Low-density rock powder emulsion explosive and method thereof

A powdery emulsion explosive, low-density technology, applied in the directions of explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc. problems, to achieve the effect of reducing toxic gas emissions, excellent explosive performance, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

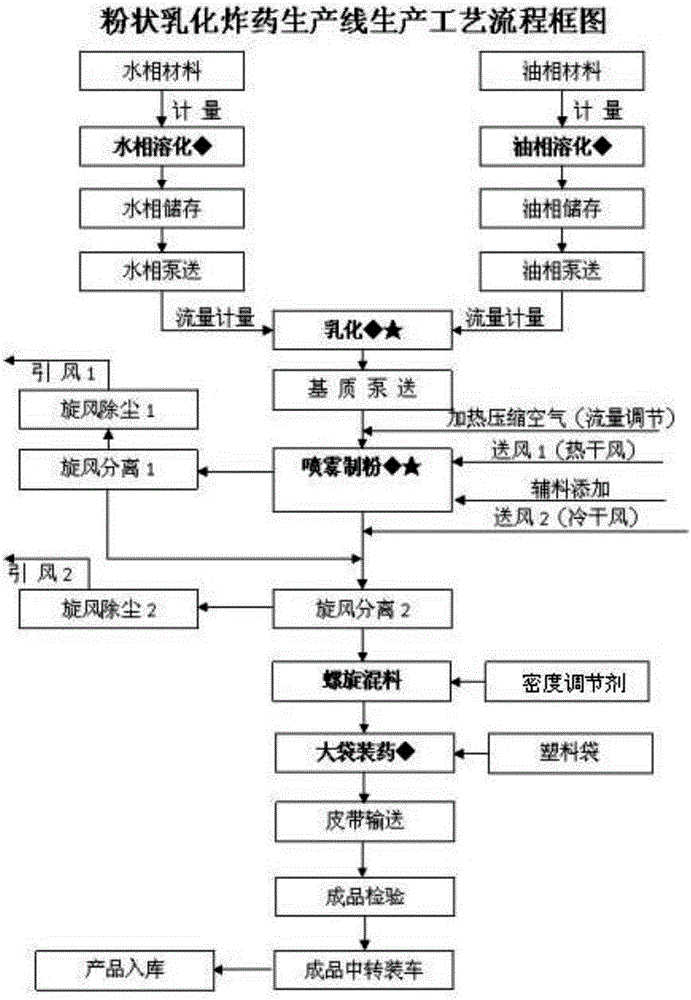

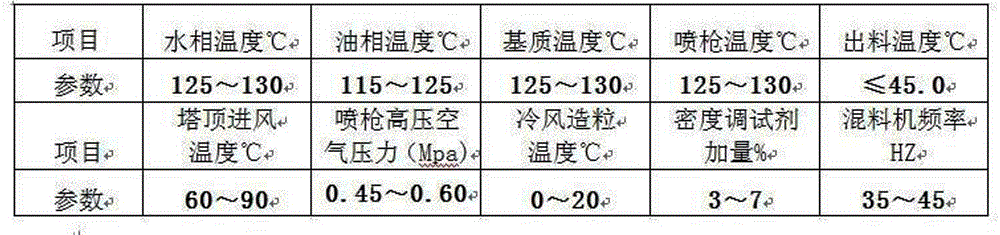

Method used

Image

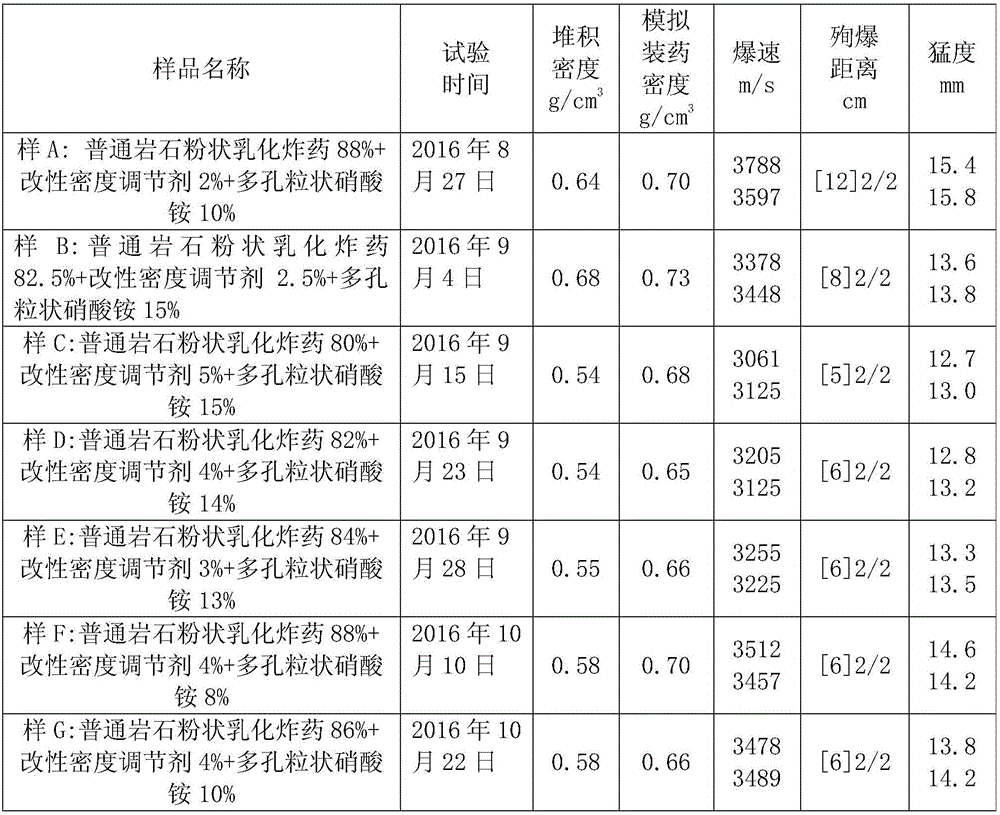

Examples

Embodiment 1

[0022] Embodiment 1: A kind of low-density rock powdery emulsion explosive, this explosive is prepared from following raw material: common rock powdery emulsion explosive 88%, modified density adjuster 4%, porous granular ammonium nitrate 8%; Wherein common rock The powdery emulsion explosive consists of 91% ammonium nitrate, 3.5% water, and 5.5% composite oil phase; the formula of ordinary rock powdery emulsion explosive does not contain toxic substances such as TNT, and has excellent explosive performance, strong water resistance, and good fluidity , easy to use and easy to fill the blast holes, etc.;

[0023] The modified density regulator formula is: expanded perlite 81%, diesel oil 19%; The modified density regulator in the present embodiment is expanded perlite (45~60kg / m 3 ) is modified by adding diesel oil. Diesel oil and puffed perlite are added and mixed in proportion to allow puffed perlite particles to adhere to diesel oil and change its dispersion and suspension ...

Embodiment 2

