Coal mine roadway supporting method and working face hole-cutting anchor mesh ladder and individual supporting device used by same

A coal mine roadway and working face technology, applied in pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of high labor intensity of support for employees, low level of single-level excavation, and complicated support technology, and achieve the improvement of on-site Safe working environment, improved tunneling construction speed, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

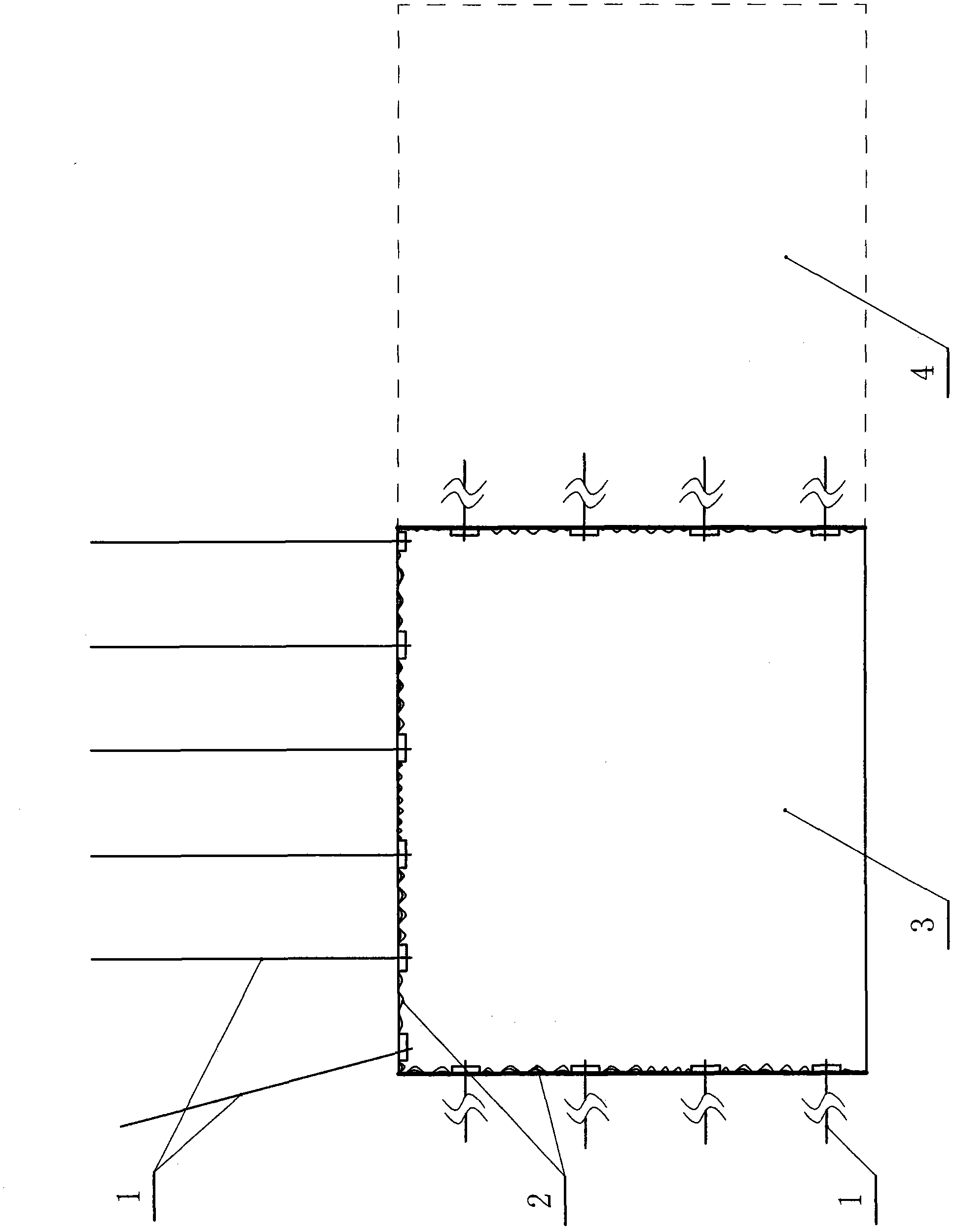

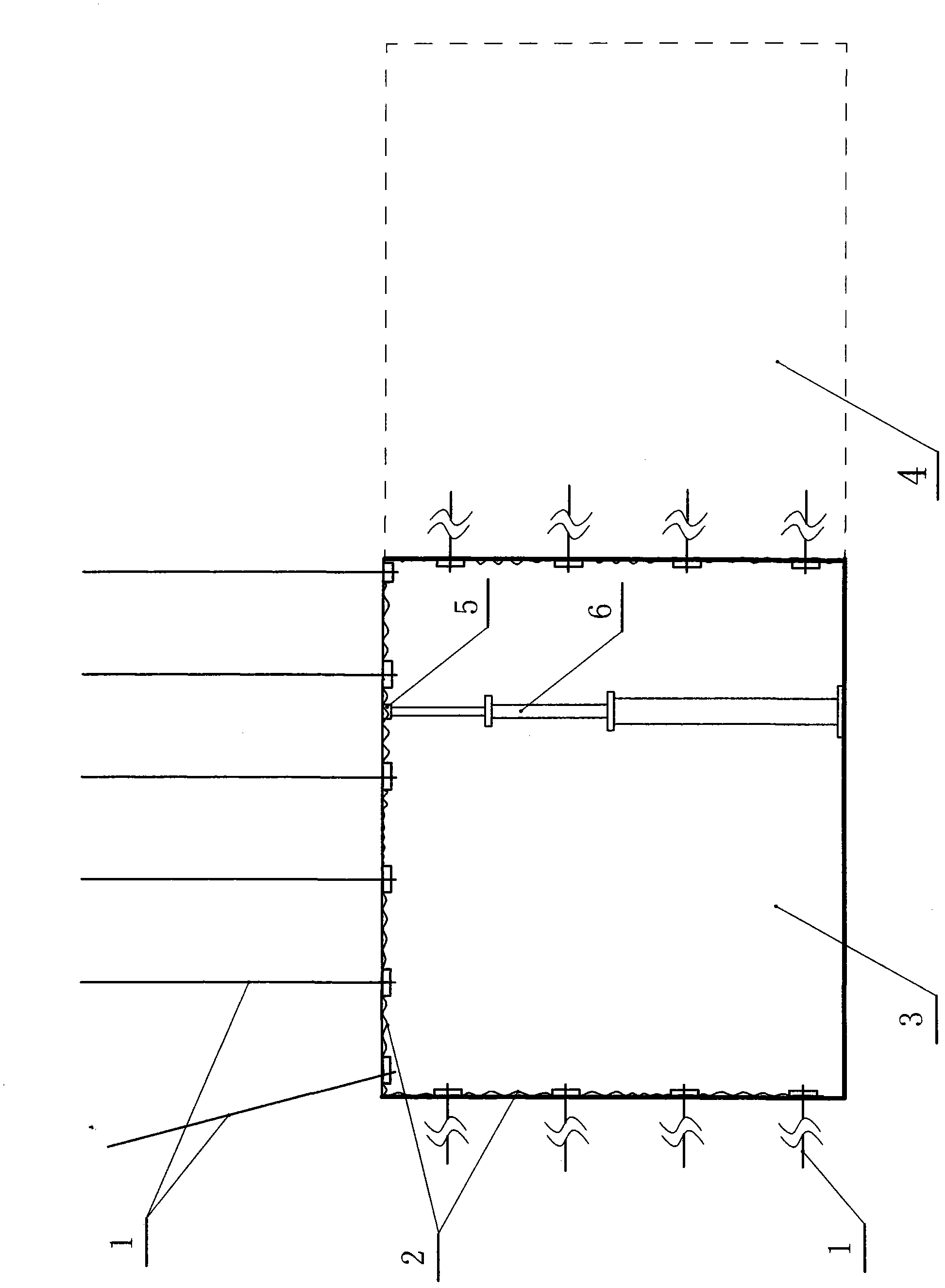

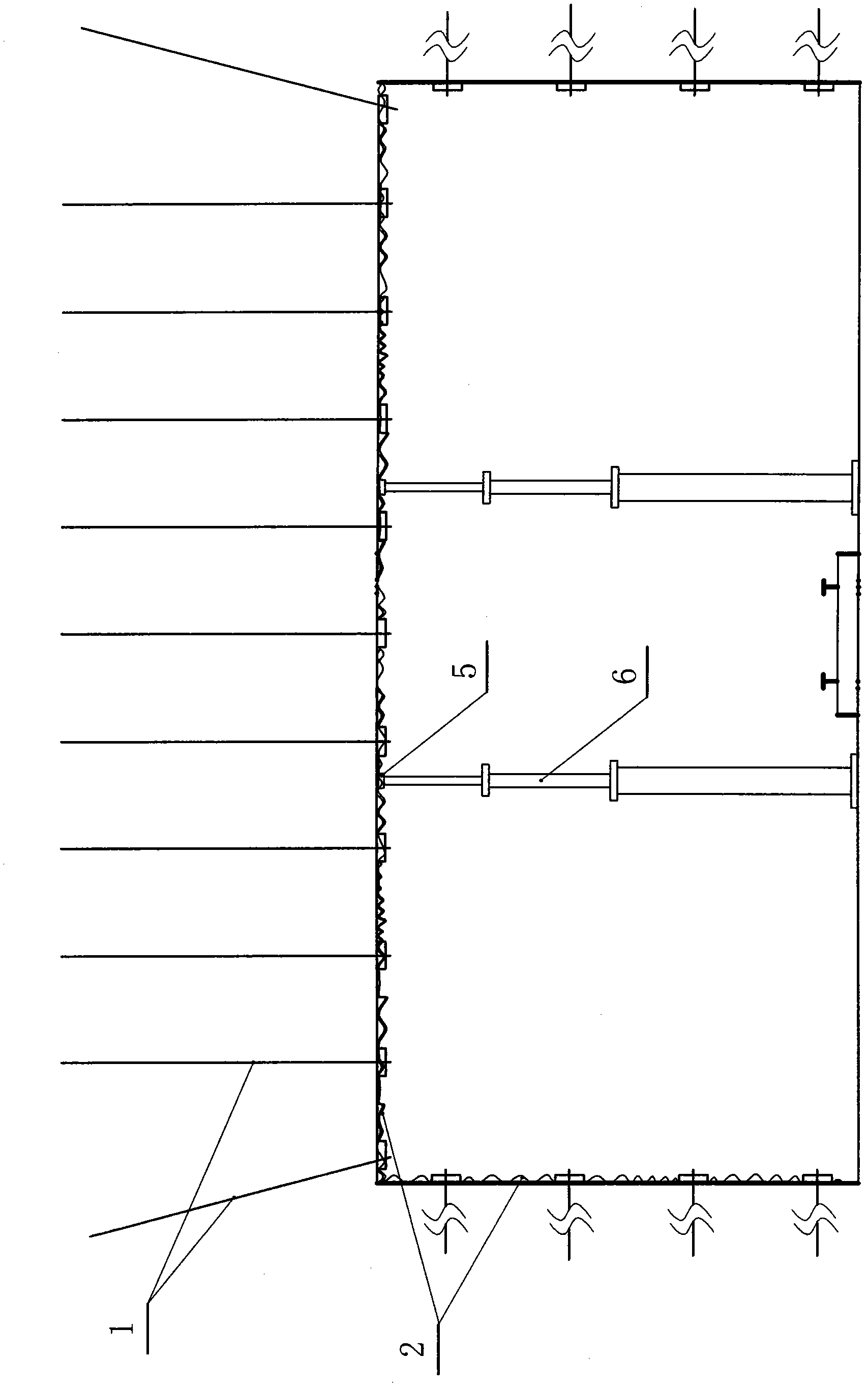

[0020] The present invention as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the construction technique scheme that the present invention adopts is:

[0021] The implementation plan and steps of anchor mesh ladder plus single support in the working face:

[0022] a. The first construction side (width 3.4m--4.2m) of the eye-cutting construction is supported by anchor net ladders;

[0023] b. After the construction on one side is completed, carry out the construction of the eye-cutting brush to the design width; before the eye-cutting brush is large, equip a XRB2B80 / 35 hydraulic pump station in the roadway at the end of the opening of the opening;

[0024] c. A row of single hydraulic props will be supported on the side where the cut eye has been constructed at a distance of 1.2m from the coal wall on the brush side according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com