Diamond bit used for engineering investigation and its making method

A technology of diamond drill bit and engineering survey, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., which can solve the problems of unsatisfactory drill bit diameter protection effect, reduced service life, and single structure, so as to achieve improved effect, improved efficiency, and reduced contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

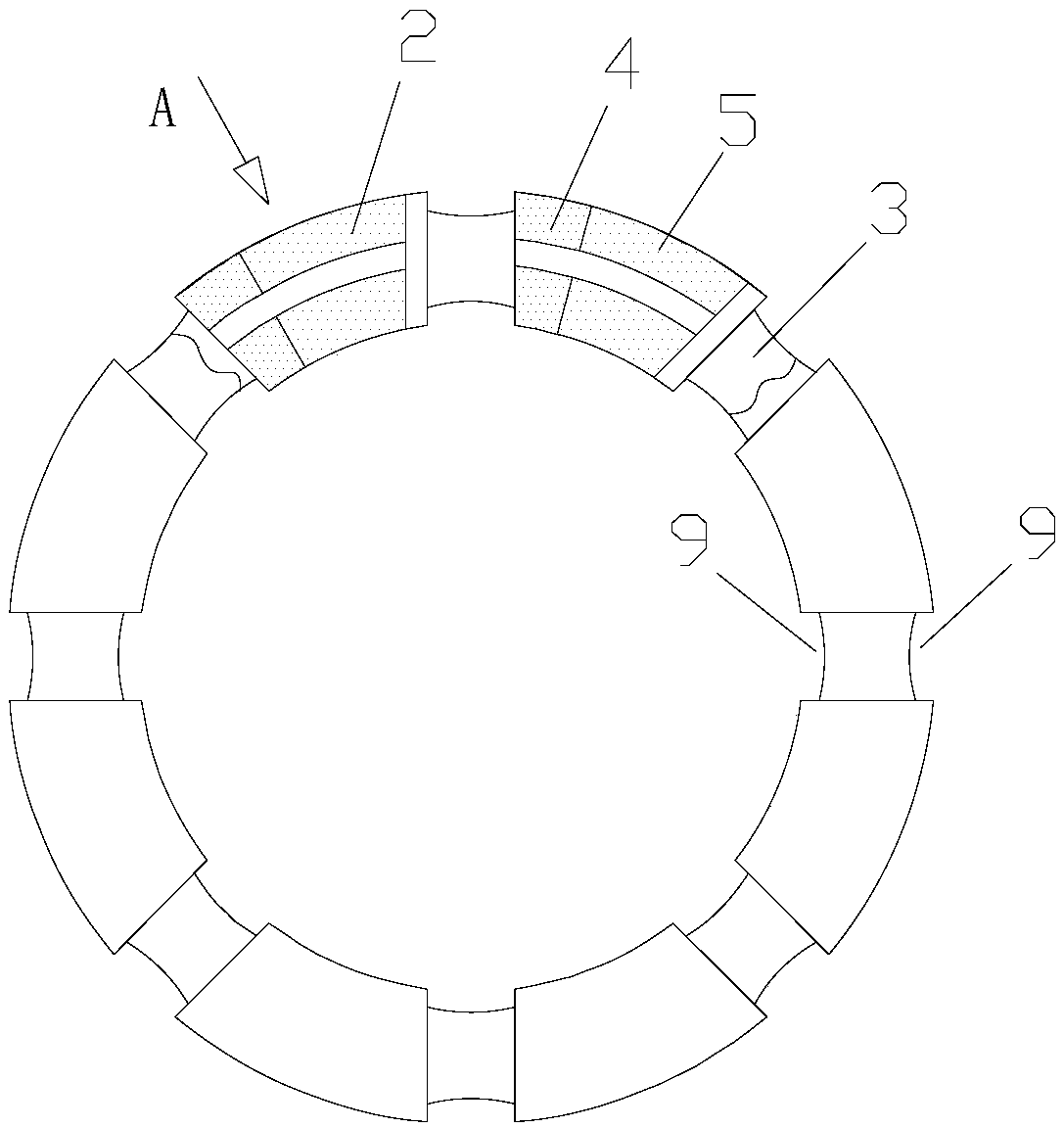

