Static blasting expansion agent filling equipment and method

A technology of static blasting and expansion agent, which is applied to static blasting expansion agent injection equipment, static blasting expansion agent injection equipment and the field of injection, which can solve the problems of long time-consuming injection of static blasting expansion agent, and achieve health damage avoidance, good blasting effect, The effect of high blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

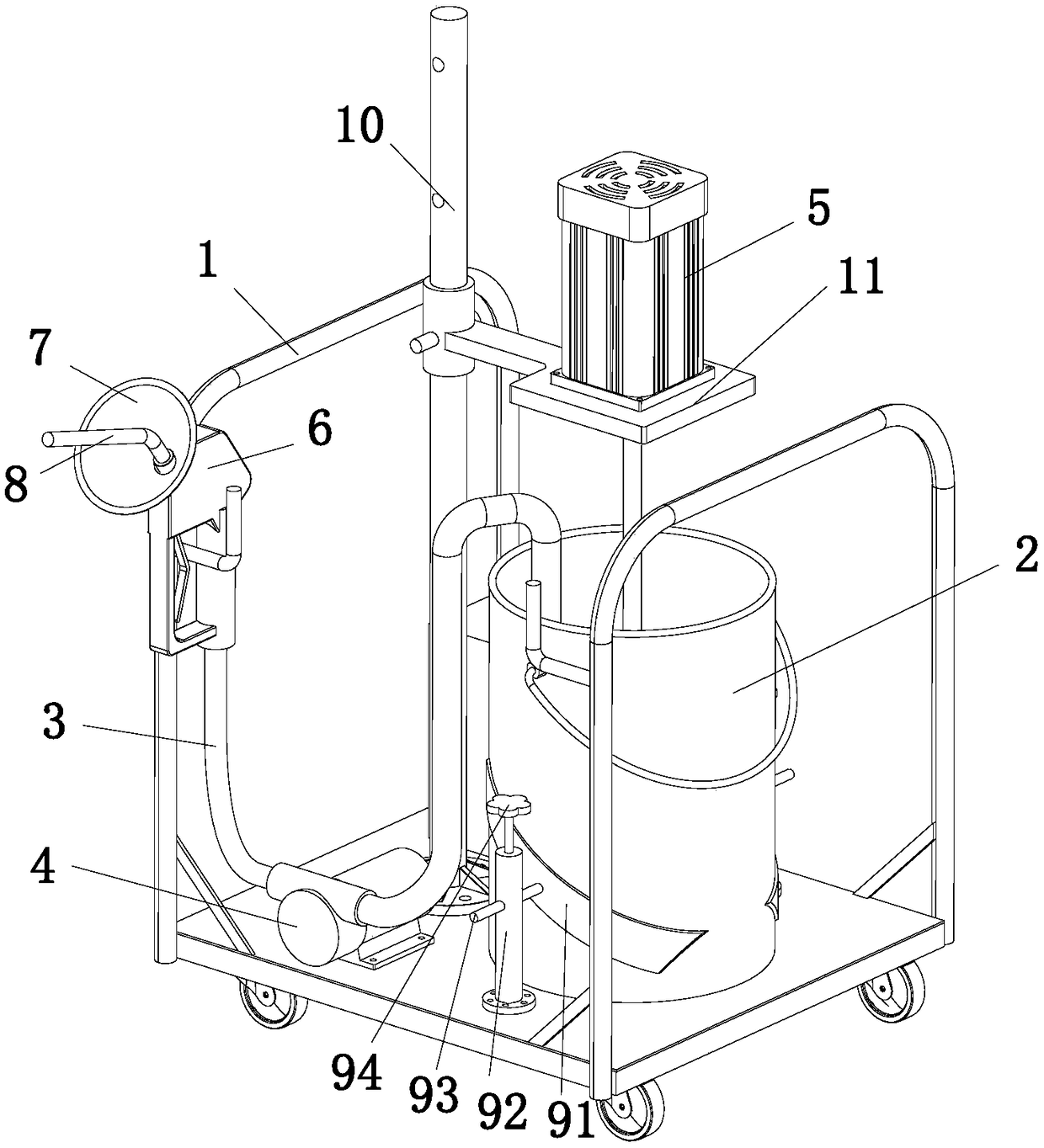

[0022] figure 1 It is a structural schematic diagram of a preferred embodiment of the present invention.

[0023] like figure 1 As shown, the static blasting expansion agent filling equipment of the present embodiment includes a vehicle frame 1 for mobile equipment, a material barrel 2 for containing the blasting expansion agent on the vehicle frame 1, and a material barrel 2 located on the vehicle frame 1. A stirring device 5 for stirring the blasting expansion agent in the material barrel 2, a delivery pipeline 3 for transporting the blasting expansion agent in the material barrel 2 to the blasthole, and a blasting expansion agent for the blasting expansion agent in the delivery pipeline 3. The driving device 4 for agent delivery power. The driving device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com