Segment pre-blasting technology for steeply dipping hard coal seam roof

A technology with a hard roof and a large inclination angle, which is applied in blasting, roof beams supporting mine roofs, mining equipment, etc., can solve problems such as uneven damage, reduce caving steps, ensure relative stability, and lower supports Effects of loads and dynamic load factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

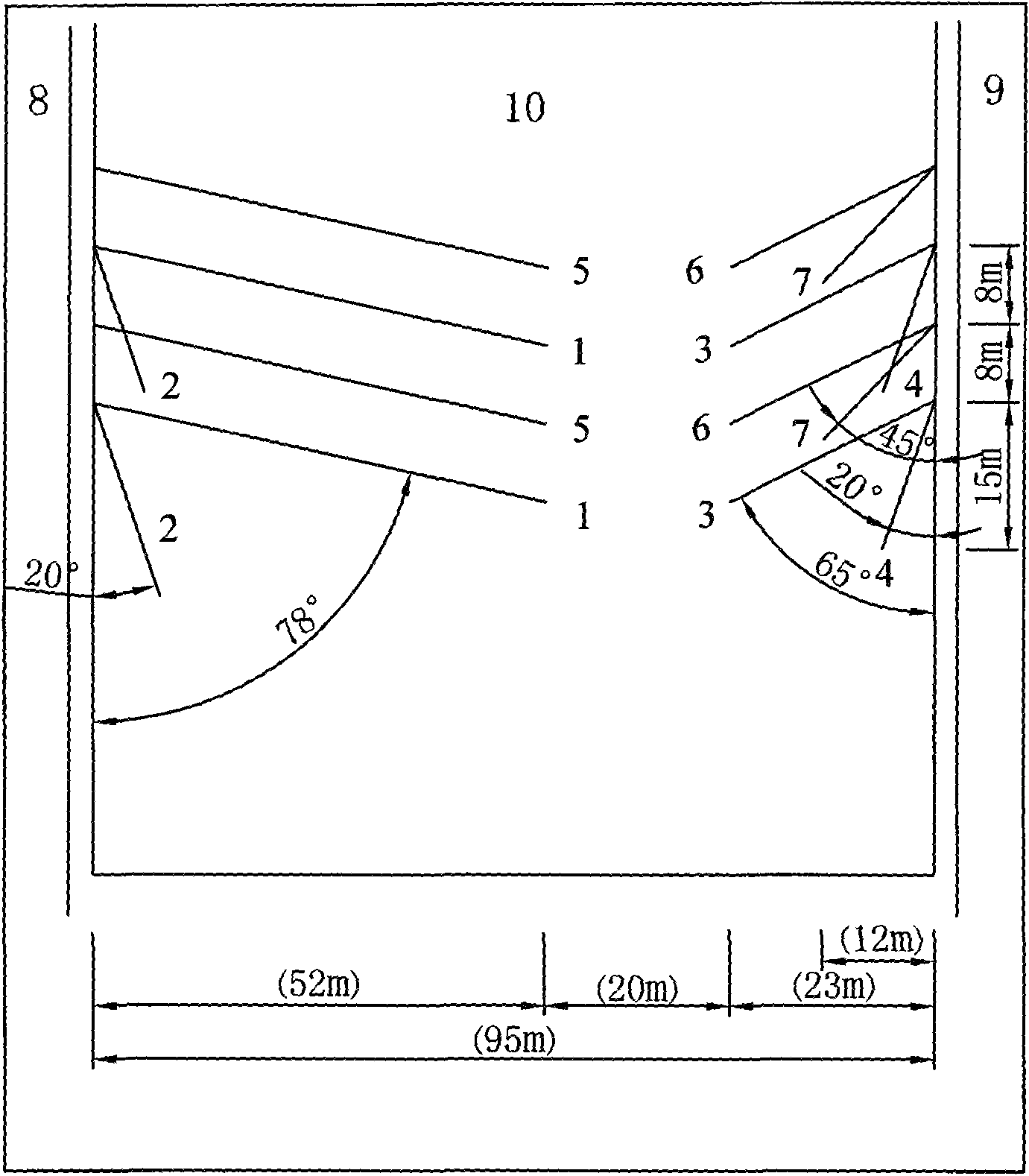

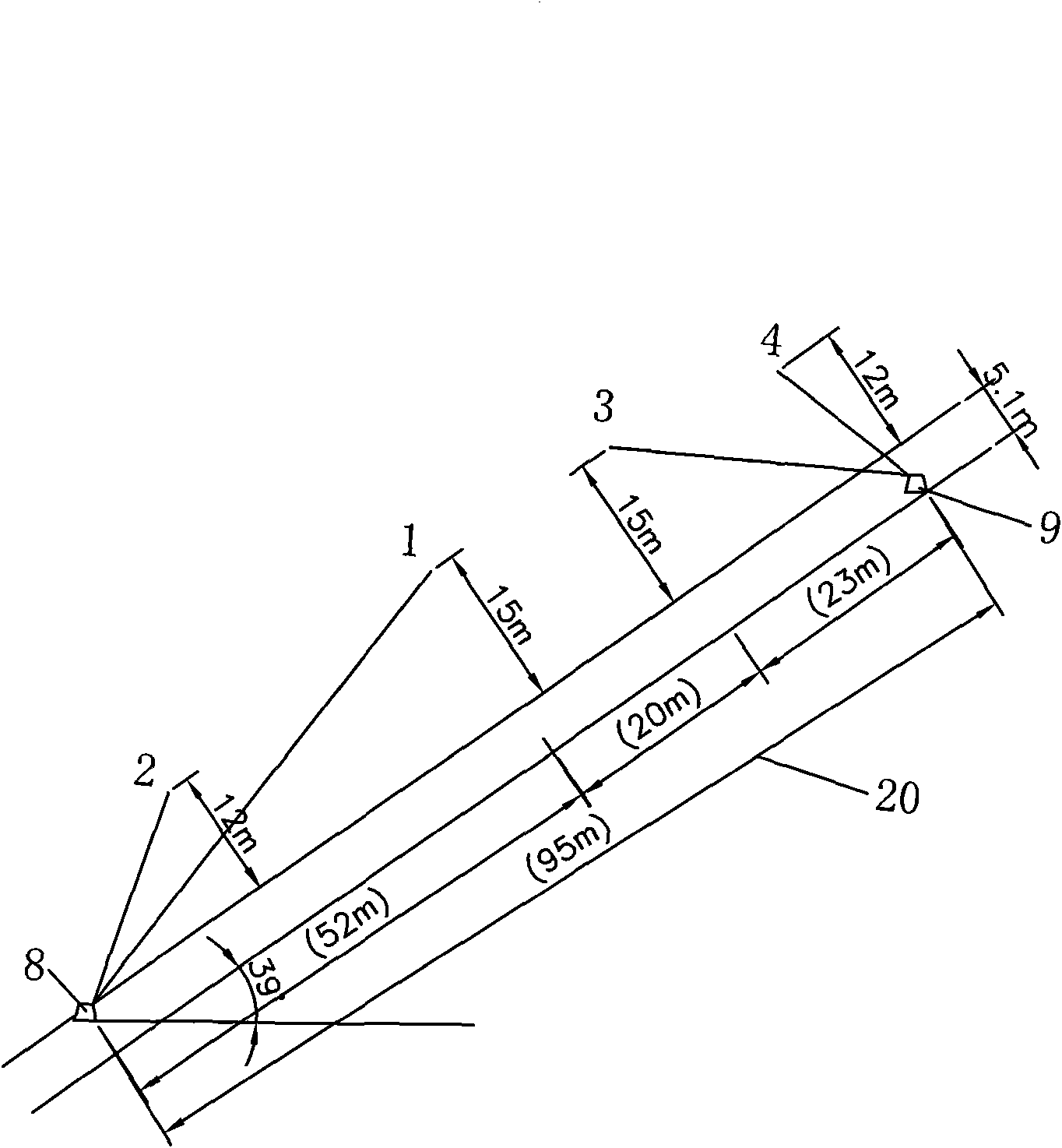

