A double-drill full-hydraulic drill type pressure relief device and pressure relief method

A full-hydraulic, dual-bit technology, applied in drilling equipment and methods, drilling equipment, drill pipes, etc., can solve problems such as threatening the life safety of operators, high labor intensity of workers, and poor stability of holes, and reduce workers' labor. Strength, eliminates large coal cannons, has the effect of hole stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

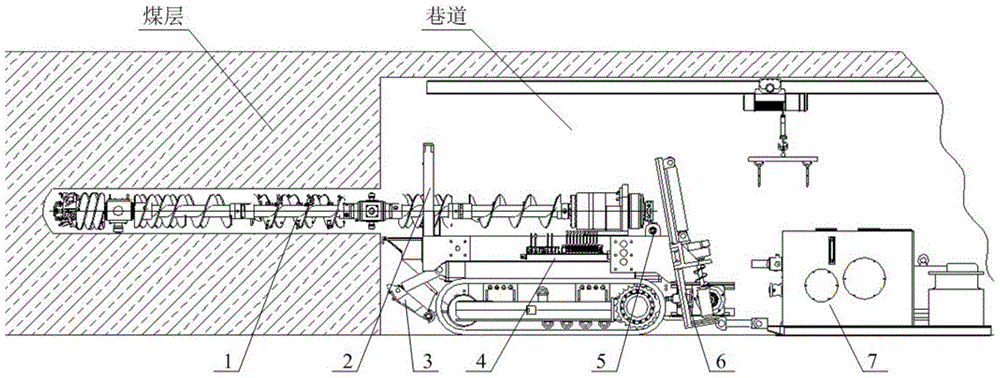

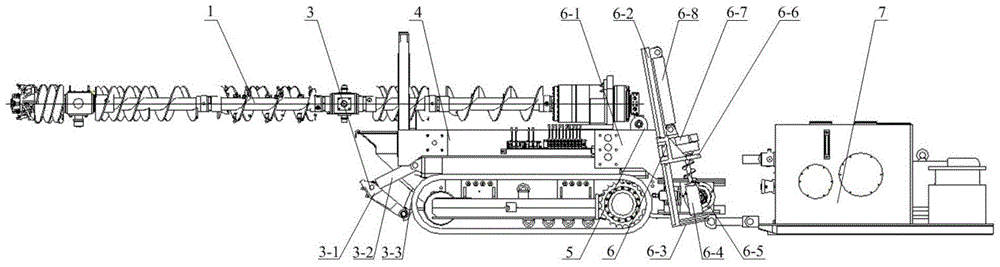

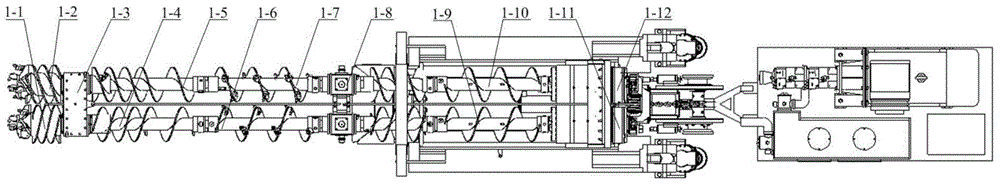

[0033] Such as figure 1 As shown, the double-drill full-hydraulic drilling pressure relief device of the present invention is mainly composed of a drilling tool assembly 1, a claw assembly 2, an inclination adjustment assembly 3, a main engine 4, a cooling assembly 5, a bolt assembly 6, The hydraulic assembly consists of 7, and also includes crawlers, scraper conveyors, and monorail cranes. The crawlers, monorail cranes, and scraper conveyors are used in conjunction with double-drill full-hydraulic drilling pressure relief equipment. Inside the fuselage of hydraulic drilling pressure relief equipment, the monorail crane is located directly above the fuselage. The claw assembly 2 is fixed on the front of the main machine 4 through a pin shaft, the tilt adjustment assembly 3 is symmetrically arranged at the lower part of the claw assembly 2, and the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com