Method and device for producing glass article from glass melt

A glass melt and glass product technology, applied in glass manufacturing equipment, glass production, glass furnace equipment, etc., can solve the problems of undesired changes in viscosity and density, inability to dissolve and stir, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

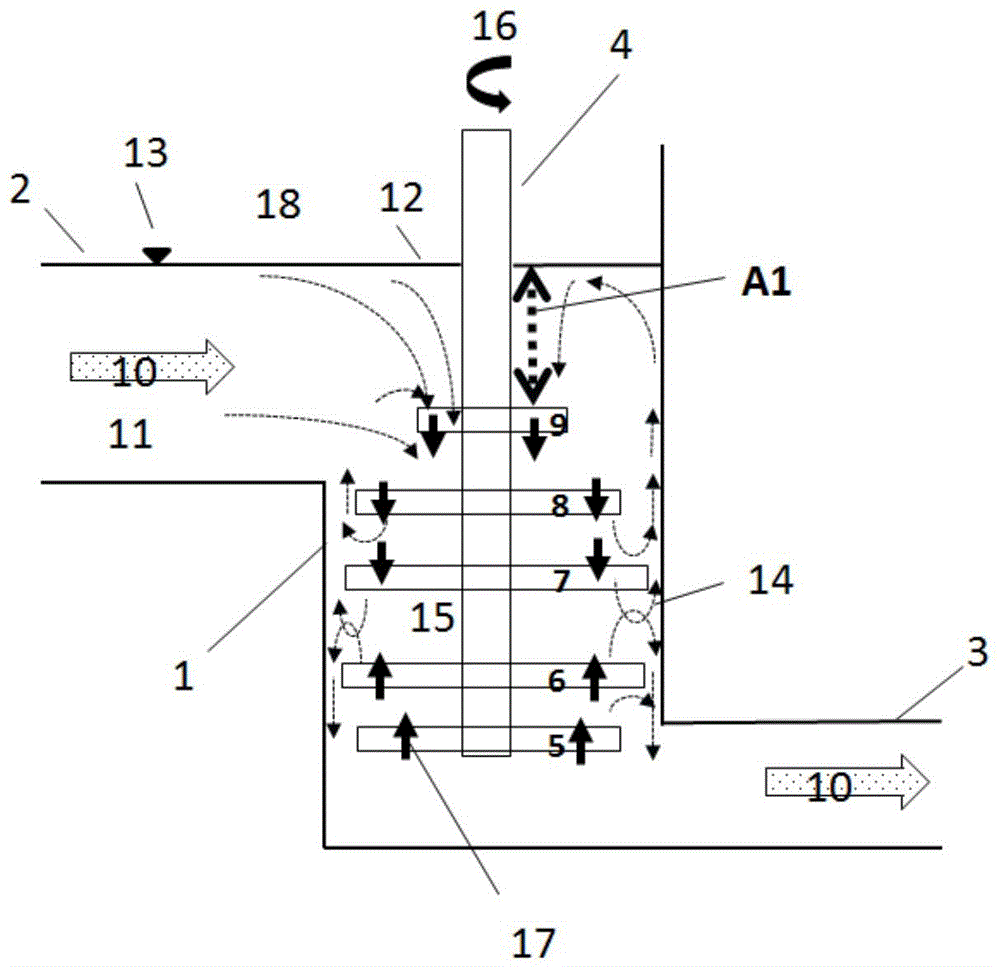

[0171] Methods 1 and 2 and devices 1 and 2 according to the invention are explained in more detail by using the following examples.

[0172] 1. Device 1 and Method 1:

[0173] Continuous pull-in of glass surfaces confirmed by physical simulations is achieved by,

