Different-hardness-degree rock stratum blasting control method used in deep-hole bench blasting

A technology of ladder blasting and hardness, applied in blasting and other directions, can solve problems such as insufficient crushing of hard rock layers, difficulty in achieving crushing effect, waste of explosive energy, etc., achieving small drilling coverage, reducing cost and time, and reducing The effect of chunk rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

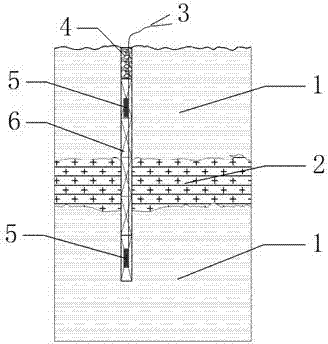

[0027] Such as figure 1 As shown, there is a layer of hard rock formation in the middle of the blast hole along the axial direction, and two detonation points are set.

[0028] A face rockfill dam is mining graded materials. The source lithology of the rock field is basalt, some of which are granite. The basalt rocks are weakly weathered. There is a hard granite layer with a thickness of about 2.0m at the depth of 4-6m in the middle of the rock mass. The rock is dense and hard. The blasthole diameter is 100mm, the blasthole depth is 10m, the plugging length is 1.0m, the hole spacing is 2.5m, and the row spacing is 2.2m. Mixed explosives are used to couple the charges.

[0029] Specifically include the following steps:

[0030] 1. Hole layout and drilling, observe and record rock powder, cuttings and drilling speed.

[0031] In the rock mass of the material yard that needs to be excavated by blasting, the blasthole area is manually cleaned, and the surface is blown with a hi...

Embodiment 2

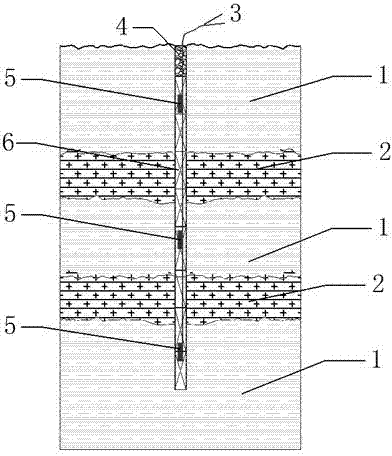

[0039] Such as figure 2 As shown, there are two layers of hard rock formations in the middle of the blast hole along the axial direction, and three detonation points are set.

[0040] The tailings of a copper mine are mined by blasting. There are two layers of copper ore veins in the tailings mine, respectively at the depth of 6.0-8.5m and 12.5-15.5m. The strength of the copper ore is extremely high, and the strength of other rocks is weak of diorite. The blasthole diameter is 120mm, the blasthole depth is 20.0m, the plugging length is 2.0m, and the hole spacing is 4.0m.

[0041] The row spacing is 3.2m, and mixed explosives are used to couple charges.

[0042] Specifically include the following steps:

[0043] 1. Hole layout and drilling, observe and record rock powder, cuttings and drilling speed.

[0044] Manually clean the area to be blasted, and blow the surface with a high-pressure air pipe, and arrange holes in the blast area in strict accordance with the blasting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com