Deep well filling pressure release pipeline device and method

A technology for pressure relief pipelines and deep wells, which is applied in mining equipment, fillings, earthwork drilling, etc., can solve the problems of energy waste and wasteful energy, etc., and achieve the effect of improving efficiency, sufficient pressure relief, and high energy utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

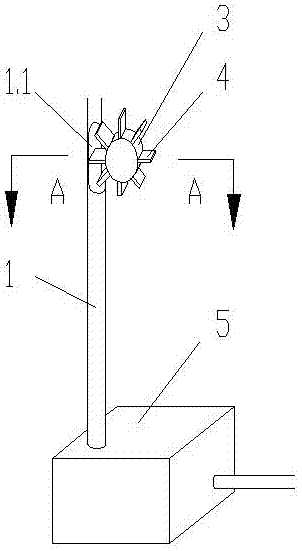

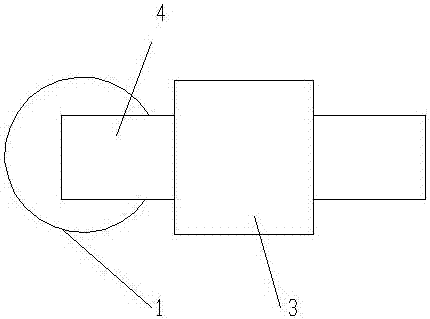

[0046] refer to figure 1 and 2 , a deep well filling pressure relief pipeline equipment, including a pipeline 1 and a pressure relief pool 5, the top of the pressure relief pool 5 is connected to the pipeline 1, and the tail is connected to another section of the pipeline 1, the side of the pipeline 1 is provided with an opening 1.1, and the opening 1.1 is provided Potential energy conversion device 2 is arranged.

[0047] The potential energy conversion device 2 includes a main shaft 3 and a ring of baffles 4 around the main shaft 3; the baffles 4 extend into the opening 1.1.

[0048] When the baffle plate 4 is horizontal, the cross-sectional area of the part extending into the opening 1.1 is 1 / 2 of the cross-sectional area of the pipeline 1.

[0049] The lower diameter of the opening 1.1 on the side of the pipeline 1 is larger than the upper diameter.

[0050] The volume of the pressure relief pool is not less than 10 cubic meters.

[0051] The working principle of t...

Embodiment 2

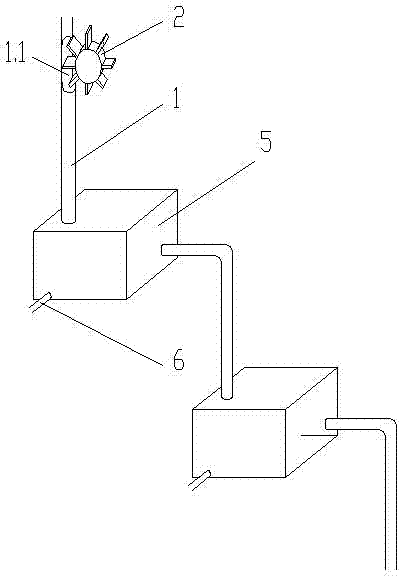

[0058] refer to image 3 and 4 , Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is:

[0059] The deep well filling pressure relief equipment provided by this embodiment includes two pressure relief pools 5, and also includes a pressure relief pool 5, the top of the pressure relief pool 5 is connected to the pipeline 1, and the tail is connected to the next section of the pipeline 1. The volume of the pressure relief pool 5 is greater than 10 cubic meters, the levels of the two pressure relief pools 5 are successively reduced.

[0060] A disturbance device is provided in the pressure relief pool 5 .

[0061] The disturbing device is a compressed air nozzle 6.1 installed at the bottom of the pressure relief pool 5, and the compressed air nozzle 6.1 is arranged on the air injection pipe 6, and the air injection pipe 6 extends from one side of the pressure relief pool 5.

[0062] The working principle of this embodiment is:

[0063]...

Embodiment 3

[0066] With reference to 5 and 6, embodiment 3 of the present invention is basically the same as embodiment 1, the difference is:

[0067] A disturbance device is provided in the pressure relief pool 5 .

[0068] The disturbance device is a stirring paddle 7, and the auxiliary shaft 8 extends from the top of the pressure relief pool 5, and the stirring paddle 7 is arranged at the bottom of the auxiliary shaft 8; one end of the main shaft 3 of the potential energy conversion device 2 is coaxially connected with a main bevel gear 9, the main cone The bevel gear 9 meshes with the secondary bevel gear 10, and the secondary bevel gear 10 is sleeved with the secondary shaft 8 at the center.

[0069] The working principle of this embodiment is:

[0070] The slurry falls from the pipeline 1, touches the baffle 4 on the way, and receives the resistance from the baffle 4 to achieve the effect of increasing resistance and energy dissipation; during this process, the kinetic energy of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com