Explosion method for open-cast mining underground goaf position

A technology for open-pit mining and goaf, applied in the field of blasting, can solve the problems of uneven hole network, increased shovel loading, difficulty in transportation process, hanging and not falling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] A method for blasting underground goafs in open-pit mining according to the present invention is characterized in that it comprises the following steps:

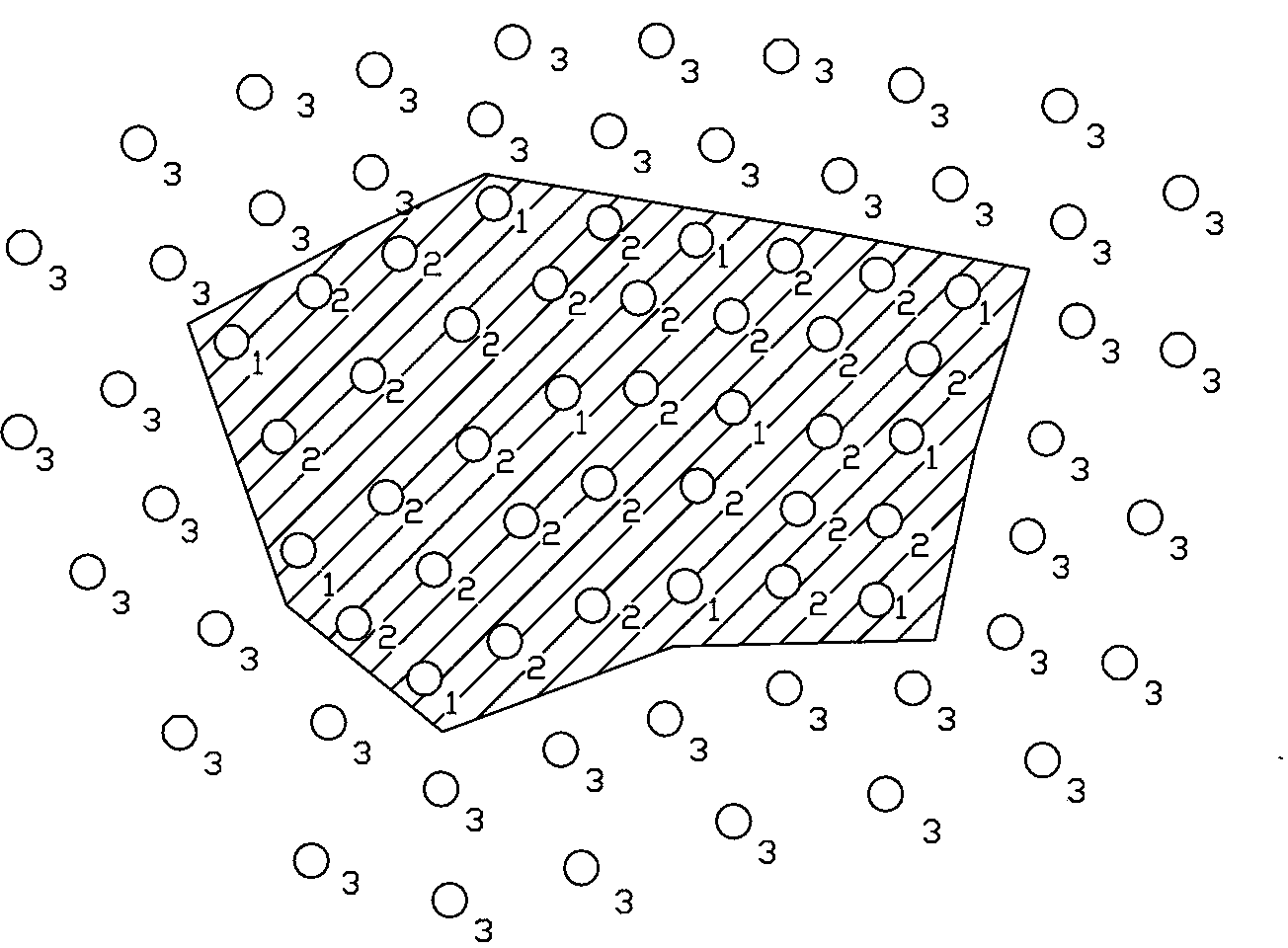

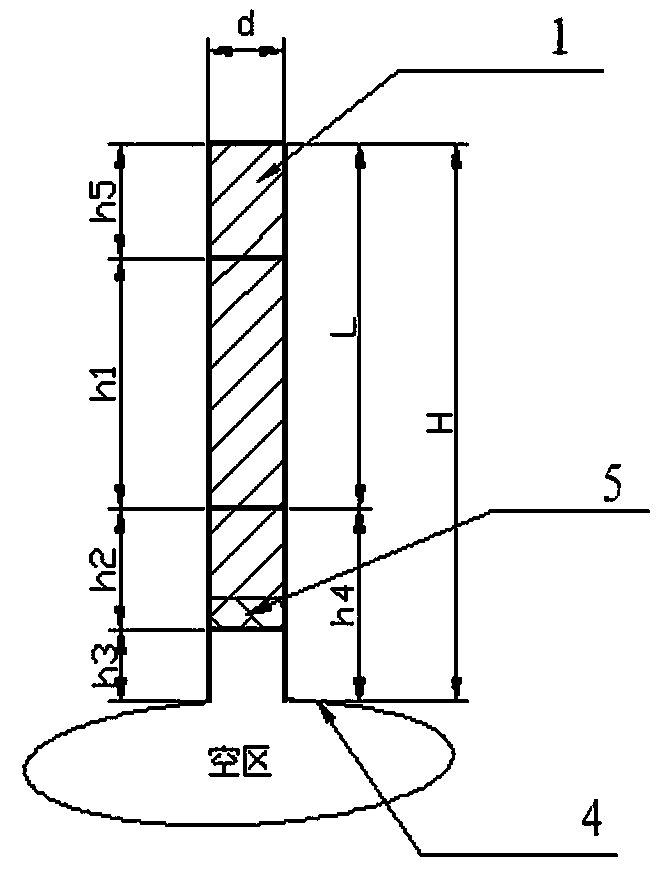

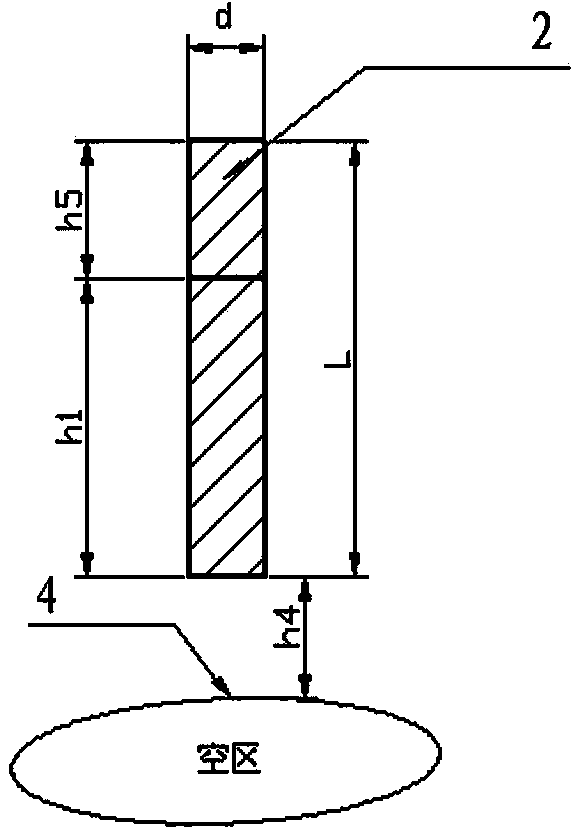

[0038] 1. First, use the shallow seismic image method, high-density resistivity method, and transient electromagnetic method to detect the void area to initially grasp the general shape of the void area, and then according to the detected void area shape, detect the gap at the central roof and peripheral inflection points of the void area. to obtain the accurate shape of the empty space, grasp the thickness of the roof and the internal height of the empty space, and design three types of holes (such as figure 1 ). One type is the penetration hole 1 on the roof of the empty area, that is, the verification hole, which needs to be constructed after calculating the explosive charge and correcting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com