Mine water stemming bag and application of mine water stemming bag in borehole blockage

A technology of mining water and water gun mud, which is applied in blasting and other directions, can solve problems such as affecting blasting effect, blasting rejection, and explosives being damp, and achieve efficient and reliable blasting hole blocking effects, reduce labor intensity, and reduce construction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

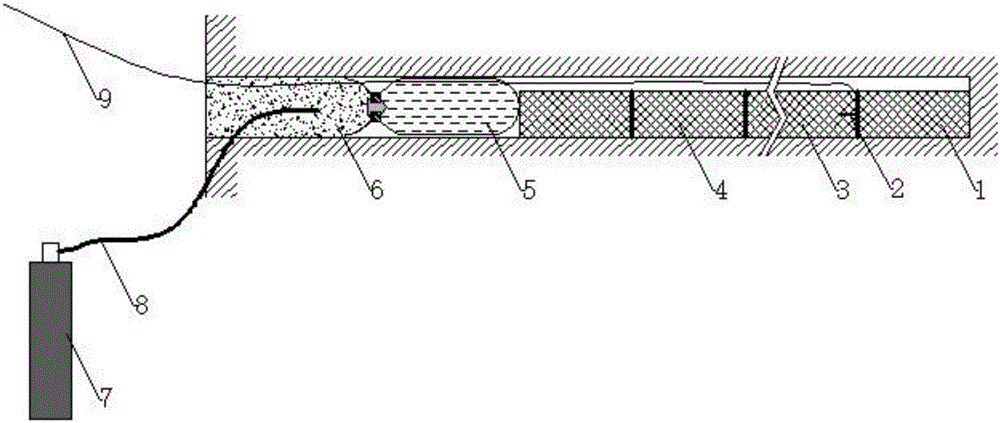

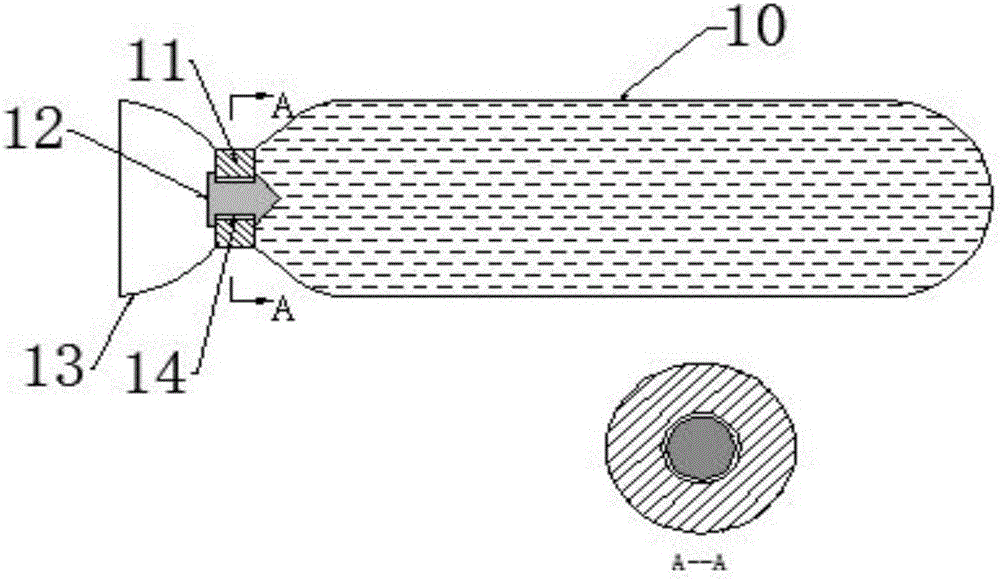

Embodiment 1

[0042] The water gun mud bag of the present invention is combined with the composite material of the present invention to block the blast hole, and it is applied in the strong mining and excavation below the middle section of the 36th pit mouth of the Woxi Gold Mine in Xiangxi. For example, in the extension excavation of the single-headed roadway in the middle section of No. 39, firstly, all the blastholes on the section are constructed on the face of the tunnel using drilling equipment according to the design and construction drawings. The depth of the blastholes is about 2.8m, the diameter is about 40mm, and the number is 51.

[0043] Bunker hole plugging specifically includes the following steps:

[0044] 1) Water cannon mud bag water injection: connect the threaded end of the special water injector of the present invention to a certain joint of the working water pipe, insert the variable-diameter water injection head into the water injection port, open the valve to inject w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com