Overhand shrinkage spaced-loading split-blasting slot cutting method

A technology of interval charging and pulling troughs, which is applied in ground mining, underground mining, special mining, etc., and can solve problems such as high rate of large ore chunks, prone to overhanging troughs, complex construction organization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples further illustrate the invention, but do not limit it in any way.

[0028] A slotting method for step-by-step blasting with interval charges for upward ore retention, comprising the following steps:

[0029] The first step, the determination of the geometric parameters of the cutting entry

[0030] 1. Determination of the position of the cutting lane

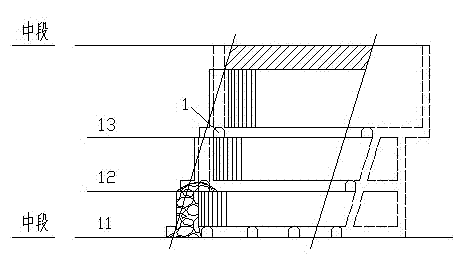

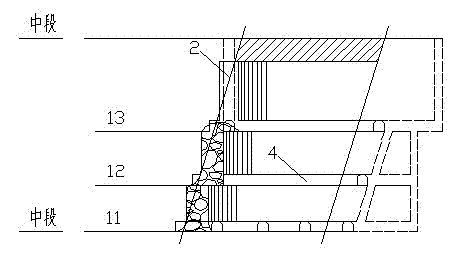

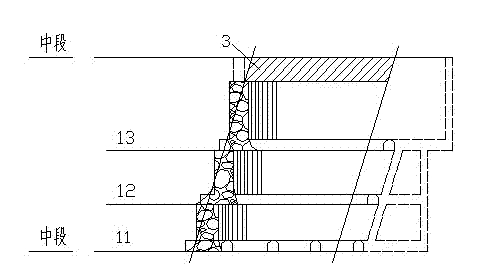

[0031] According to the needs of rock drilling and blasting, the cutting level entry 1 and the cutting patio 2 are constructed at a reasonable position in the mine house. Several rows of fan-shaped medium-deep holes are drilled on both sides of the cutting patio 2 and in the cutting entryway 1, with the cutting patio 2 as the free surface and the cutting entryway 1 as the working space. groove.

[0032] The ore block is arranged along the ore body strike (the first form), and the centerline of cutting headway 1 is parallel to the centerline of the ore pillar. Until the last row of grooves in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com