Production process and production system of lithium difluorophosphate

A lithium difluorophosphate, production process technology, applied in the field of preparation of lithium difluorophosphate, can solve the problems of increased battery internal resistance, high safety risks, fast battery capacity decay, etc., to improve production efficiency, improve safety, The effect of long reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

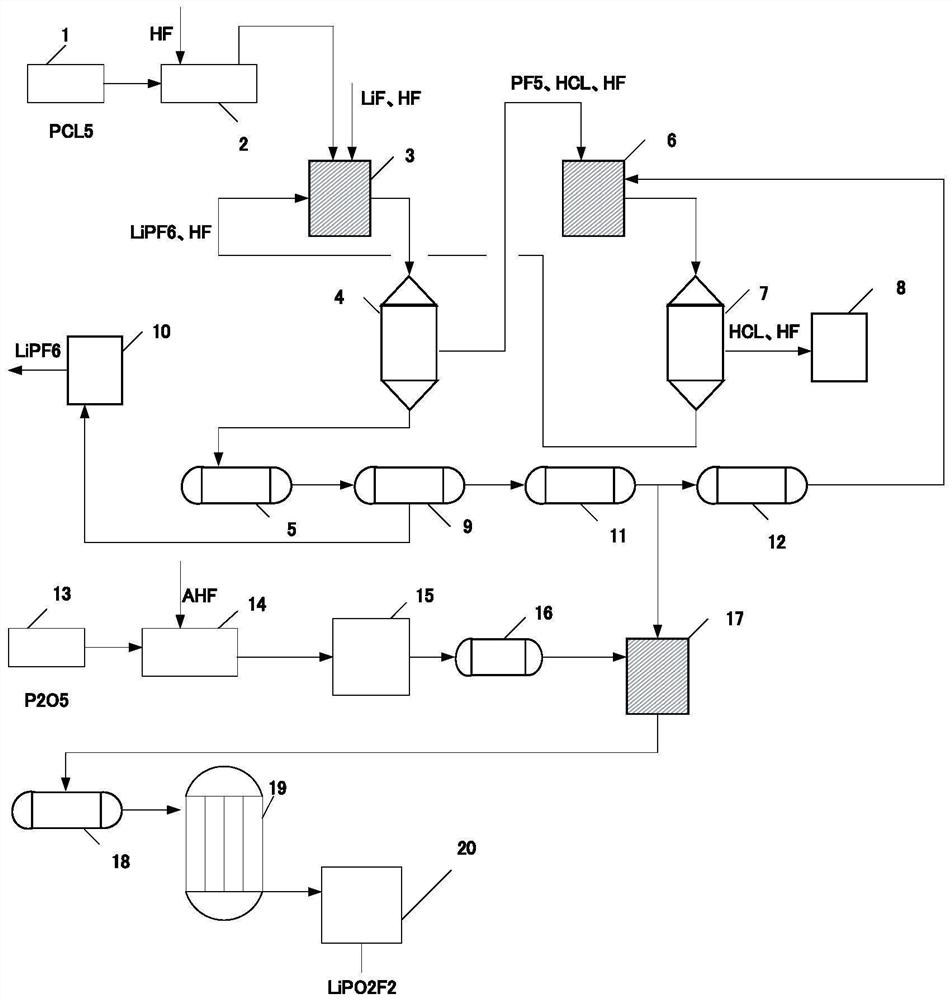

[0051] Preparation of a mother liquor comprising lithium hexafluorophosphate: Phosphorus vials via a solid conveyor 1 with a metering device is delivered to a hydrogenated pentafluoride generator 2 with a cooling jacket, and the control temperature is about 0 ° C. Pentachloride is immediately reacted with hydrogen fluoride to produce pentafluoride and hydrogen chloride. The mixed gas pentafluoride, hydrogen chloride, and the entrained fluoride gas are introduced into the first microchannel reactor 3, constitute the first feed stream. In the dissolution tank with a cooling jacket and a stirrer, hydrogen fluoride is added, and the lithium fluoride is added to the dissolved groove while cooling while cooling, the crystallol is 0 ° C, and the mass fraction of lithium fluoride is 2 wt%. . The hydrogen fluoride solution of the lithium fluoride is transported into the first microchannel reactor 3 with pump to form a second feed stream. The reaction temperature of the first microchannel r...

Embodiment 2

[0057] The present embodiment contains a mother liquor for lithium hexafluorophosphate is prepared as in Example 1.

[0058] Preparation of fluorophosphate: Pentoxide phosphorus is delivered to a solid conveyor 13 with a metering device to be delivered to a fluoride-containing fluorophosphate 14 with a cooling jacket, and pentoxide is 1.5 kg / min. The rate enters the fluorophosphate reactor to form a fluorophosphate solution to the excess water-free hydrogen fluoride, until the phosphorus phosphorus feed is completed, the temperature is controlled at -10 ° C, wherein the molar ratio of pentoxide and no hydrogen fluorine hydrogen fluoride is : 1: 5.1. The mixed solution of the fluorophosphate containing water is introduced into the reduced pressure distillation device 15, the temperature is at 90 ° C, and the hydrophilic fluorophosphate is stored in the fluorophosphate tank 16.

[0059] Preparation of lithium difluorophosphate: the mother liquor containing lithium hexafluorophosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com