Small size multifunction heading machine

A multi-functional, roadheader technology, applied to cutting machinery, earthwork drilling and mining, etc., can solve problems such as increasing operating costs, affecting operation progress, and limiting the use of roadheaders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

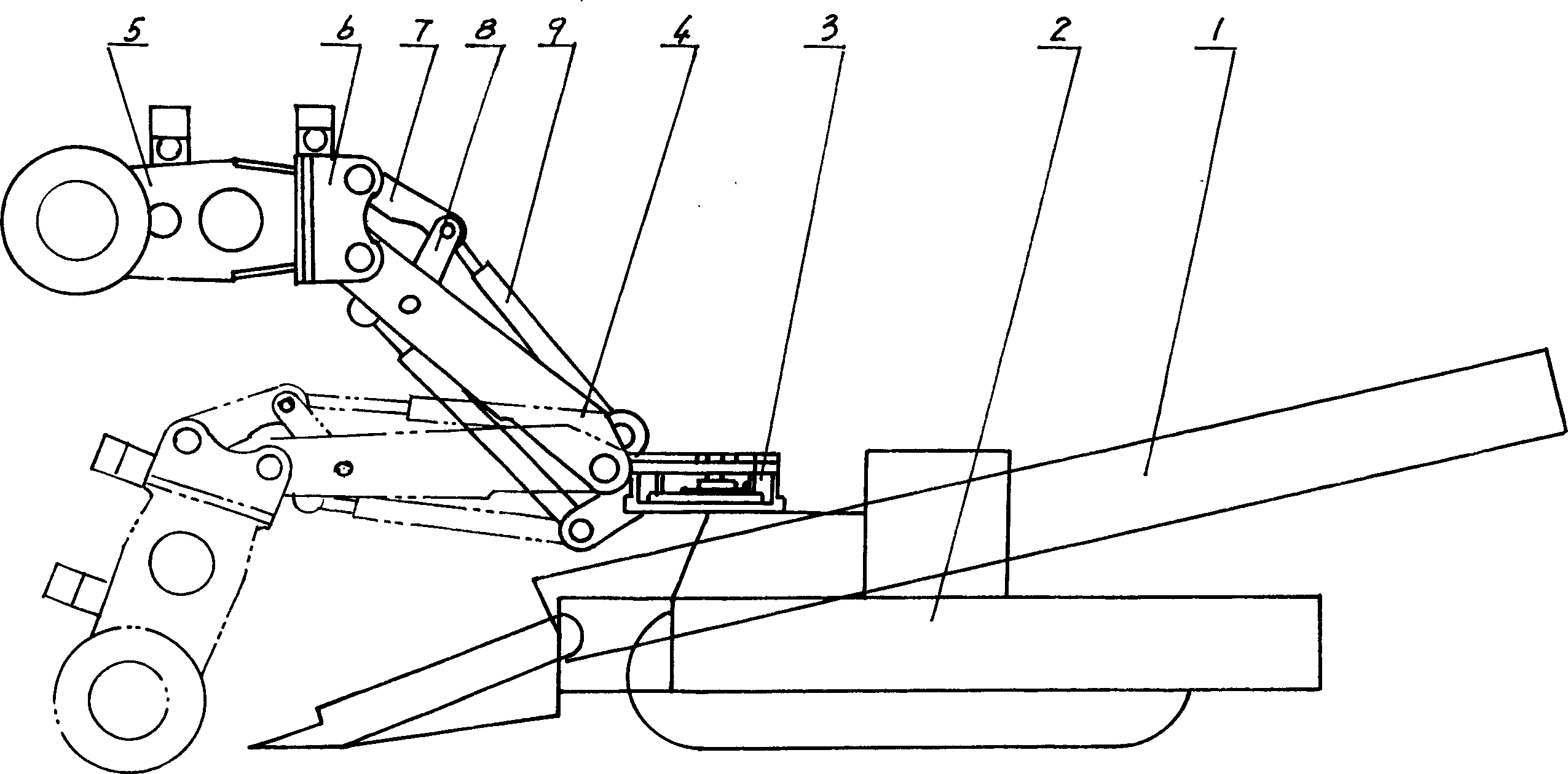

[0008] Accompanying drawing is an embodiment of the present invention, and it comprises self-propelled crawler chassis 2, scraper loader 1, cutting arm 4, cutting arm connecting device 3, articulated swing device, cutting head can move left and right cutting head Device 5 etc. The pick-up machine 1 and the cutting arm coupling device 3 are all fixed on the self-propelled crawler chassis 2, one end of the cutting arm 4 is hingedly connected with the cutting arm coupling device 3, and the hinged swinging device is hingedly connected with the other end of the cutting arm 4 , The cutting head device 5 is installed on the hinged swing device and is detachably connected. There are many structural forms of the hinged swing device, and the present embodiment includes hinged disc 6, swing cylinder 9, swing rod I7, swing rod II8 and the like. Hinged disc 6 is hingedly connected with cutting arm 4, swing cylinder 9, swing bar I7, and swing bar II8 are hingedly connected together, the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com