Tunnel engineering mining method excavation blasting instantaneous dust fall process

A technology for tunnel engineering and tunnel excavation, which is applied in the fields of dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of dust pollution on the excavation surface, tight construction period, and long blasting excavation, and achieves short dust removal time and cost. The effect of low cost and speeding up the progress of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

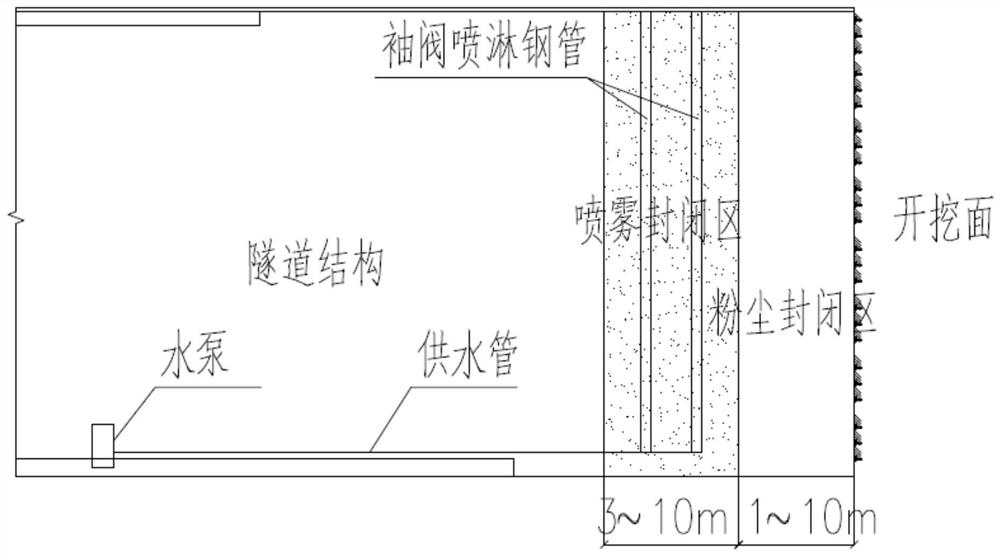

[0016] 1. Spray technical requirements:

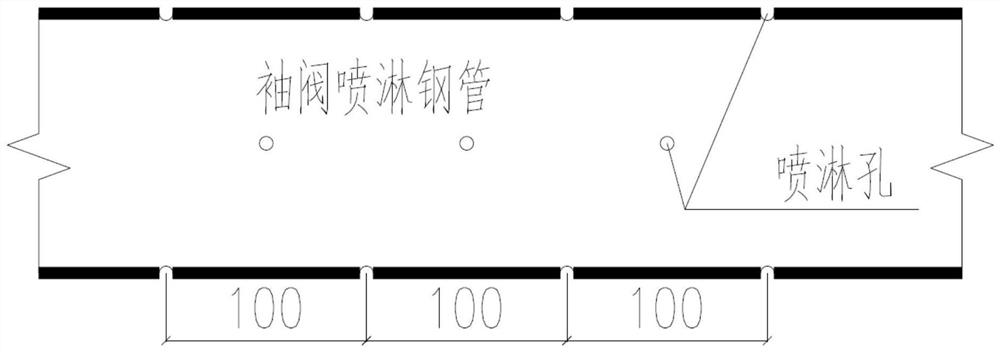

[0017] (1) Spray pipe: adopt φ20mm hot-rolled seamless steel pipe, wall thickness 1mm, reserved nozzle installation hole diameter 5mm, longitudinal distance between holes 100mm, evenly arranged at 90-degree circumferential interval, arranged in plum blossom shape, two adjacent The longitudinal spacing of spray pipes is 0.8m;

[0018] (2) Nozzle: Spray aperture 0.1mm, external thread diameter of connection end 4.5mm, connected with spray pipe by welding rod;

[0019] (3) Suction pump: 220v, 1100W, 10m head submersible pump;

[0020] (4) Spray parameters: working pressure 3.5Mpa, spray flow rate 2L / min, single nozzle spray range diameter greater than 1m, main droplet size less than 50um, 600 droplets / (cm 2 min).

[0021] 2. Drill holes and install waterproof emulsion explosives on the excavation surface of the tunnel;

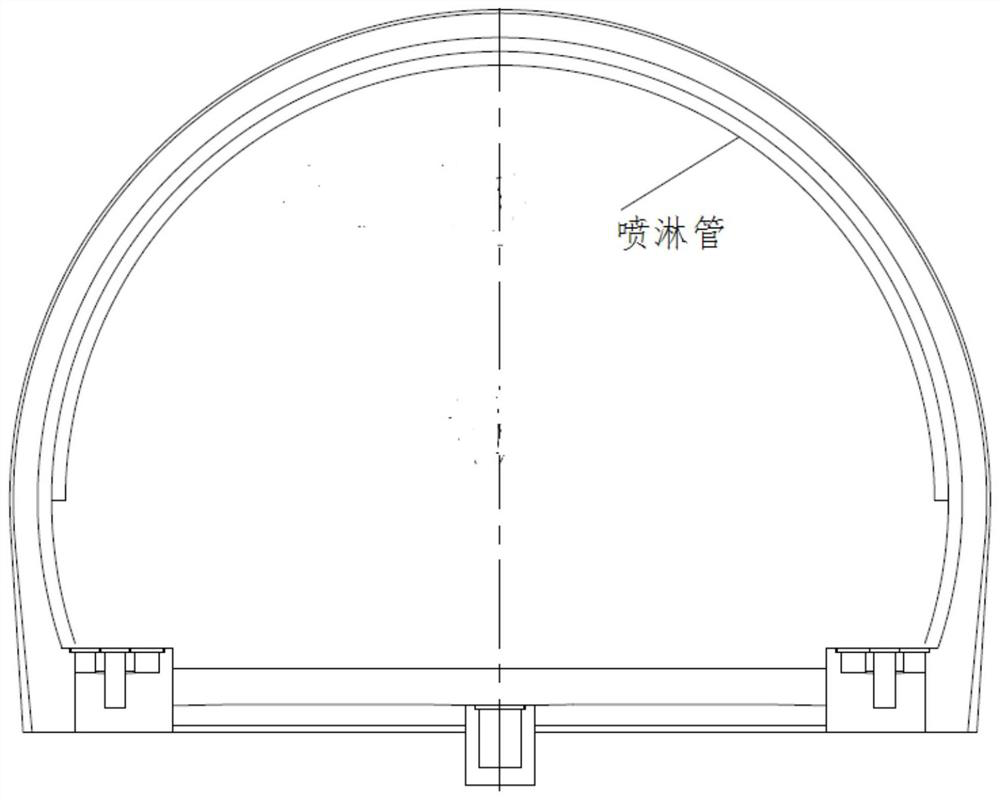

[0022] 3. The arched simple sleeve valve steel pipe mist spray equipment is used at the vault of the tunnel within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com