[0029] Embodiment 2: A kind of low-density rock powdery emulsion explosive, this explosive is prepared from following raw materials: common rock powdery emulsion explosive 80%, modified density regulator 5%, porous granular ammonium nitrate 13%; The composition of rock powder emulsion explosives is: 89% ammonium nitrate, 5% water, and 6% composite oil phase; the formula of ordinary rock powder emulsion explosives does not contain toxic substances such as TNT, and has excellent explosive performance, strong water resistance, and fluidity. Good, easy to use and easy to fill the blast hole and so on;

[0030] Modified density regulator formula is: expanded perlite 80%, diesel oil 20%; Modified density regulator in the present embodiment is expanded perlite (50~55kg / m 3 ) is modified by adding diesel oil. Diesel oil and puffed perlite are added and mixed in proportion to allow puffed perlite particles to adhere to diesel oil and change its dispersion and suspension properties in ...

Embodiment 3

[0036] Embodiment 3: A kind of low-density rock powdery emulsion explosive, this explosive is prepared from following raw material: common rock powdery emulsion explosive 90%, modified density regulator 3%, porous granular ammonium nitrate 7%; The composition of rock powder emulsion explosives is: 92% ammonium nitrate, 3% water, and 5% composite oil phase; the formula of ordinary rock powder emulsion explosives does not contain toxic substances such as TNT, and has excellent explosive performance, strong water resistance, and fluidity. Good, easy to use and easy to fill the blast hole and so on;

[0037] Modified density regulator formula is: expanded perlite 85%, diesel oil 15%; Modified density regulator in the present embodiment is expanded perlite (55~60kg / m 3 ) is modified by adding diesel oil. Diesel oil and puffed perlite are added and mixed in proportion to allow puffed perlite particles to adhere to diesel oil and change its dispersion and suspension properties in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com