Drilling machine direction angle monitoring method and system

A technology of monitoring system and direction angle, which is applied in the directions of measuring devices, measuring angles, surveying and navigation, etc. It can solve problems such as downtime, affecting work efficiency, large deviation drilling, etc., and achieves the effect of convenient use and high monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A method for monitoring the direction angle of a drilling machine, which at least consists of two parts: a measurement controller and a hand-held instrument. Set the measurement controller on the drilling rig or on the beam of the drilling rig, and use the hand-held instrument to see whether the azimuth angle deviates within the allowable range. If there is a deviation, an alarm will be given, and it will be manually selected whether to continue drilling. During the monitoring process, the drilling The machine does not need to stop.

[0016] The appearance of the measurement controller is a rectangular plastic shell, which contains an electronic compass for azimuth measurement, a gyroscope for measuring inclination, a rechargeable battery, a Bluetooth communication module and an alarm indicator.

[0017] The electronic compass and gyroscope are used to monitor the variation between the changed azimuth angle of the drilling rig and the initial azimuth angle...

Embodiment 2

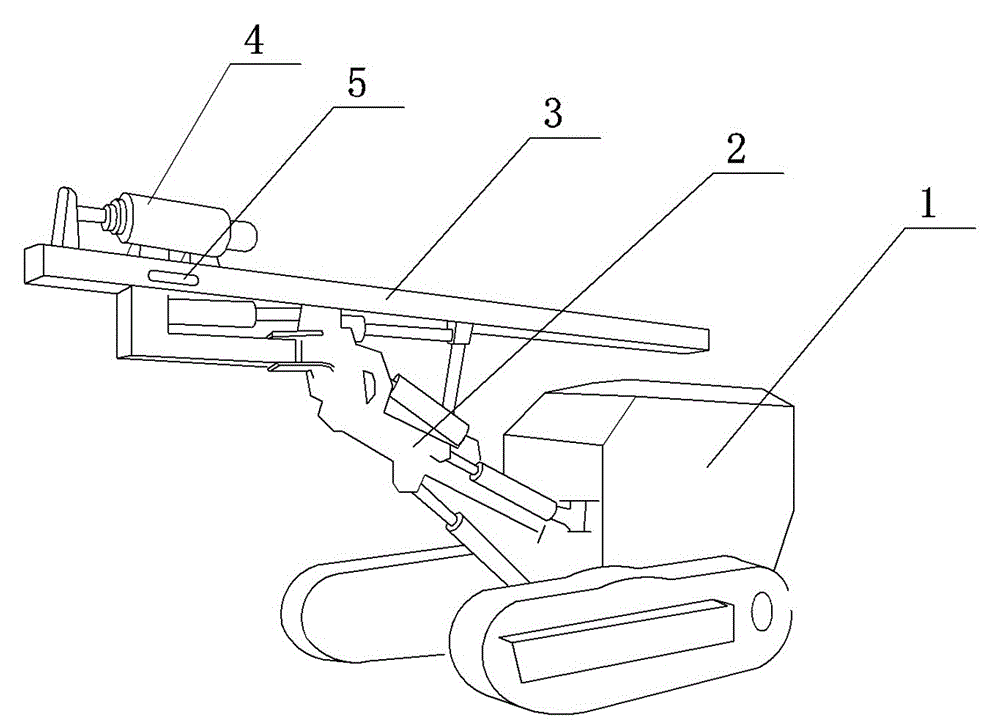

[0035] Embodiment 2: A drilling machine orientation angle monitoring system, including a measurement controller and a hand-held instrument, the hand-held instrument is a mobile phone. Such as figure 1 , can be combined with the crawler vehicle 1, a crossbeam 3 is installed above the control moving mechanism 2 provided at the front end of the crawler vehicle 1, the drilling rig 4 is fixed above the crossbeam 3, and the casing of the measurement controller 5 is fixed on the drilling rig through the attached metal fittings or on the Rig beam 3 on.

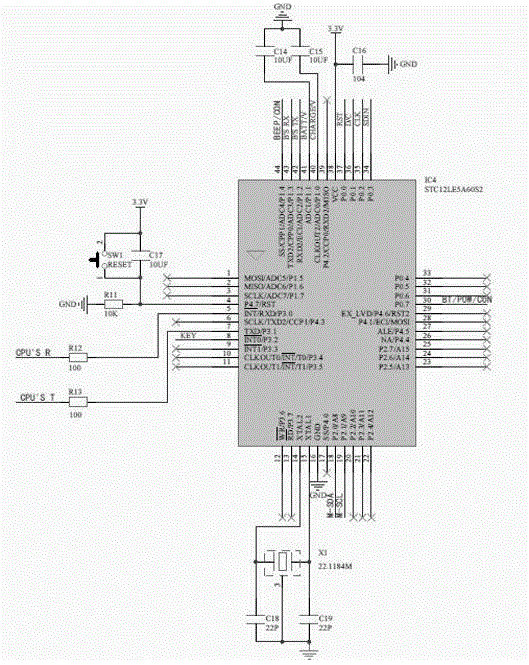

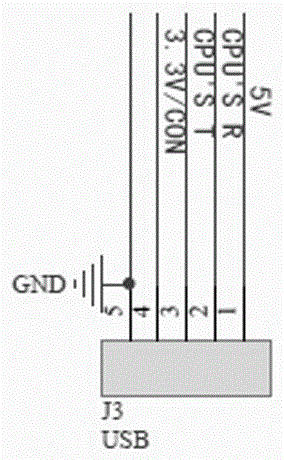

[0036] The measurement controller includes an electronic compass for azimuth measurement, a gyroscope for measuring inclination, a rechargeable battery, a Bluetooth communication module and an alarm indicator light. Its circuit principle is as follows: Figure 2-Figure 10 The connections shown. The housing of the measuring controller is fixed on the boom of the punching machine through the attached metal fittings. The handheld devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com