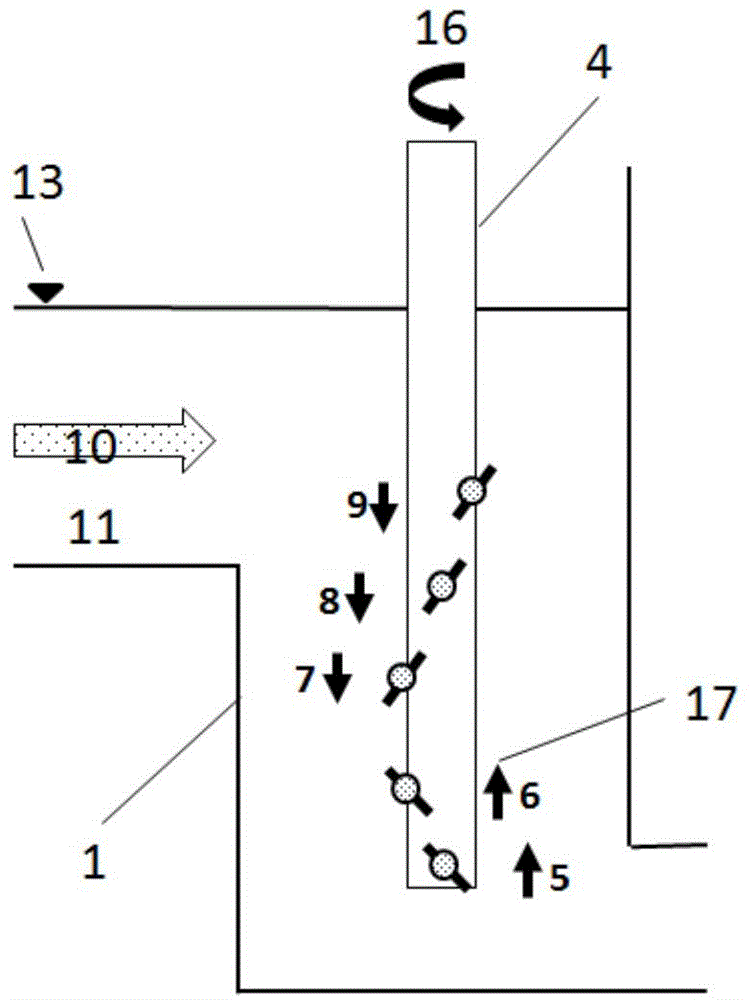

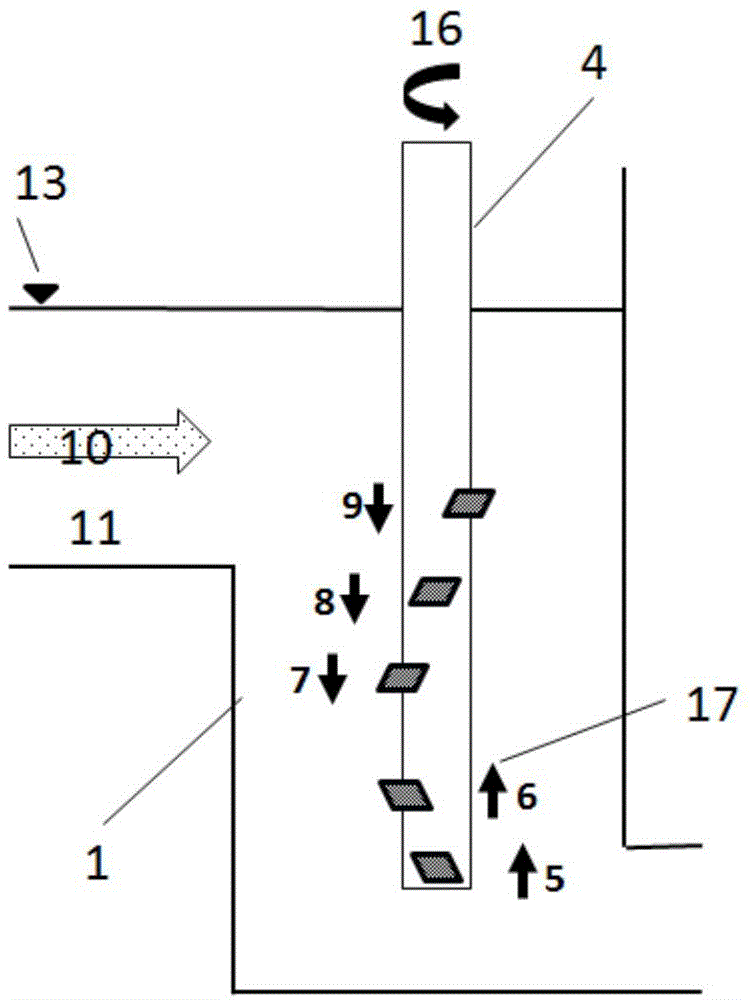

[0174] -5 beater blades,

[0175] - all agitator blades with conveying action,

[0176] - the three upper stirrer blades are each arranged offset by 10° on the stirrer shaft and conveyed downwards,

[0177] - the downward conveying is assisted by the geometry of the stirrer blades,

[0178] - the lower two stirrer blades convey upwards, arranged offset by -10°,

[0179] - the upward conveying is assisted by the geometry of the stirrer blades,

[0180] - The stirrer blades on the stirring shaft are equally spaced between the upper three downwardly conveying stirrer blades,

[0181] - The stirrer blades on the stirring shaft are equally spaced between the lower two upwardly conveying stirrer blades,

[0182] - the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com