Blast hole uncoupling energy gathering spacing device suitable for non-coal mine mountain and using method thereof

A spacer and blast hole technology, which is applied in the field of blast hole uncoupling energy-gathering spacer, can solve the problems of low control ability, uncoupling charge blasting effect, and high production cost, so as to reduce the large block rate and improve the blasting rate. Safety factor, effect of reducing flying stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

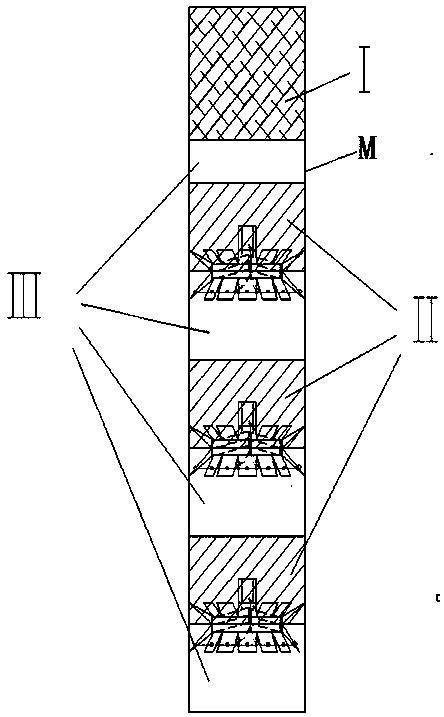

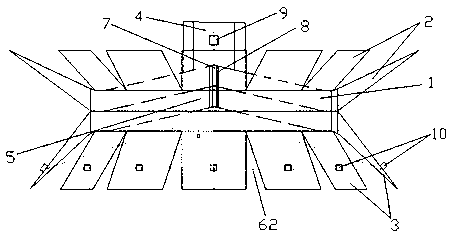

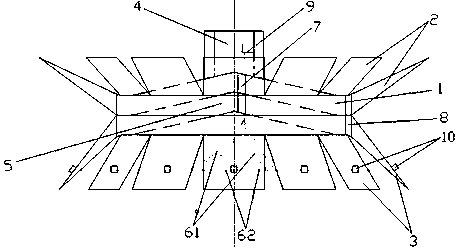

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0037] The non-coupling energy-gathering spacing device for blastholes applicable to non-coal mines of the present invention includes a tray body 5 and an upper barb 2 and a lower barb 3 arranged on the outer periphery of the tray body 5 for clamping the hole wall, and the tray body 5 includes barbs The conical disk body K and the internally threaded post 4 with internal thread on the upper surface of the inverted conical disk body K, the inverted conical disk body can be solid material or hollow, the inverted conical disk body K A copper sheet 1 is connected to the periphery, and the upper barb 2 and the lower barb 3 are connected to the outer peripheral surface of the copper sheet 1. The inner wall of the internal thread column 4 is provided with a hanging rubber band buckle 9, which is located on the inner side of the inverted tapered disc bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com