Method for blasting and excavating dam foundation and rock foundation

A technology for rock and dam foundation, applied in the field of engineering blasting, can solve the problems of limited blasting shock wave buffering effect, inability to achieve ideal effects, and large damage to the bottom of blasting holes, and achieve the effects of improving blasting efficiency, reducing bottom damage and low construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

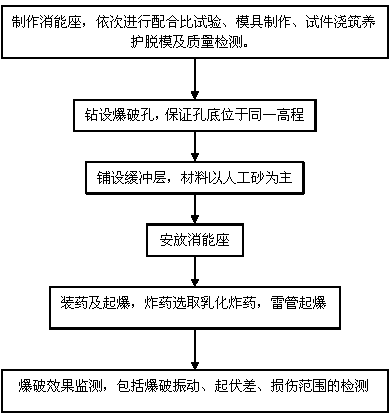

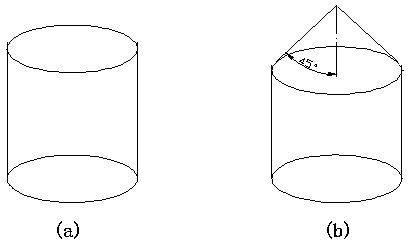

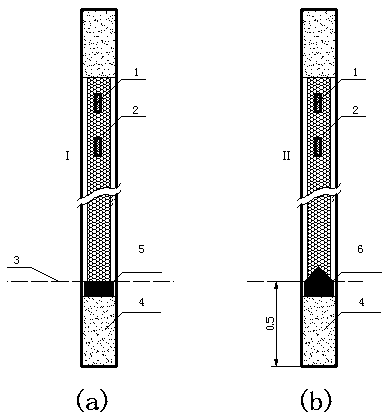

[0047] In Example 1, a cylindrical energy dissipation seat is set at the bottom of the blast hole, see image 3 Middle I area; cone column energy dissipation seat is set at the bottom of the blast hole in Example 2, see image 3 Middle II area.

[0048] The concrete implementation process for above-mentioned embodiment is as follows:

[0049] 1. Production of concrete energy dissipation seat.

[0050] In order to reduce the cost and facilitate the construction and manufacture of the energy dissipation pad, it is planned to use high wave impedance concrete to make the energy dissipation seat. The manufacture of the energy dissipation seat includes mix ratio test, mold making and quality inspection.

[0051] (1) Mixing ratio test.

[0052]Under ideal conditions, the best effect is to use cast iron to form the energy dissipation seat. However, due to the difficulty of processing and high cost, it is considered to use high-wave impedance concrete mortar materials to prepare th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com