Sectional type slotting method

A segmented, grooved surface technology, applied in blasting and other directions, can solve the problems of high utilization rate of blastholes, small number of blastholes, clamping of blasthole blasting, etc., and achieve the effect of improving the cutting conditions and increasing the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

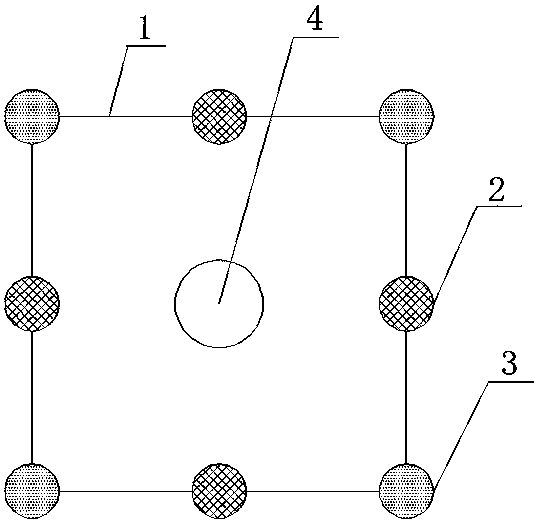

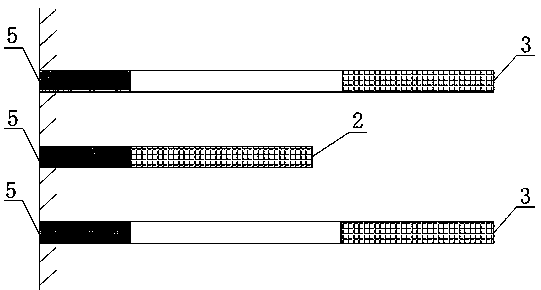

[0019] Such as figure 1 and figure 2 A segmented cutting method shown includes the following steps:

[0020] A square cutout area 1 is set on the tunnel cutout surface, a first set of blastholes 2 are respectively set at the midpoints of the four sides of the square cutout area 1, and a second set of blastholes 3 are respectively set on the four corners of the square cutout area 1, and A compensation hole 4 is set at the center of the square cutting area 1; charges are charged at the bottom of the first group of blastholes 1 and the second group of blastholes 2, and the openings of the blastholes are blocked. The charge length of the first group of blastholes 2 is 1.2m, and the second The charge length of the group of blastholes 3 is 1m, and the plugging length of the holes 5 of the first group of blastholes 2 and the second group of blastholes 3 is 0.6m; the first group of blastholes 1 is detonated first, and the second group of blastholes 2 is delayed by 50ms.

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com