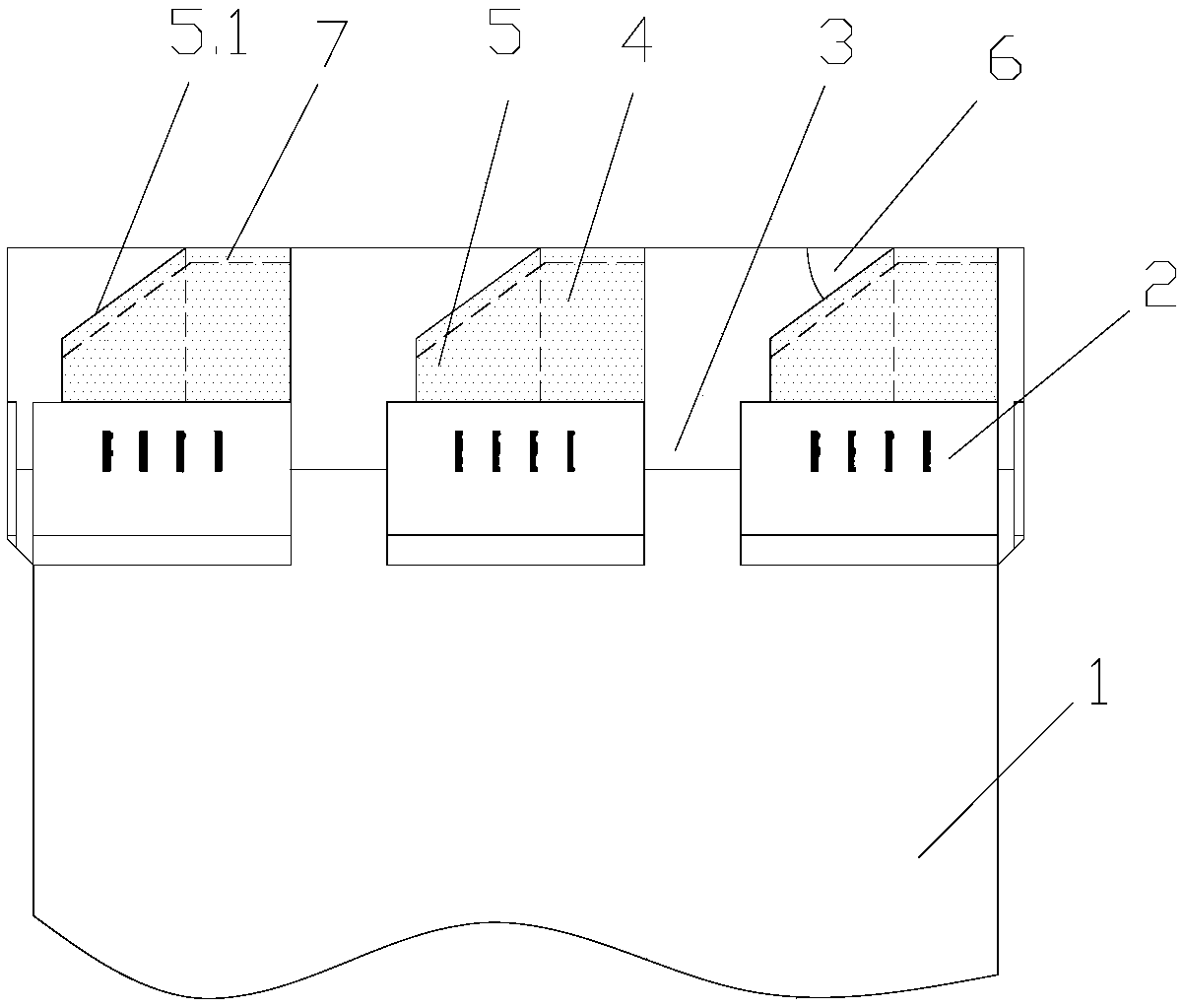

[0028] Such as figure 1 , figure 2 A diamond drill bit for engineering survey shown includes a drill steel body 1 and fan-shaped cutting teeth 2 arranged at the front end of the drill bit steel body 1. A nozzle 3 is arranged between adjacent two fan-shaped cutter teeth 2. The number of nozzles is Eight, the width of each nozzle is 6.5mm, and the depth of 9 inner and outer water tanks is 1.5mm;

