Small excavator with double support arms

A kind of excavator, small-scale technology, applied in the direction of mechanically driven excavator/dredger, earth mover/shovel, construction, etc., can solve the problem of high rigidity requirements of backing plate, increase of backing plate thickness, cracking of surrounding welds, etc. problems, to achieve the effect of long service life, uniform force, and improved excavation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0028] The embodiment of the technical solution provided by the invention is:

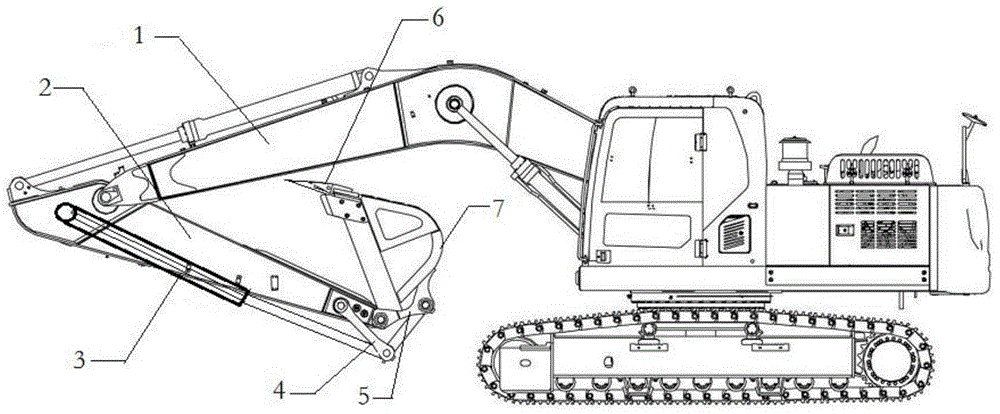

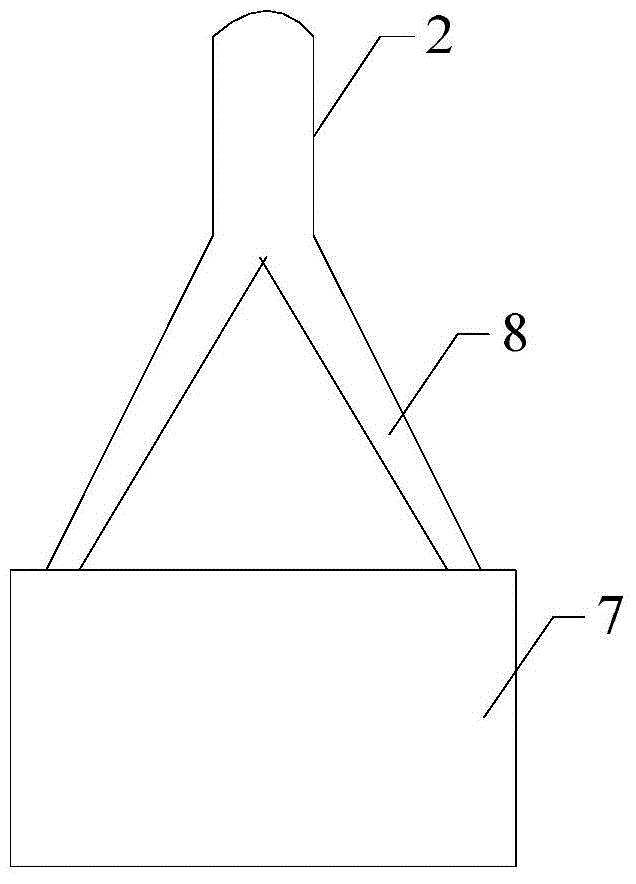

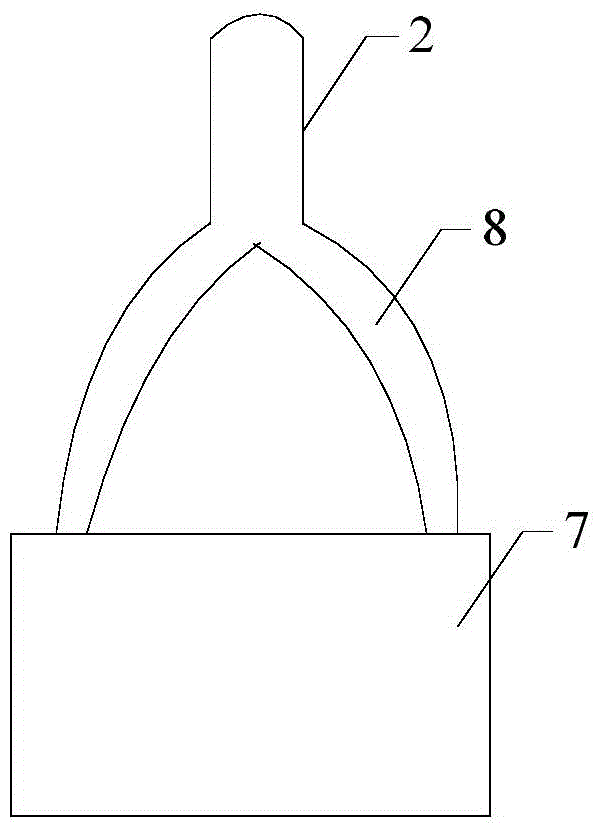

[0029] Such as figure 1 and figure 2 as shown,

[0030] In one embodiment, a small excavator with double arms is characterized in that it includes: an arm disposed between the boom and the bucket, the arm comprising a first bucket hinged end to end Rod 1 and second stick 2, the rear end of the first stick is hinged with the boom, the front part of the second stick is branched into two arms 8 of equal length, and the front ends of the two arms are connected to the The bucket is pivotally connected; two hinge seats 4 are respectively arranged at the pivot joints between the front ends of the two arms and the bucket; two arm cylinders 3 are respectively arranged on the outer sides of the two arms, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com