Coalbed drilling hole inside directional dissevering method

An internal orientation and coal seam technology, applied in safety devices, earthwork drilling, wellbore/well components, etc., can solve the problem of increasing the permeability of coal walls, the roof and floor cannot be sealed and drained, and the coal seam water injection area is large, etc. problems, to achieve the effects of not damaging the sealing effect, promoting the amount of gas gushing out, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

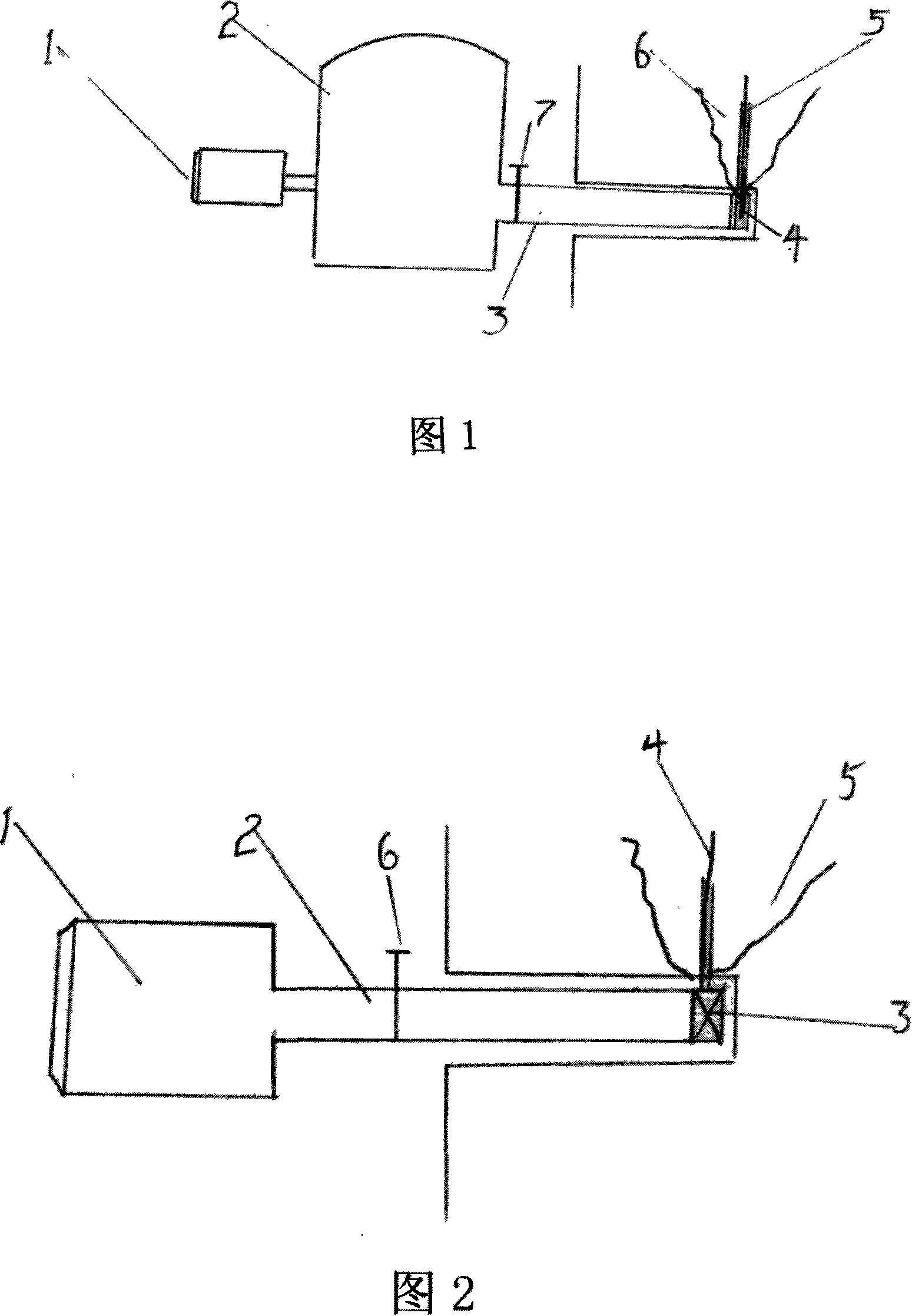

[0017] Now take accompanying drawing 1 as an example: put the drilled high-pressure pipe (3) with the end cut hole (4) into the final hole position of the drilled hole, then open the valve (7), and the high-pressure liquid (5) will rush to the The hole wall of the borehole is directionally split to form cracks (6), and the high-pressure pipeline is controlled to rotate and move, and the end cut hole (4) is also rotated and moved together, thereby realizing the directional split device inside the coal seam borehole.

[0018] Now take accompanying drawing 2 as an example: put the drilled high-pressure pipe (2) with the end cut hole (3) into the final hole position of the drilled hole, then open the valve (6), and the high-pressure liquid (4) will rush to the The hole wall of the borehole is directionally split to form a crack (5), and the high-pressure pipeline is controlled to rotate and move, and the end cut hole (3) is also rotated and moved together, thereby realizing the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com