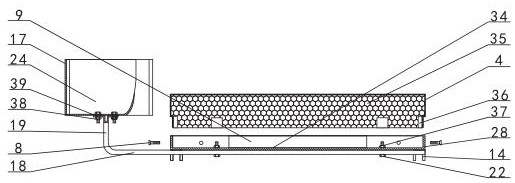

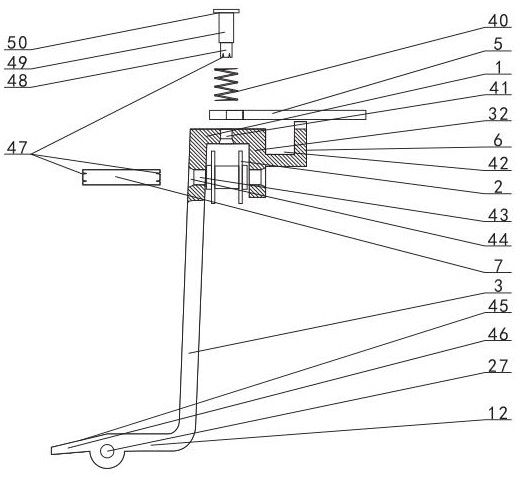

[0027] combined with Figure 1-8 The high-voltage cable operation trolley described in includes a cushion 4, a hanging arm, a sheave 2, a lever 16, a foot cover 21, a U-shaped plate 11 and a tool box 17. The lower ends of the vertical rods 3 are hingedly connected, and a sheave 2 is arranged on the outside of the upper end of each hanging arm vertical rod 3, and the middle parts of the vertical rods 3 on both sides of the front part of the seat cushion 4 are respectively provided with shaft holes A10, and the middle parts of the two levers 16 are respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com