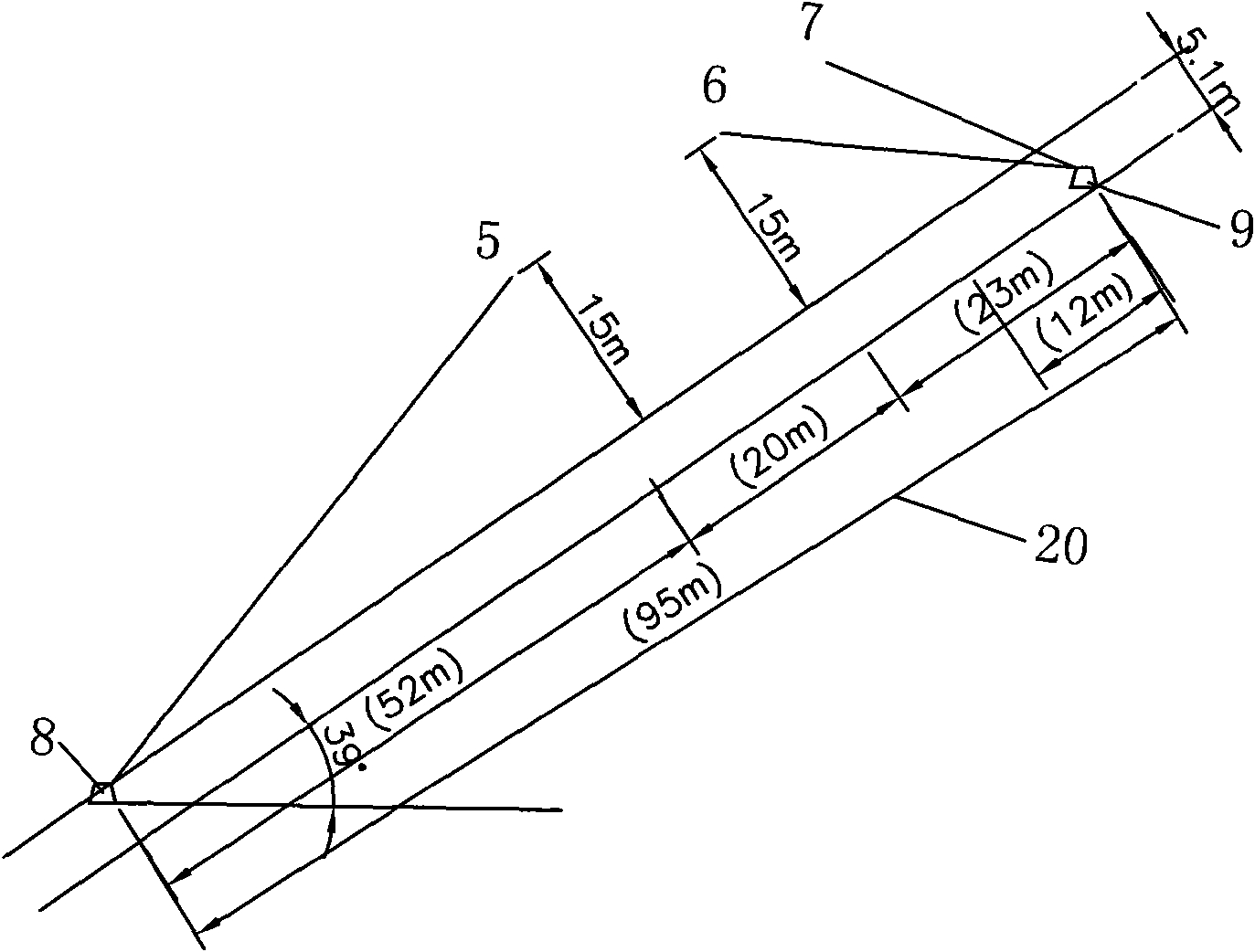

[0020] An advanced pre-blasting technology for a hard roof of a large-inclination coal seam, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, there are non-equal-length blastholes at different angles arranged in the roof rock layer in the front of the working face in the return air and transport lane troughs 9 and 8 inwards to the front of the working face in the circulation top area 10, and the length of the blastholes in the return air trough is short, The included angle with the coal seam is large, the length of the blast hole along the transportation channel is long, and the included angle with the coal seam is small. The internal blasting of the hole destroys the rock under the action of the blast shock wave and the stress wave. The layout of the blast hole is based on the position, total thickness, dip angle and occurrence factors of natural cracks of the old top rock layer, the thickness of the coal seam, and the inclination length of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com