Cutting blasting method suitable for excavation of high-plastic low-strength rock tunnel

A rock and tunnel technology, which is used in the field of high-plastic and low-strength rock tunnel excavation and cutting and blasting, can solve the problem of high cutting cost, and achieve the effects of reducing the unit consumption of explosives, expanding the free surface, and increasing the volume of the cutting cavity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

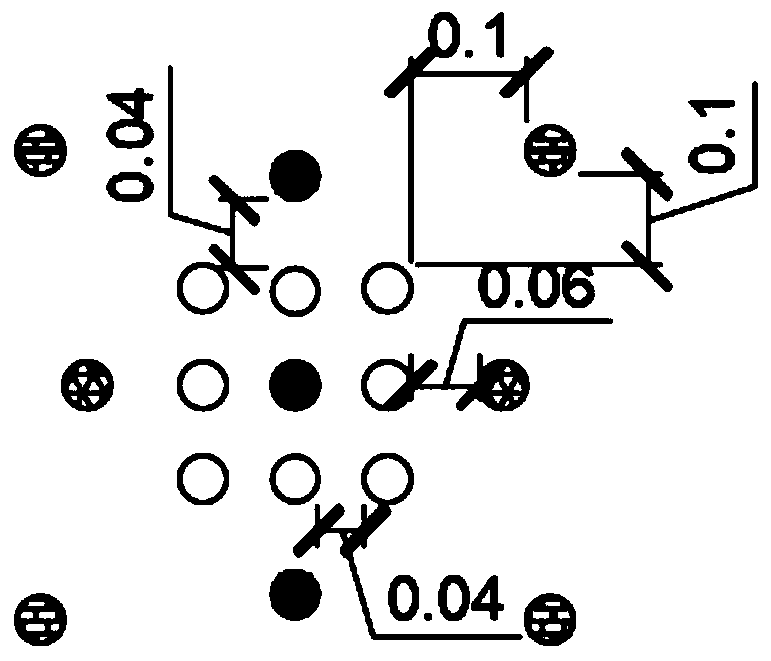

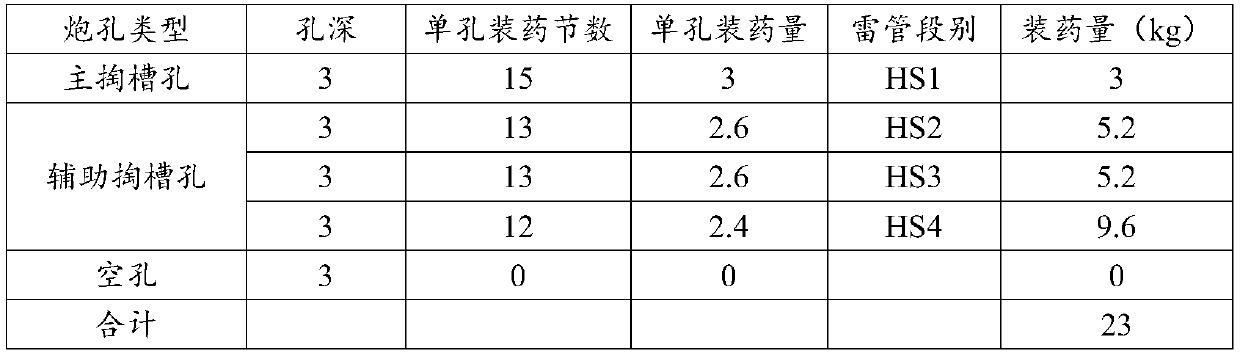

[0048] According to the analysis of the dynamic characteristics of quartz mica schist and the numerical simulation of rock-breaking cracks, the mica-rich schist has obvious plastic characteristics under the action of explosion load, and the explosion stress wave decays very fast and has a particularly large amplitude within 40cm from the blast center. Most of the energy of the stress wave is consumed in the plastic deformation of the rock and the breaking of the rock within 40cm from the blast center, and the rapid energy consumption restricts the further breaking of the rock.

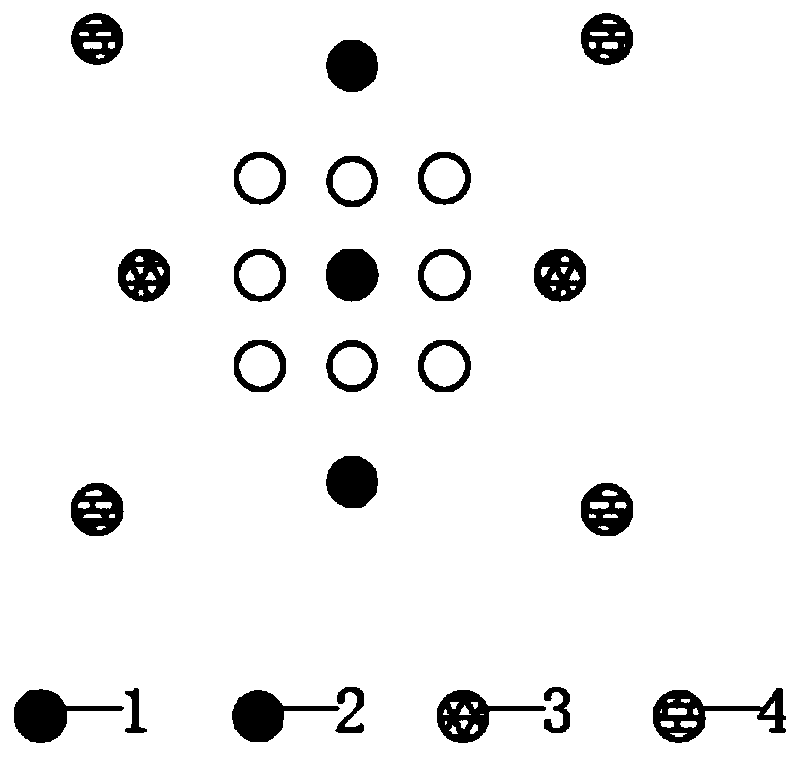

[0049]The basic idea of the present invention is to reduce the distance between the cut holes to ensure that the explosion stress wave energy produced by the explosive is much higher than the energy required for the plastic deformation of the plastic rock mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com