A Blasting Method for Reducing Harmful Effects Based on Wave Catch-Energy Dissipation

A wave blocking and effect technology, applied in the field of mining construction, can solve the problems of reducing the stability of surrounding rocks and destroying surrounding structures, and achieve the effect of improving protection and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

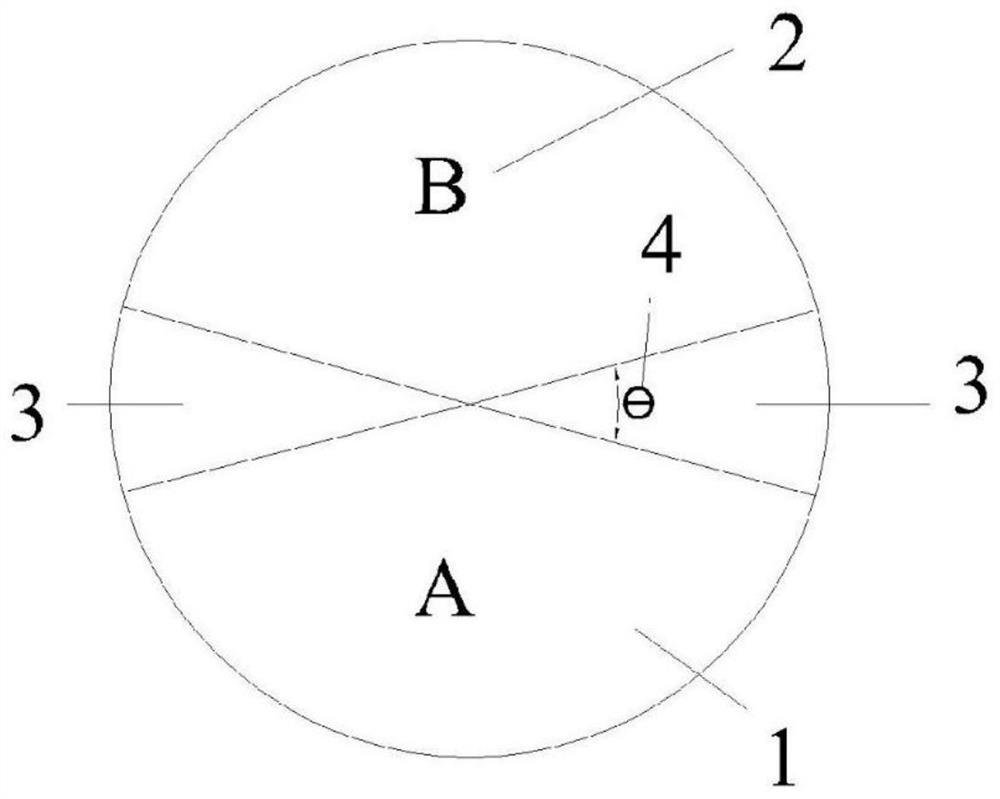

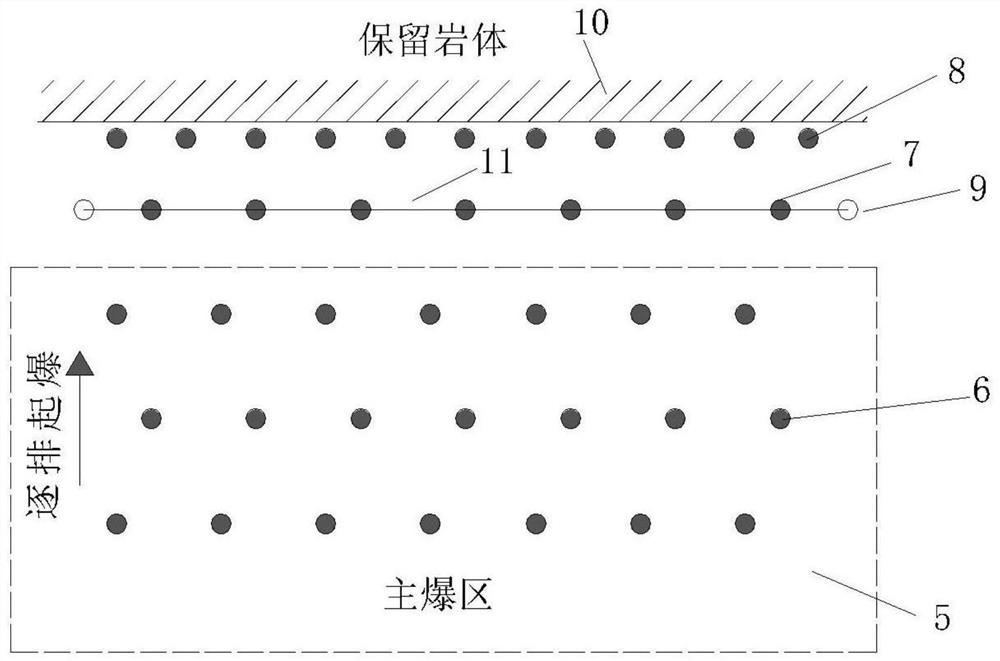

[0045] figure 1 A structural diagram of the energy-gathering-energy-dissipating blaster is given, including cavity A1 for explosives, cavity B2 for explosives or energy-absorbing substances, energy-gathering chamber 3 for water or energy-absorbing substances, and the optimal energy-gathering angle of 15 ° ~ 45 ° gathering angle 4. figure 2 A schematic diagram of the blast hole layout is given, including the main blast area 5, the main blast area blast hole 6, the wave trap hole 7, the energy dissipation hole 8, the empty hole 9, the retained rock mass 10, and the directional fracture 11.

Embodiment 2

[0047] The following description is based on the wave choke-energy dissipation method of reducing the harmful effect blasting method based on embodiment 1, comprising the following steps:

[0048] Step 1: Arranging blastholes 6 in the main explosion zone, such as figure 2 shown.

[0049] As a preferred solution, vertical drilling, the hole depth is 13m, the diameter of the blast hole 6 is 120mm, the distance between the blast hole 6 is 5m, and the row spacing is 4.3m.

[0050] Step 2: Arrange the choke holes 7, the row distance between the choke holes 7 and the energy dissipation holes 8 is 0.75 times the row distance of the blast hole 6 in the main blast zone, and the hole depth is 1.1 times that of the blast hole 6 in the main blast zone, as figure 2 shown.

[0051] As a preferred solution, vertical drilling, hole depth 14.5m, blast hole 7 diameter 120mm, blast hole 7 spacing 5m, choke hole 7 and the blast hole row spacing in the main blast area adjacent to it 4.3m, chok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com