Automatic drilling rod screw thread sealing grease spraying device and method

An automatic spraying and sealing grease technology, applied in the direction of spraying devices, etc., can solve the problems of potential safety hazards, poor application quality, and increased labor intensity, so as to improve the operation progress and timeliness, make the operation process fast and convenient, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

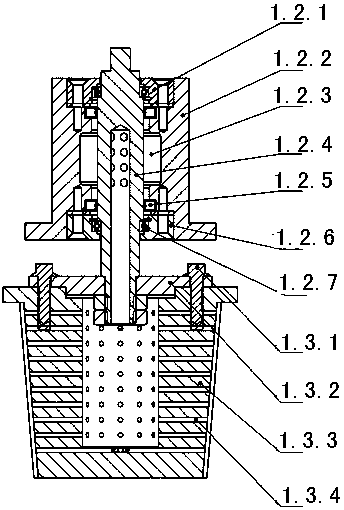

[0040] Embodiment 2, with reference to attached Figure 4 , The present invention differs from Embodiment 1 in that: the outer end of the above-mentioned vertical hydraulic lifting transfer mechanism 3 is connected to the female button spraying head 1-2 and the male button spraying head 1-1 simultaneously through the male and female button spraying switch 1-3.

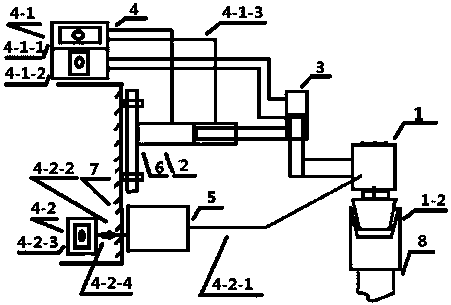

[0041] When working, the horizontal hydraulic transfer mechanism 2 is moved forward through the horizontal hydraulic control valve 4-1-1 of the control mechanism to reach the horizontal position of the drill pipe to be sprayed. 1-3, make it lead to the drill pipe pin, through the vertical hydraulic control valve 4-1-2 of the control mechanism, the vertical hydraulic lifting transfer mechanism 3 is moved upwards to reach the vertical position of the drill pipe pin to be sprayed, and then, through The air switch 4-2-3 of the sealing grease pneumatic control mechanism 4-2 supplies air to the sealing grease storage tank 5,...

Embodiment 3

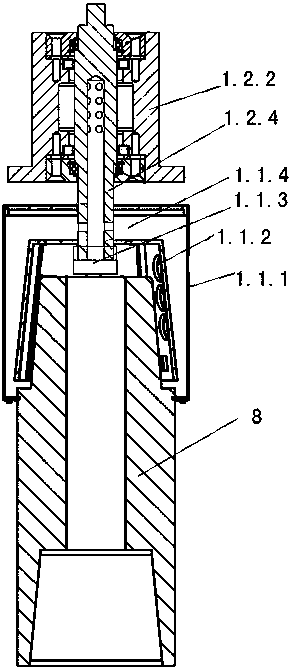

[0046] Embodiment 3, the difference between the present invention and Embodiment 1 is: the outer end of the vertical hydraulic lifting transfer mechanism 3 is connected to the male button spraying head 1-1 or the female button spraying head 1-2 through the male and female button spraying switch 1-3 , and combine the male and female button spraying switch 1-3 to realize the spraying of the male button or the female button of the drill pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com