Method for hard roof advanced precracking control caving in coal mine stope

A hard roof and stope technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of difficult charging, potential safety hazards, and few on-site applications, so as to achieve hard roof control, easy operation, scientifically controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

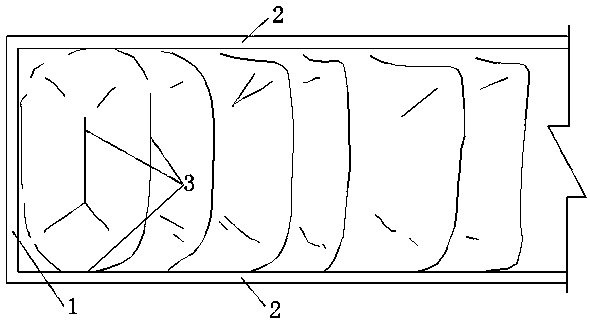

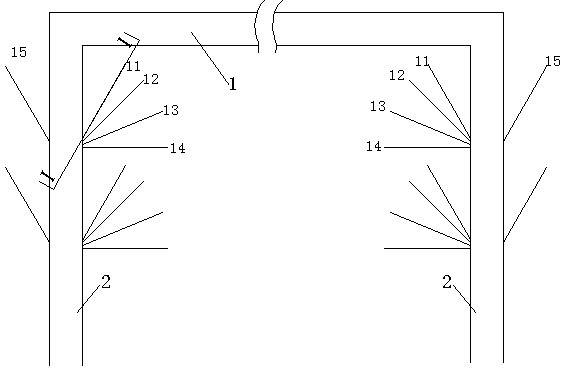

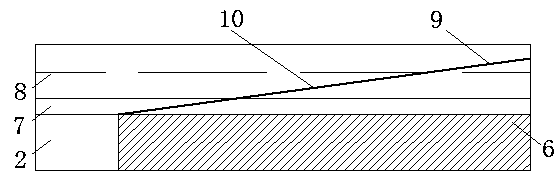

Method used

Image

Examples

Embodiment 1

[0036] Taking Shanxi Coal Transportation and Marketing Group Yuxing Coal Industry Co., Ltd. as an example, the direct top of No. 15 coal seam is K 2 Limestone, K. 2 Limestone is 5.40-7.80m thick, with an average thickness of 6.78m. It is dense and hard, and the lower part is often sandwiched with thin mudstone. This layer is particularly stable in the well field, with an average unidirectional compressive strength of 98.5MPa and an average uniaxial tensile strength of 11.2MPa. Hard and difficult to take off the roof board. The length of the 15101 working face of this mine is 150m, and the mining height is 4.49m, and the cycle progress is 0.8m. The working face adopts four-column support shielding bracket, the bracket is designed with a rated working resistance of 5900kN / frame, and the top control distance of the bracket is 4.5m. Among them, the relationship between the drilling length and the working face length is shown in Table 1.

[0037]

[0038] A method for advance...

Embodiment 2

[0052] The length of the working face is 160m, the mining height is 4.0m, the cycle progress is 0.6m, and the others are the same as in the first embodiment.

Embodiment 3

[0054] The length of the working face is 180m, the mining height is 3.8m, the cycle progress is 0.8m, and the others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com