Earth excavation technology for ultra-large type deep foundation pit

An earth excavation and super-large technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of long time effect of support structure, increased construction cost, unfavorable force of support structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

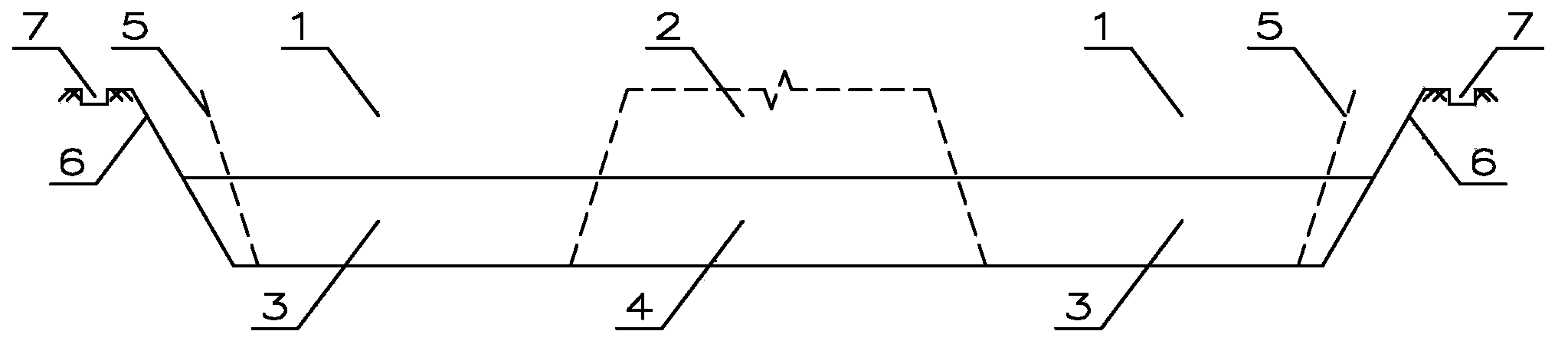

[0016] Such as figure 1 As shown, a kind of ultra-large deep foundation pit earthwork excavation technology described in the embodiment of the present invention comprises the following steps:

[0017] 1) After the setting-out measurement of the super-large deep foundation pit is completed, six areas are divided on the plane to organize the construction, and soil ramps are set between the areas;

[0018] 2) Basin-type excavation technology is adopted in the boundary areas 1 and 3 of the foundation pit. The soil mass in the middle is constructed first, and the surrounding soil mass is excavated later. 6. Build the slope support structure in time;

[0019] 3) Island excavation technology is adopted in the middle areas 2 and 4 of the foundation pit, and the soil in the adjacent boundary areas 1 and 3 is constructed first, and then the middle soil is excavated, and the transition with the adjacent boundary areas 1 and 3 is comprehensively considered Stablize;

[0020] 4) Moreove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com