Segmental hydraulic fracturing coal seam pressure releasing device and method

A technology of hydraulic fracturing and pressure relief devices, which is applied in safety devices, earthwork drilling, gas discharge, etc., and can solve problems such as complex processes and multiple applications of ground drilling

Inactive Publication Date: 2012-10-03

CCTEG SHENYANG RES INST

View PDF6 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the complexity of the process, the fracturing equipment weighs tens to hundreds of tons, and cannot be used in the limited space underground.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

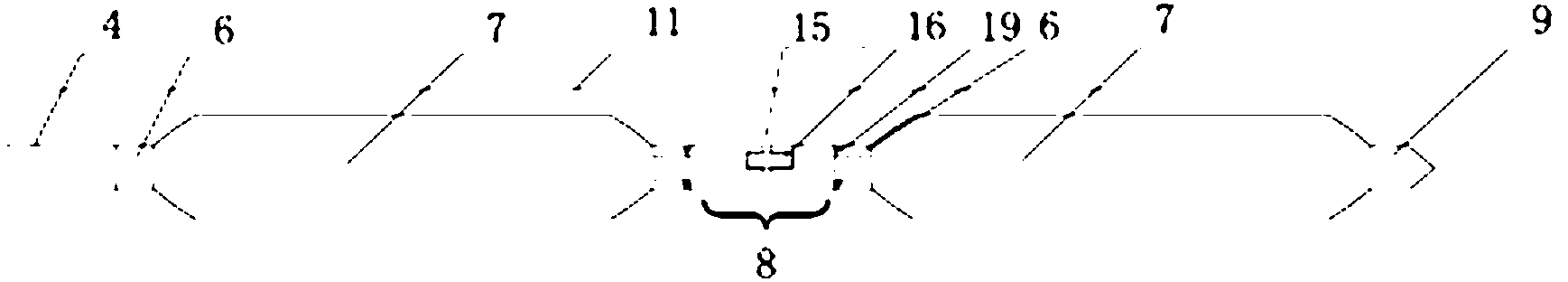

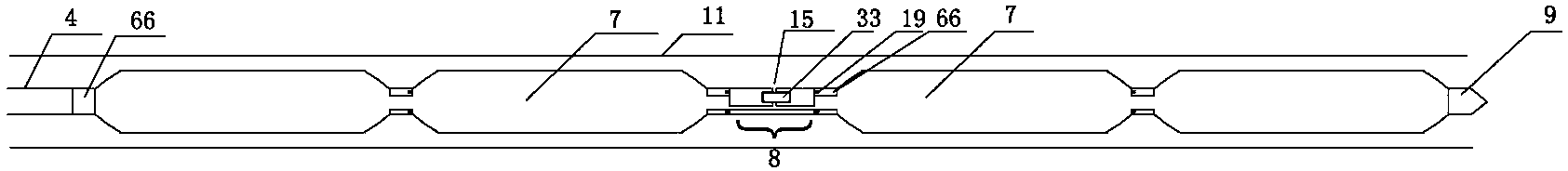

[0026] The shrinkage diameter of the sealing capsule 7 is 40mm-60mm, the expansion diameter is 60-80mm, and the length of the sealing capsule 7 is 1m-2m.

[0027] Example 2:

Embodiment 2

[0029] Example 3:

Embodiment 3

[0031] Example 4:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

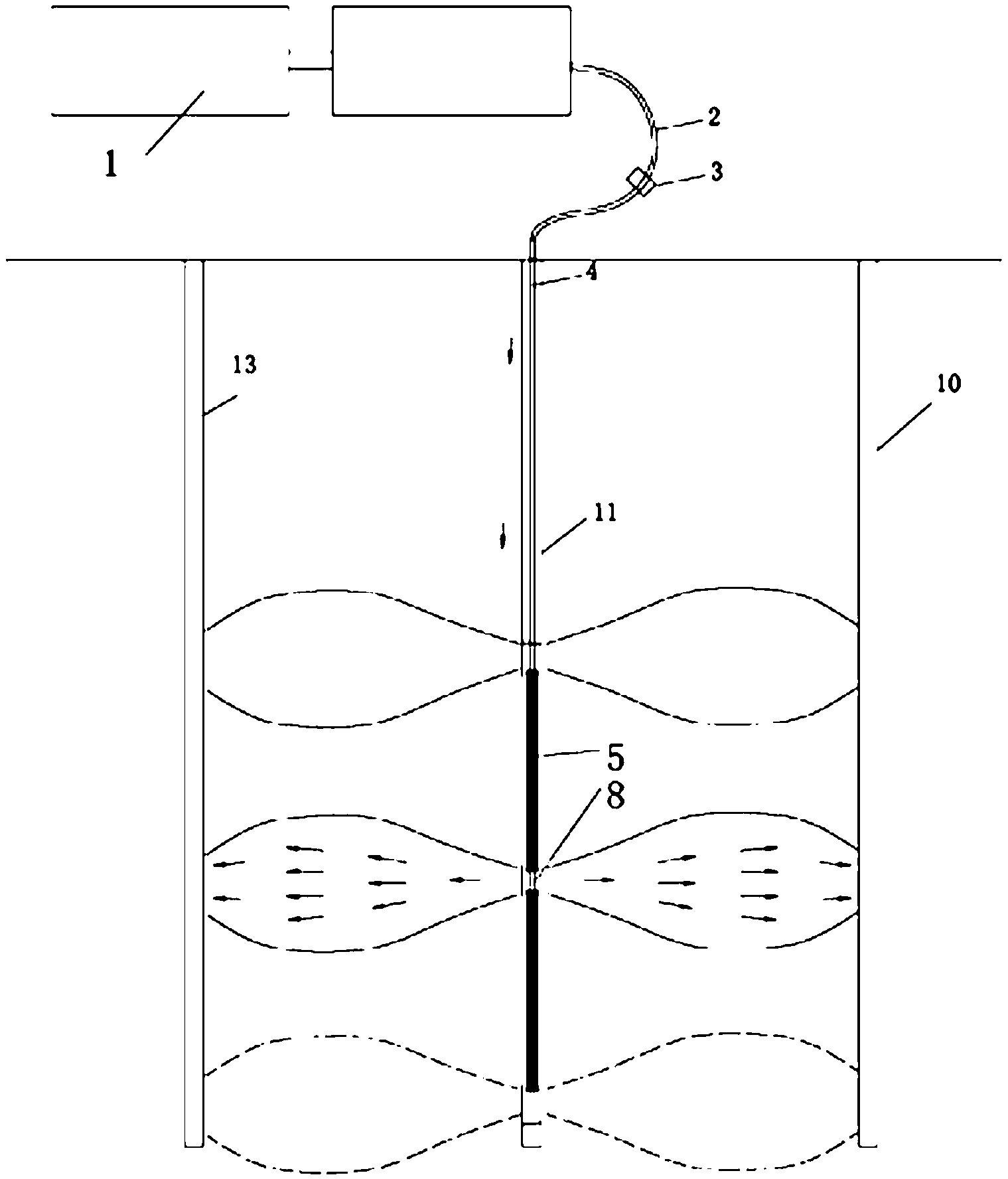

The invention relates to a segmental hydraulic fracturing coal seam pressure releasing device. A high pressure hydraulic pump station is connected to a segmental hydraulic fracturing hole packer through a high pressure hose and a steel push rod; and after the hole packer is fed into a fracturing hole by the push rod, water flows from the high pressure hydraulic pump station to the segmental hydraulic fracturing hole packer through the high pressure hose, flows through a pressure reducing mechanism and is injected into coal for hydraulic fracturing. Water flow also makes hole packing capsules on two sides of a water outlet swell to achieve a sealing effect, and a fracturing range is controlled between the two capsules. Due to the action of the pressure reducing mechanism, the pressure of the hole packing capsules is always greater than that of the water outlet to realize self sealing. During field implementation, a seam hole can be divided into a plurality of segments and is subjected to fracturing segment by segment; meanwhile, a control hole parallel to the fracturing hole is constructed to increase a free face and can drain, bring out coal dust and achieve a hydraulic loosening effect, and the coal between the hydraulic fracturing hole and the control hole is penetrated through pressure finally, so that the coal seam releases pressure fully, the pre-extraction time of the coal seam is shortened and the extraction rate is improved.

Description

technical field [0001] The invention relates to an underground coal seam hydraulic fracturing device and method, in particular to a staged hydraulic fracturing coal seam pressure relief device and a pressure relief method. Background technique [0002] Due to the difficulty of pre-pumping the gas in the high gas and low permeability coal seam, a large amount of gas gushes out during the mining operation of high gas and coal and gas outburst mines, which easily causes the gas in the working face to exceed the limit, and even coal and gas outburst occur ACCIDENT. With the development of high-efficiency and intensive coal production and the continuous increase of mining depth, this problem has increasingly restricted coal mine safety production. In coal and gas outburst mines that do not have protection layer mining conditions, pre-extraction of outburst coal seam gas has become an important regional outburst prevention measure. How to increase the effective range of drilling...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B43/26E21F7/00

Inventor 王魁军富向王宇鹍李江涛张劲松刘文波曲晓明杨宏伟王路军

Owner CCTEG SHENYANG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com