Mechanical rock breaking method for coal mine rock roadway

A rock roadway and rock breaking technology, which is applied in the field of mechanical rock breaking in coal mine rock roadways, can solve the problems of difficult removal of gun smoke, difficult crushing, and low operating efficiency, so as to reduce the difficulty of rock breaking by impact, save manpower and material resources, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

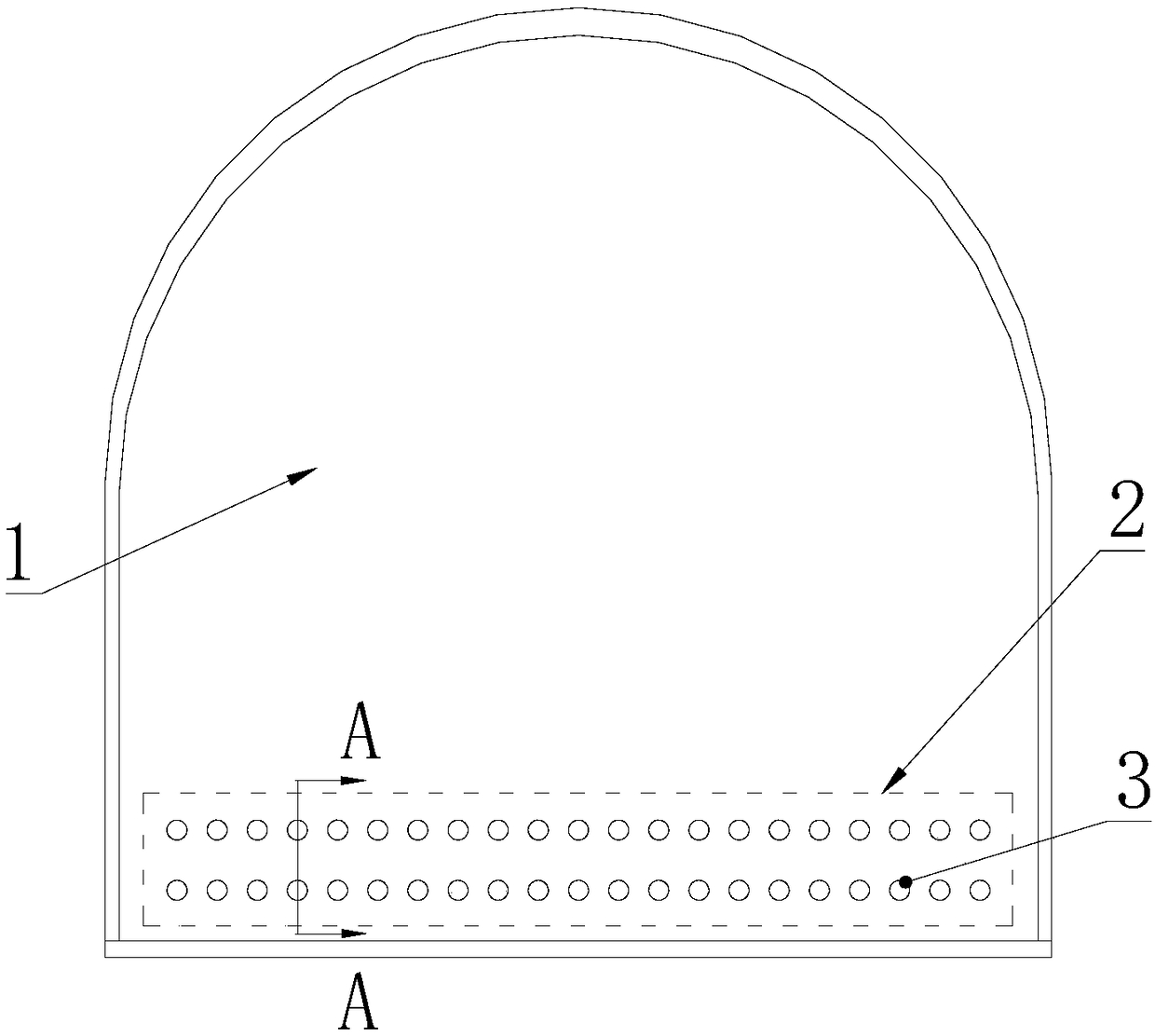

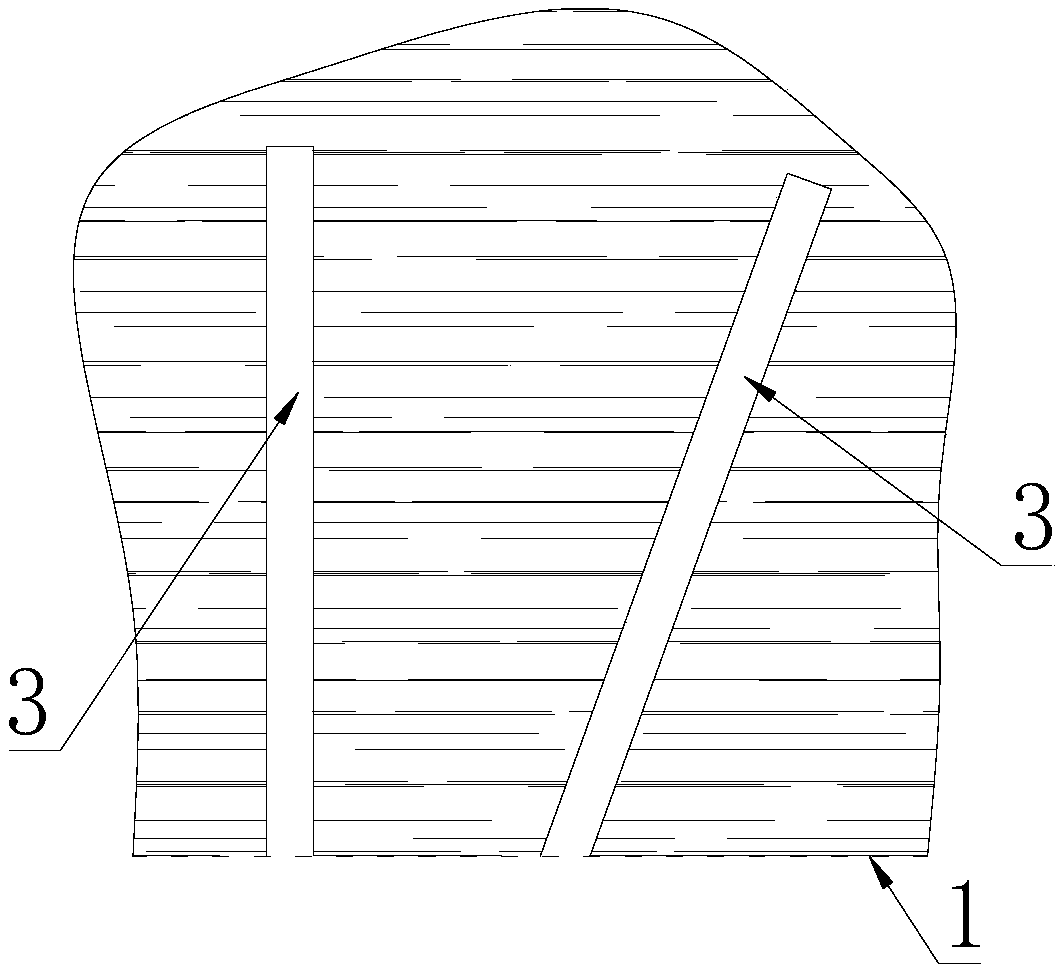

[0044] On the basis of the foregoing, in this embodiment, as figure 2As shown, the holes 3 in the drilling area 2 are distributed in rows, and the distance between adjacent holes 3 in the same row is 3-5 times the diameter of the holes 3 . According to the depth of the hole 3 and the hardness of the rock, if the distance between the holes 3 is selected, the crack at one impact point can extend to multiple holes 3 at the same time, thereby reducing the impact point of the breaking hammer and improving the rock breaking efficiency in the drilling area 2 . In this way, when the two sides of the opening 3 are impacted, the rocks around the opening 3 begin to break, thereby forming a long depression in the area where the entire row of openings 3 is located, which is convenient for further rock-breaking operations in the later stage.

[0045] Optionally, the holes 3 in the drilling area 2 are arranged in multiple rows, and the distance between the holes 3 in two adjacent rows is 1-...

Embodiment 2