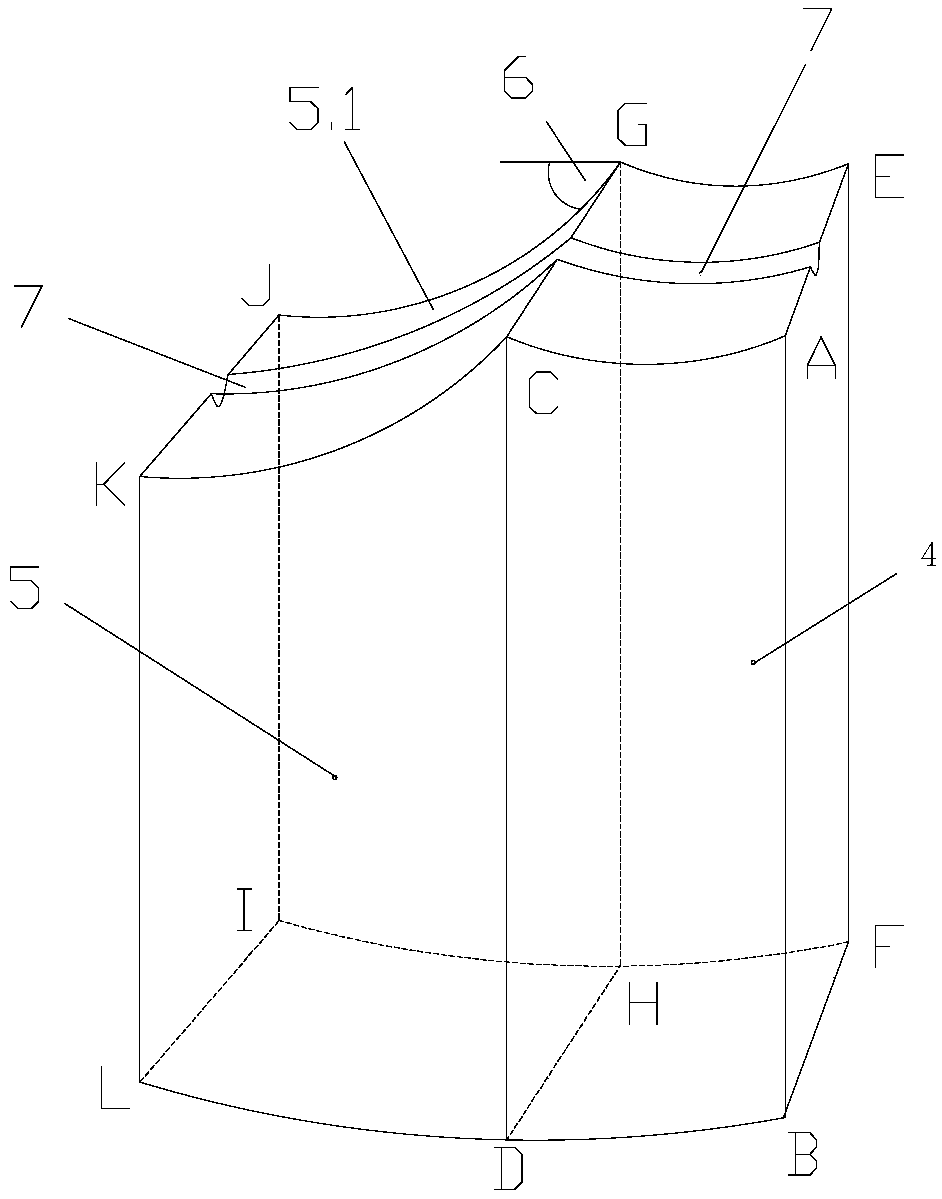

[0029] Such as image 3 As shown, the fan-shaped cutter 2 is composed of a fan-shaped cylindrical cutter 4 and a fan-shaped trapezoidal cutter 5, image 3 The fan-shaped cylindrical cutting teeth in 4 ( image 3 The polyhedron ABDCGEFH in the composition), the fan-shaped trapezoidal cutting tooth 5 (polyhedron CDLKJIHG is formed); the front cutting surface 5.1 of the sector-shaped trapezoidal cutting tooth 5 is a slope surface (consisting of the surface CKJG); the sector-shaped cutting tooth 2 is provided with a drill ring groove 7. The drill groove is 2mm deep and 2.5mm wide. Th...

Embodiment 2

[0037] A diamond drill bit for engineering investigation, comprising a steel body 1 of the drill bit and fan-shaped cutting teeth 2 arranged at the front end of the steel body 1 of the drill bit, and nozzles 3 are arranged between two adjacent fan-shaped cutting teeth 2, and the number of nozzles is seven. Each nozzle is 5mm wide, and the inner and outer water tanks 9 are each 1.5mm deep;

[0038] Such as image 3As shown, the fan-shaped cutter 2 is composed of a fan-shaped cylindrical cutter 4 and a fan-shaped trapezoidal cutter 5, image 3 The fan-shaped cylindrical cutting teeth in 4 ( image 3 The polyhedron ABDCGEFH in the composition), the fan-shaped trapezoidal cutting tooth 5 (polyhedron CDLKJIHG is formed); the front cutting surface 5.1 of the sector-shaped trapezoidal cutting tooth 5 is a slope surface (consisting of the surface CKJG); the sector-shaped cutting tooth 2 is provided with a drill ring groove 7. The drill groove is 2mm deep and 2mm wide. The projected...

Embodiment 3

[0046] A diamond drill bit for engineering investigation, comprising a drill steel body 1 and fan-shaped cutting teeth 2 arranged at the front end of the drill bit steel body 1, nozzles 3 are arranged between two adjacent fan-shaped cutting teeth 2, and the number of nozzles is eight 1, the width of each nozzle is 7mm, and the depth of the inner and outer water tanks is 1.5mm;

[0047] Such as image 3 As shown, the fan-shaped cutter 2 is composed of a fan-shaped cylindrical cutter 4 and a fan-shaped trapezoidal cutter 5, image 3 The fan-shaped cylindrical cutting teeth in 4 ( image 3 The polyhedron ABDCGEFH in the composition), sector trapezoidal cutting tooth 5 (polyhedron CDLKJIHG composition); the front end cutting surface 5.1 of sector trapezoidal cutting tooth 5 is a slope surface (consisting of surface CKJG); sector cutting tooth 2 is provided with two drill bit annular grooves 7. The drill groove is 2mm deep and 2.2mm wide. The projected area ratio of the bottom l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com