A fishing device and method for a sand-buried pipe string in an oil-water well

A salvage device and string technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve the problems of inaccurate prediction and control of workover period and cost, casing aging, time-consuming and labor-intensive timing, etc. Achieve the effect of saving operation cost and construction period, speeding up operation progress and reducing salvage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

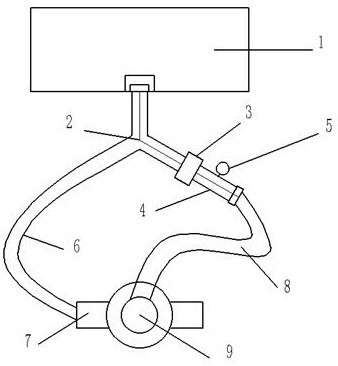

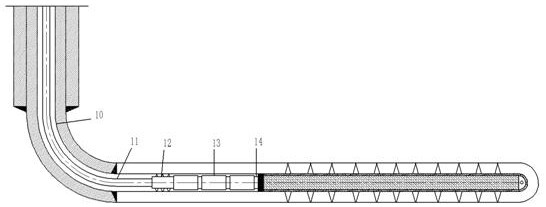

[0030] as attached Figure 1 to Figure 2 As shown, a salvage device for an underground sand-buried pipe string in an oil-water well, including a ground pressure pipeline and a downhole fishing string composed of an oil pipe, a hydraulic anchor, a booster, and a fishing tool. The ground pressure pipeline includes a first high-pressure pipeline 6. The second high-pressure pipeline 8, the starting ends of the first high-pressure pipeline and the second high-pressure pipeline are respectively connected to two branch ports of the same tee 2, and the main inlet of the tee is connected to the pump truck 1, and the first The end of the high-pressure pipeline is connected to the tubing joint 9 at the upper port of the downhole fishing string, and the end of the second high-pressure pipeline is connected to the casing valve 7 at the wellhead.

[0031] A pressure test cylinder 4 is arranged between the first high-pressure pipeline and the tee, and a pressure gauge 5 is installed on the p...

Embodiment 2

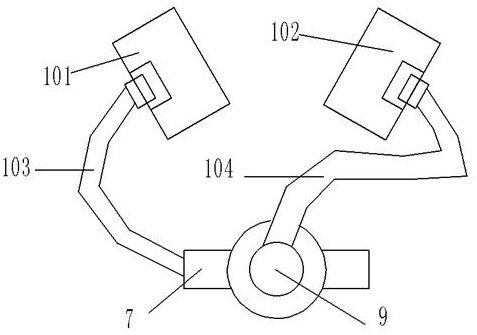

[0038] according to figure 2 with image 3 As shown, some of the following labeled components do not appear in drawing 3, but can be based on figure 1 As can be seen from the following text introduction, the description of the connection relationship between components is clear.

[0039] A fishing device for an underground sand-buried pipe string in an oil and water well, comprising a ground pressure pipeline and an underground fishing pipe string composed of an oil pipe, a hydraulic anchor, a booster, and a fishing tool, characterized in that the ground pressure pipeline includes a first high-pressure pipeline, the second high-pressure pipeline, the beginning ends of the first high-pressure pipeline and the second high-pressure pipeline are respectively connected to the pump truck 1 and the pump truck 2, and the end of the first high-pressure pipeline is connected to the oil pipe joint at the upper port of the downhole fishing string. The end of the second high-pressure pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com