Heading shaped crack blasting method suitable for high-stress ore bodies

A high-stress, energy-gathering technology, applied in blasting, mining equipment, earthwork drilling, etc., can solve the problems of low energy utilization rate, poor blasting effect, low explosive unit consumption, etc., to increase the range of cracking and increase the amount of blasting , The effect of reducing the unit consumption of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better describe the present invention, a method suitable for advanced energy-gathering fracturing blasting of high-stress ore bodies of the present invention will be further described in detail below in conjunction with the accompanying drawings.

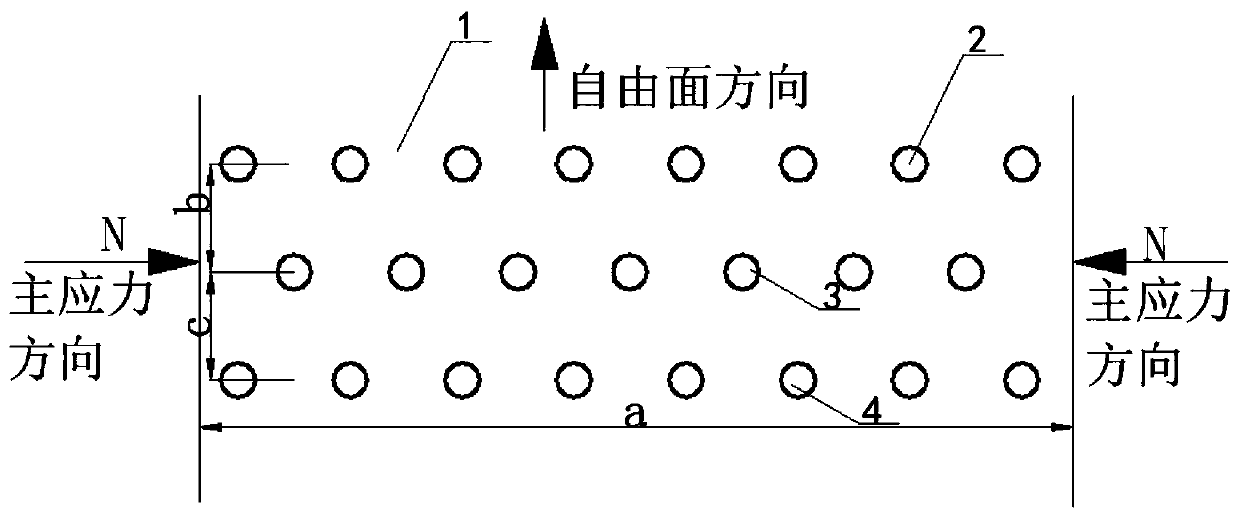

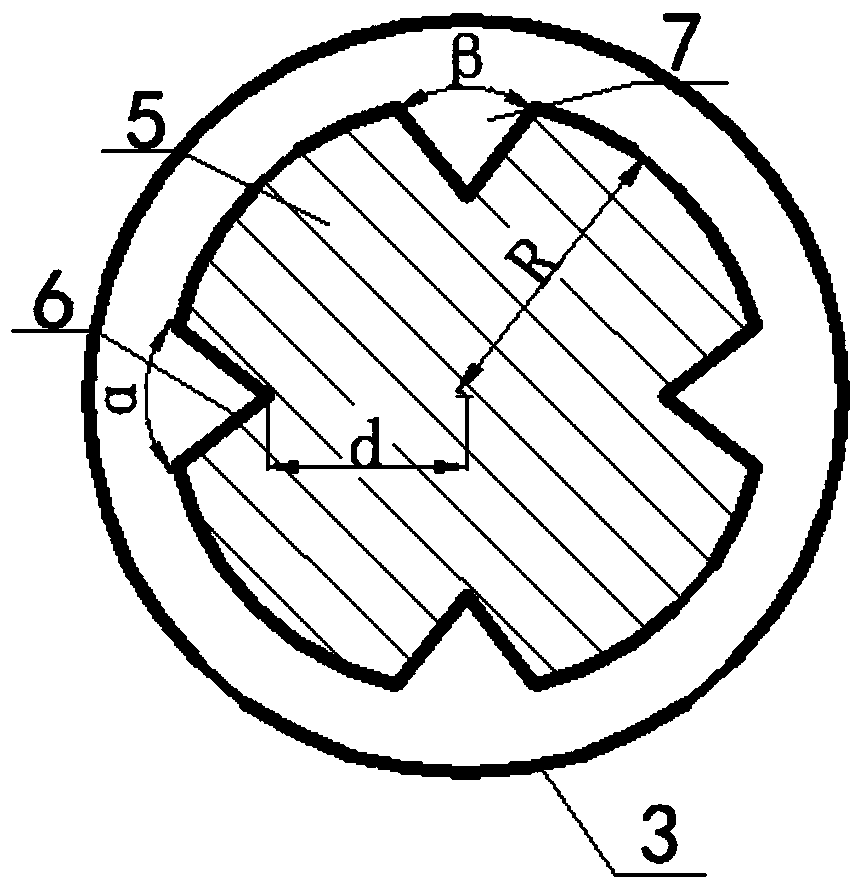

[0023] Depend on figure 1 The shown method of the present invention, which is suitable for advanced energy-gathering fracturing blasting of high-stress ore bodies figure 2 Find out, a kind of method that the present invention is suitable for high-stress ore body advanced energy-gathering fracturing blasting, the width of deep stope 1 is a, adopts retreat type subsection blasting mode in deep stope 1 length direction, in deep stope 1. The front row of main blasting holes 2 and the rear row of main blasting holes 4 are arranged on the blasting ore body. The distance between the front row of main blasting holes 2 and the rear row of main blasting holes 4 is a conventional retreat The segmented blasting method is 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com