Medium-length hole blasting method used for underground mining

A technology of deep hole blasting and blast hole, which is applied in blasting and other directions, which can solve the problems of reducing mining operation time, low mining efficiency, and poor blasting effect, so as to reduce the number of secondary crushing, ensure operation safety, and improve mining efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

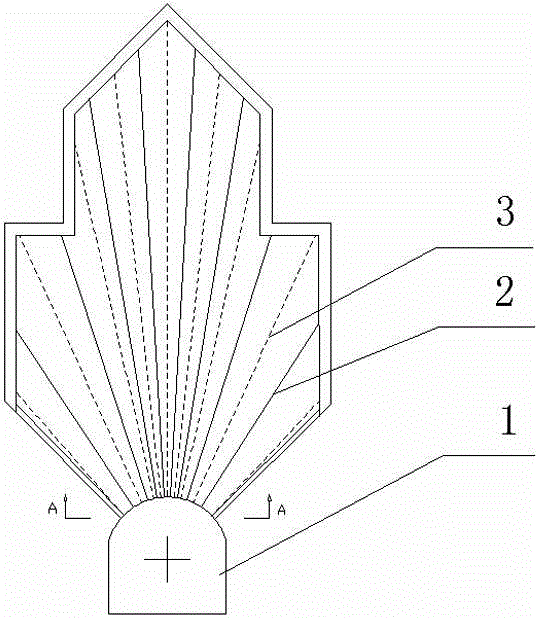

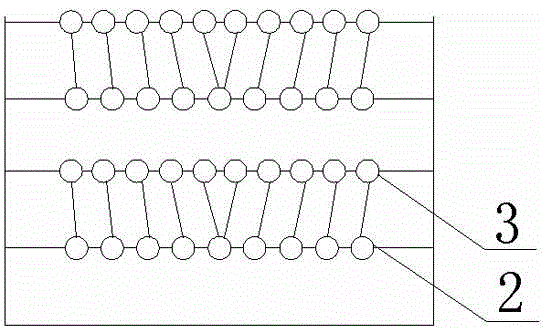

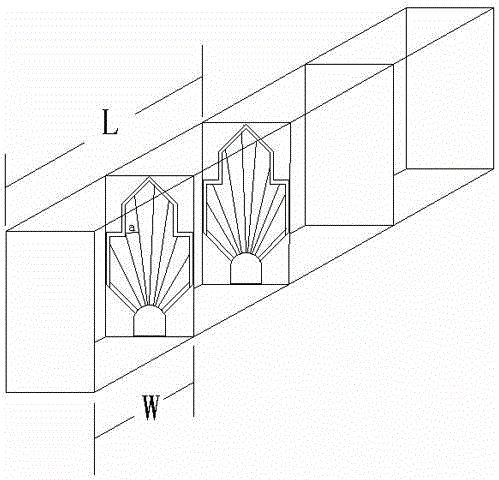

[0026] by Figure 1 to Figure 3 As shown, at least two rows of blast holes are arranged in parallel on the top rock layer of the mining roadway, each row of blast holes is arranged in a fan-shaped arrangement to form a fan-shaped blast hole, and adjacent rows of blast holes are arranged alternately;

[0027] The sector blasthole shall meet the following requirements:

[0028] The blast hole angle is 90°, the blast hole side hole angle is 45°, the blast hole bottom distance a=1.8~2.4m, the blast hole depth is 4.5~13m, the blast hole diameter d=60mm, the minimum resistance of the blast hole Line W=(20~25)d, collapse step distance L=2W, blast hole density coefficient is 1.5~2;

[0029] The minimum resistance line of this arrangement is reasonably matched with the hole bottom distance. While the blasting energy acts between the blastholes, it also affects the rock mass in the direction of the blasting free surface directly in front of the blasthole, and the cracks in the rock mass are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com