Closed free surface slotting blasting method capable of improving blasting efficiency

A free and efficient technology, applied in blasting, earth cube drilling, mining equipment, etc., can solve problems such as large clamping effect, single free surface, complex working environment, etc., to improve cutting efficiency, reduce consumption, and improve construction safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

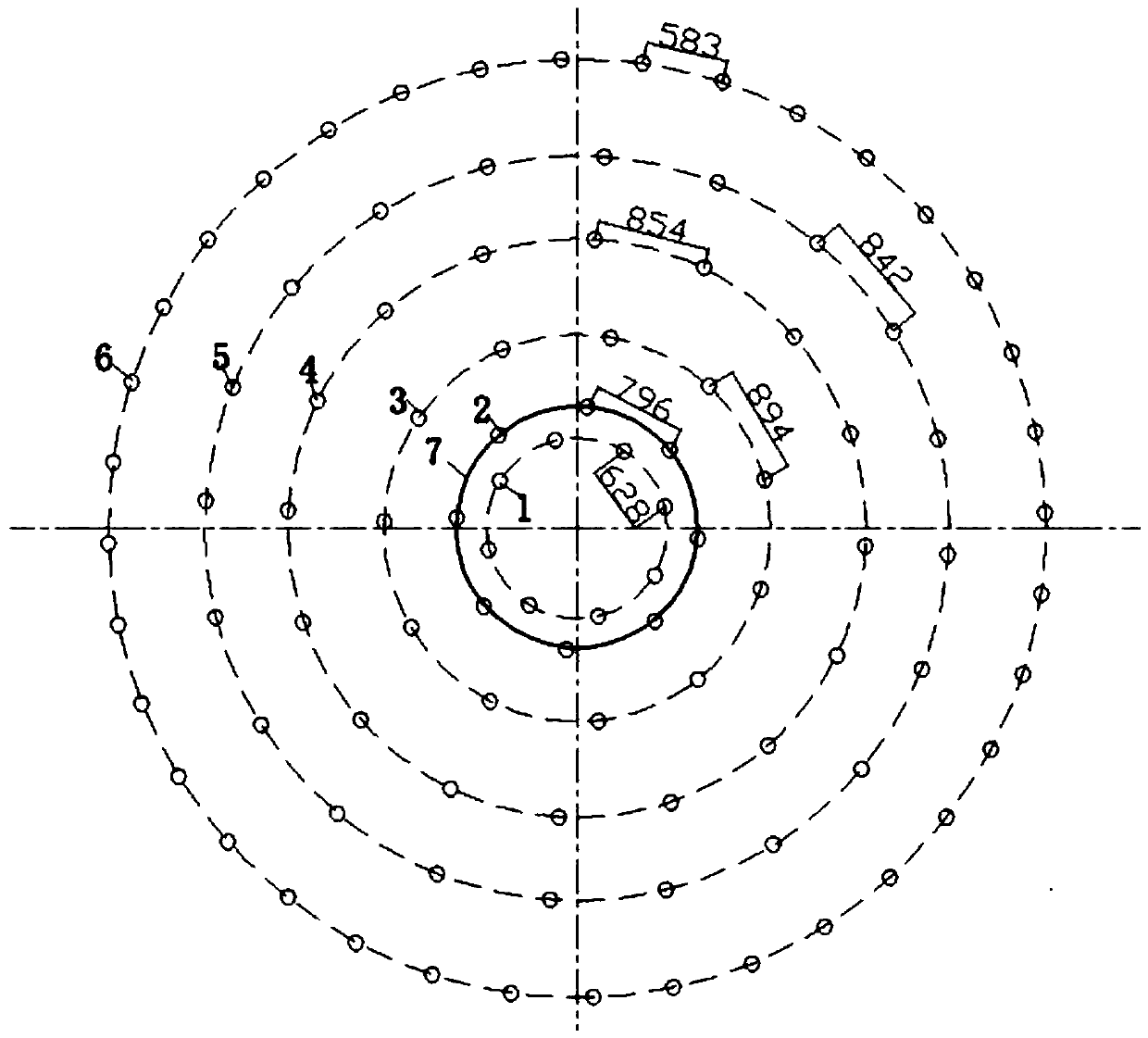

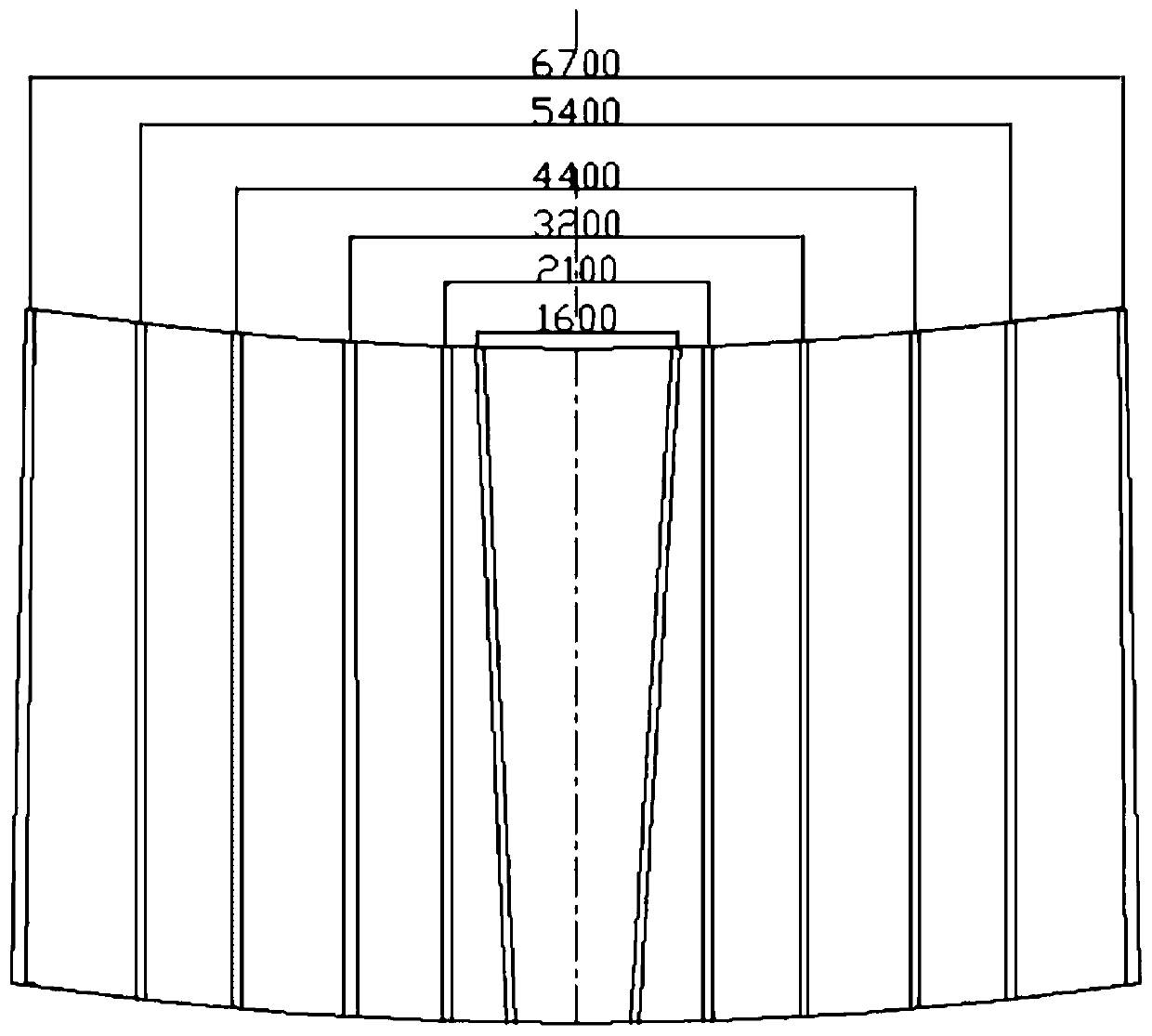