[0049] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the openings 3 in the drilling area 2 are set in one circle or multiple circles nested in each other, and the openings 3 are adjacent in the same circle. The pitch is 3-5 times of the diameter of the opening 3 . This kind of implementation is generally arranged on one side or the middle of the palm surface 1, and a circle of openings 3 is set, and the inner and outer sides of the circle are respectively impacted. The crack can extend from the impact point to the nearby opening 3, thereby closing the opening. 3 The rocks on both sides were broken to form a ring-shaped depression, and then excavated to the inside and outside respectively. The spacing of the openings 3 in the same circle can also be flexibly selected. If the distance between the openings 3 is too close, the openings 3 will be wasted. If the distance between the openings 3 is too far, more impact ...

Embodiment 3

[0052] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1 or Embodiment 2, the only difference is that the drilling area 2 is in the middle of the face 1, and the openings 3 in the drilling area 2 are arranged at intervals along the same helical line , the distance between adjacent holes 3 distributed along the helix is 3-5 times the diameter of the holes 3 . When crushing, it can be impacted along a certain distance on both sides of the helix. The distance of the opening 3 is 3-5 times the diameter of the opening 3. Within this range, a crack at one impact point can extend to two adjacent openings at the same time. 3. The efficiency of rock breaking is high; a depression is formed along the spiral line, and the rock between the spiral lines is cleaned to form a complete circular depression area, which is then used as the center to advance around.

[0053] In some embodiments, the distance between two adjacent turns of the helix is 1-3 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com