A blasting method for directional fracture and slotting of mixed wedge-shaped kerf charges in hard rock roadways

A technology of directional fracture and roadway, which is applied in blasting and other directions, can solve the problems of high rate of over-broken rock blocks, influence on construction progress, and heavy drilling workload, so as to achieve moderate construction difficulty and cost, increase aperture distance and Row spacing, effect of securing strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

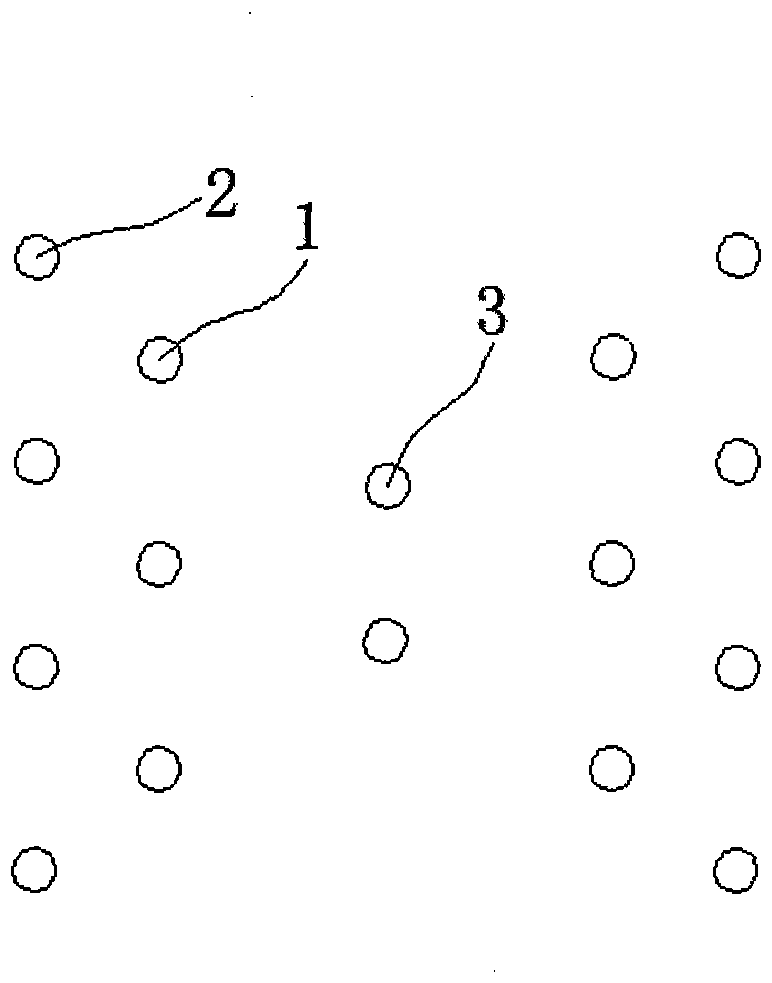

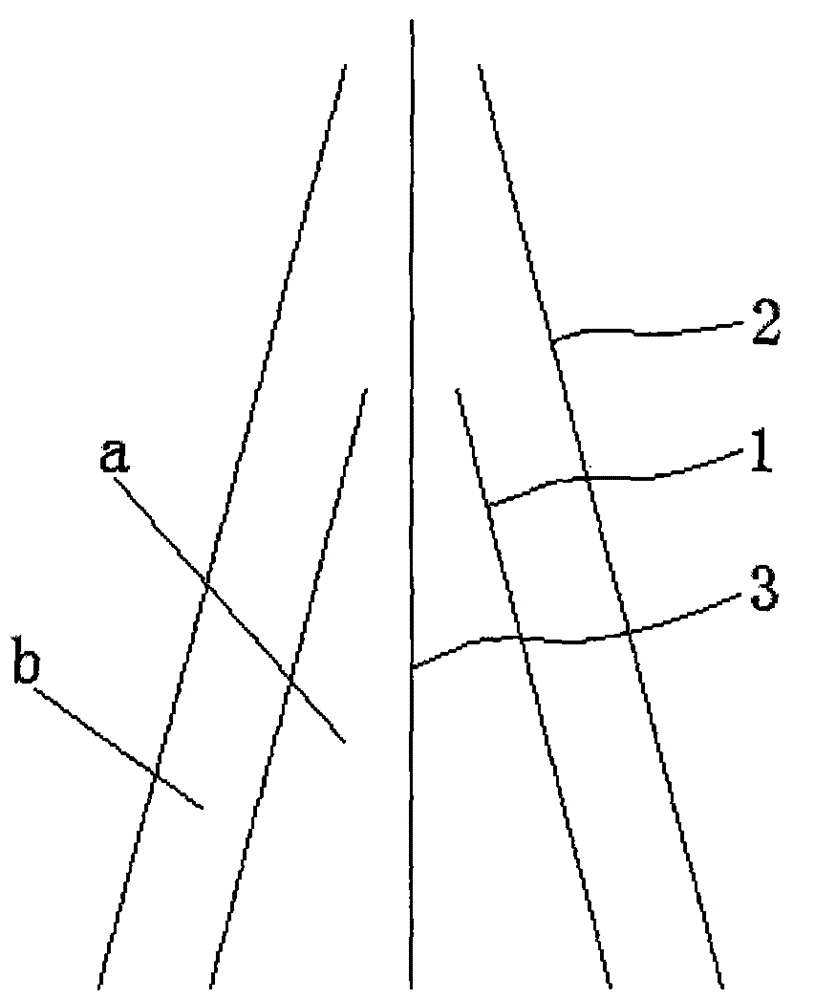

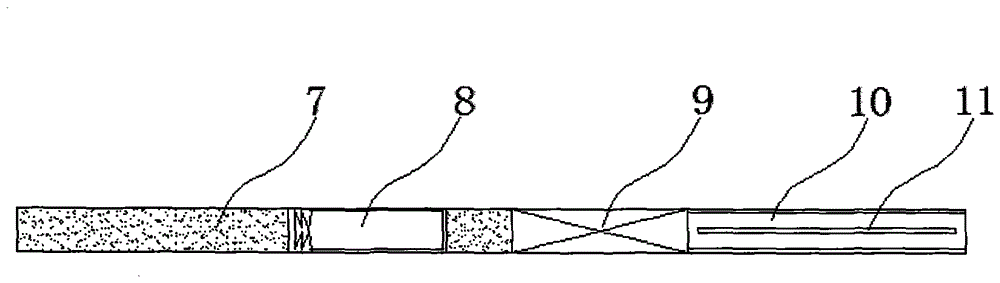

[0021] Three to four pairs of vertical wedge cut holes are arranged in the middle of the tunneling face. Each pair of vertical wedge cut holes includes a mirrored primary cut hole 1 and a secondary cut hole 2 set on both sides. The first-level cut hole 1 is composed of three blast holes arranged side by side, the second-level cut hole 2 is composed of four blast holes arranged side by side, and the middle of the first-level cut hole 1 is provided with 1 ~2 straight holes 3, the hole distance between each two adjacent shot holes in the first-level cut hole 1 is 800-1000mm, and every two adjacent shot holes in the second-level cut hole 2 The hole distance between the holes is 300-400mm. When two straight holes 3 are arranged, the hole distance between the straight holes 3 is 300-500mm, and the distance between the first-level cut holes 1 is 800- 1000mm, the distance between the second-level cut holes 2 is 1200-1400mm, the second-level cut holes 2 adopt a coupled continuous charge...

Embodiment 2

[0025] Three to four pairs of vertical wedge cut holes are arranged in the middle of the tunneling face. Each pair of vertical wedge cut holes includes a mirrored primary cut hole 1 and a secondary cut hole 2 set on both sides. The first-level cut hole 1 is composed of three blast holes arranged side by side, the second-level cut hole 2 is composed of four blast holes arranged side by side, and the middle of the first-level cut hole 1 is provided with 2 Two straight holes 3, the hole distance between each two adjacent blast holes in the first-level cut hole 1 is 800-1000 mm, and each two adjacent blast holes in the second-level cut hole 2 The distance between the holes is 300-400mm, the distance between the straight holes 3 is 300-500mm, the distance between the first-level cut holes 1 is 800-1000mm, and the distance between the second-level cut holes 2 The distance between the two is 1200~1400mm, the second-level cut hole 2 adopts a coupled continuous charge, the straight hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com