Channeling method in rapid roadway explosion

A fast and well-tunneling technology, which is applied in the field of mine excavation, can solve the problems of low cutting blasting efficiency and affecting the excavation speed, etc., and achieve the effect of increasing the blasting depth, blasting efficiency, and excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

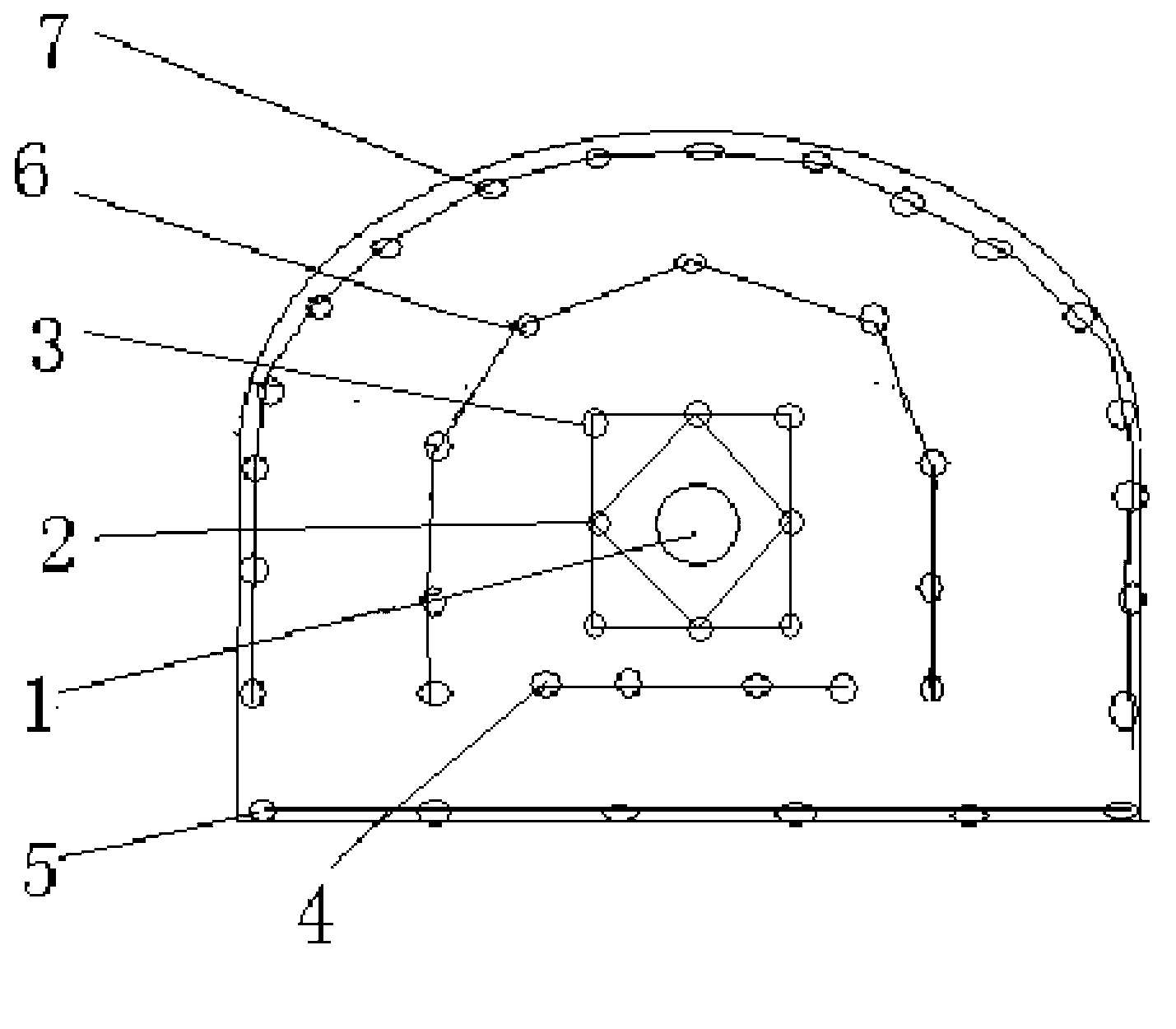

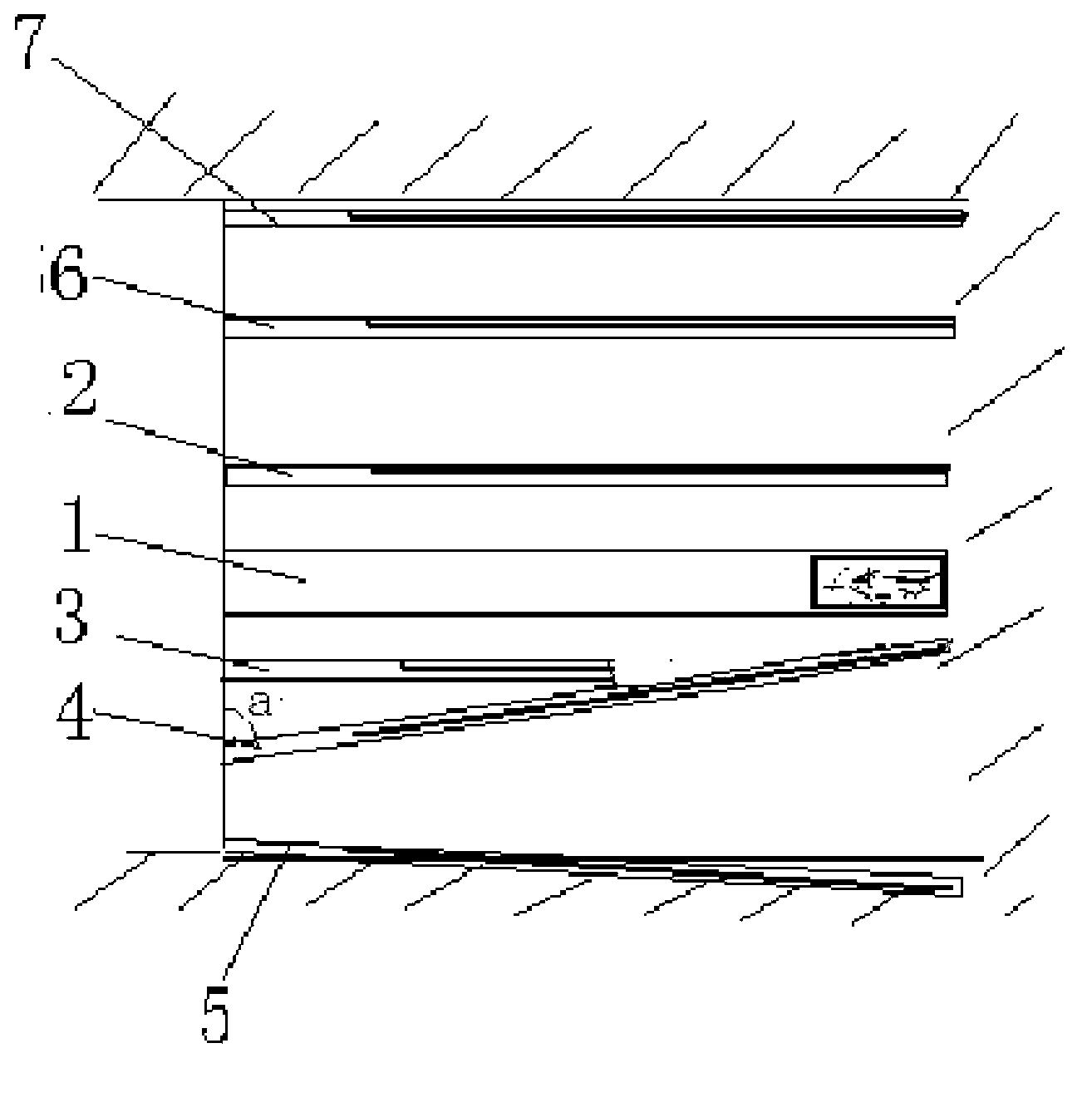

[0013] Such as figure 1 , figure 2 As shown, a cutting method for rapid blasting in a roadway, it is in the center of the cutting area of the roadway section, using down-the-hole drilling to drill a central hole 1 with a diameter of φ100-120mm and a depth of more than 4m; There are 4 broken and expanded holes 3 of common diameter arranged around, the depth of the broken and expanded holes 3 is consistent with that of the center hole 1, the distance between the centers of the broken and expanded holes 2 and the center hole 1 is 0.5-1.0 meters, and the distance between the broken and expanded holes 4 and the center hole 1 The axis direction is consistent; a row of broken holes 2 is arranged between the broken and expanded holes 2, and the depth of the broken holes 2 is 0.5 times that of the broken and expanded holes 3, which are used to break large rocks; Arrange a row of auxiliary throwing holes 4 with a spacing of 0.5 meters. The drilling direction of the auxiliary throwin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com