High-energy physics fracturing device

A high-energy physics and fracturing technology, which is applied in weapon accessories, blasting cylinders, discharging machinery, etc., can solve the problems of inability to monitor the gas concentration at the blasting site, single medium, and inability to clearly monitor the working state of the medium phase change cracker. Improve blasting efficiency, low cost, and ensure the effect of mining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment A high-energy physical fracturing device, including a control terminal, a number of medium phase change crackers connected to the control terminal, and the control terminal monitors and controls the working status of the medium phase change crackers connected to it;

[0026] The medium phase change cracker includes a storage tube, a constant pressure energy release device, an energy guide device, a trigger device, a controller, a fixing device, a pressure sensor, a gas concentration detection sensor, and a battery; the storage tube is used to store liquid medium, The trigger device is connected to the storage tube. When the trigger device is triggered, the liquid medium in the storage tube is heated to make it into a gaseous state. The controller is arranged outside the trigger device to control the working state of the trigger device , the constant pressure energy release device is arranged at the outlet of the storage tube, and when the pressure received by ...

specific Embodiment approach 1

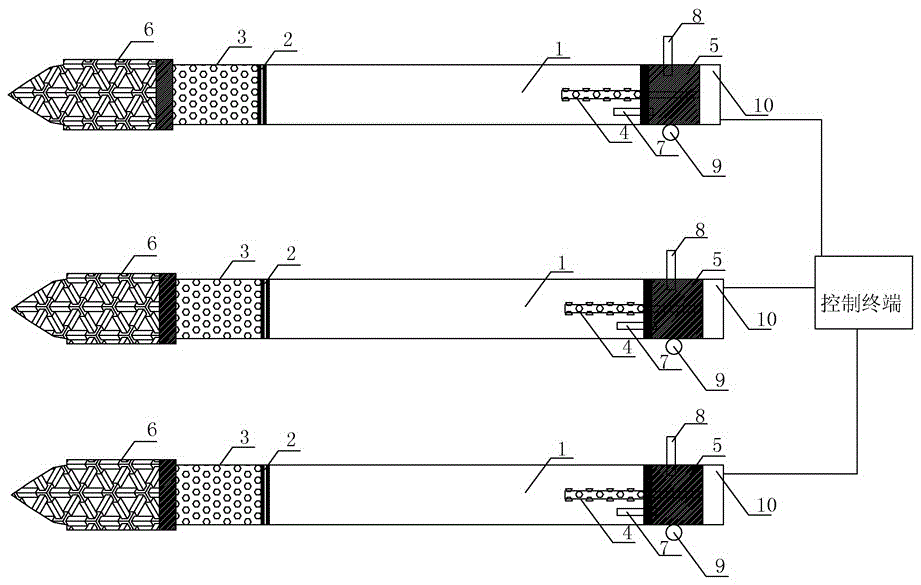

[0031] Specific implementation mode 1, such as figure 1 As shown, a high-energy physical cracking device includes a control terminal, a number of carbon dioxide crackers connected to the control terminal, and the control terminal monitors and controls the working status of the carbon dioxide crackers connected to it;

[0032] The carbon dioxide cracker includes a storage tube 1, a constant pressure energy release device 2, an energy guiding device 3, a trigger device 4, a controller 5, a fixing device 6, a pressure sensor 7, a gas detection sensor 8, and a battery 10; The tube 1 is used to store liquid carbon dioxide. The trigger device 4 is connected to the storage tube 1. When the trigger device 4 is triggered, the liquid carbon dioxide in the storage tube 1 is heated to make it into gaseous carbon dioxide. The controller 5 is arranged on the The outside of the trigger device 4 controls the working state of the trigger device 4. The constant pressure energy release device 2 ...

specific Embodiment approach 2

[0038] Specific implementation mode 2 such as figure 1 As shown, a high-energy physical cracking device includes a control terminal, a number of nitrogen crackers connected to the control terminal, and the control terminal monitors and controls the working status of the nitrogen crackers connected to it;

[0039] The nitrogen cracker includes a storage tube 1, a constant pressure energy release device 2, an energy guiding device 3, a trigger device 4, a controller 5, a fixing device 6, a pressure sensor 7, a gas detection sensor 8, and a battery 10; The tube 1 is used to store liquid nitrogen, and the trigger device 4 is connected to the storage tube 1. When the trigger device 4 is triggered, the liquid nitrogen in the storage tube 1 is heated to make it into gaseous nitrogen, and the controller 5 is arranged on the The outside of the trigger device 4 controls the working state of the trigger device 4. The constant pressure energy release device 2 is arranged at the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com