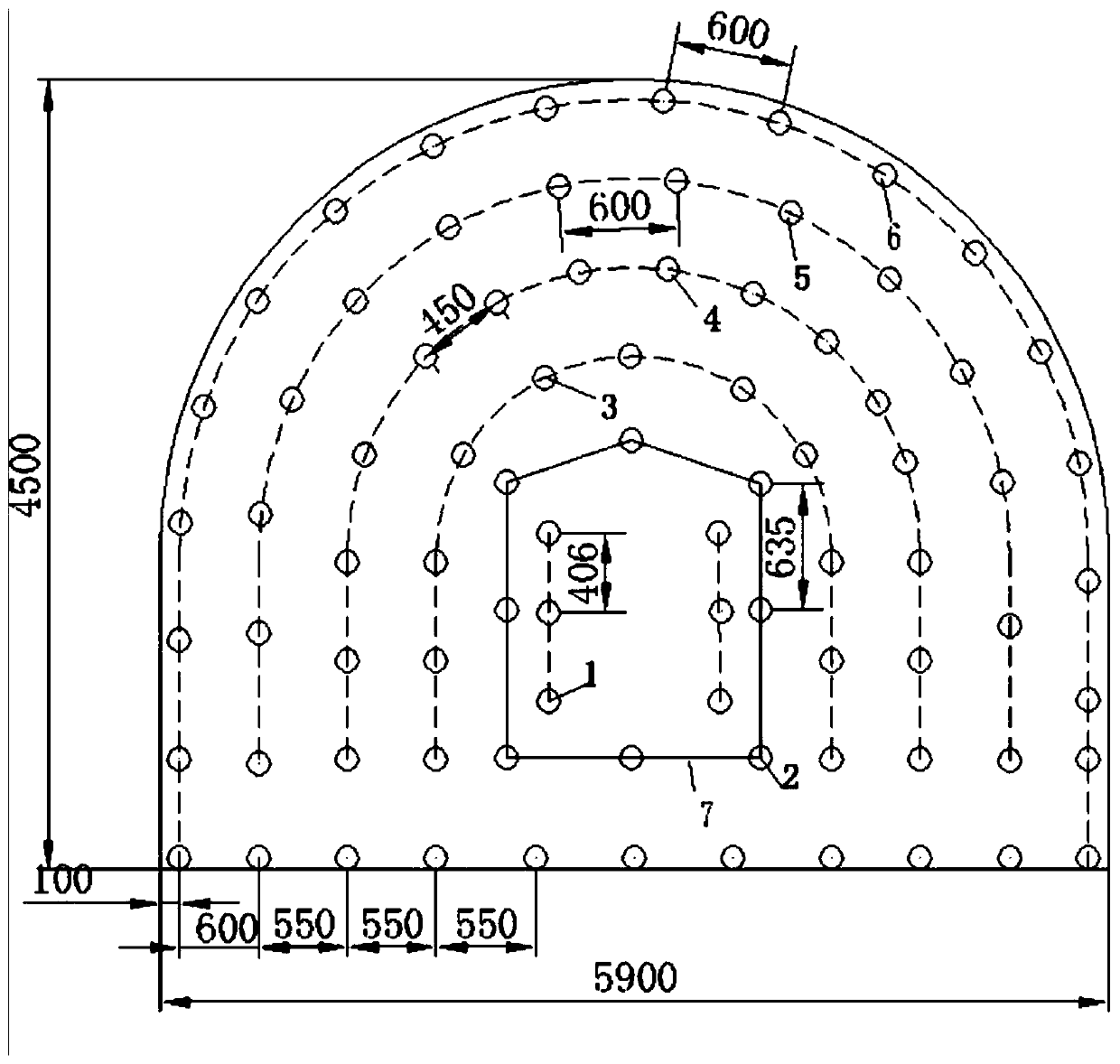

[0044] figure 1 and figure 2 The vertical shaft blast hole layout based on the closed free surface cut is given, image 3 and Figure 4 The layout of blastholes in level lanes based on closed free surface cuts is given, including cut holes 1, cut holes 2, auxiliary holes 3 in the first circle, auxiliary holes 4 in the second circle, auxiliary holes 5 in the third circle, peripheral holes 6 and closed free surface 7.

Embodiment 2

[0046] refer to Figure 5 , 6 , for use when the lithology is relatively hard or poor. On the basis of Example 1, an empty hole 8 is arranged between the two cutting holes 2 .

Embodiment 3

[0048] Figure 7 A schematic diagram of a blasting tube with control over the direction of crack propagation is given, including an explosive cavity 9 filled with explosives, a cavity 10 equipped with wave-stopping materials such as rubber pads and soft cloth, and an energy-dissipating joint 11 with an energy-dissipating joint angle 12 of 60° .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com