Drivage peripheral hole homoenergetic blasting method

A peripheral and roadway technology, which is applied in the field of peripheral hole blasting in roadway excavation, can solve the problems of difficult to accurately control the length of the air column, unsuitable for large-scale application, and large labor workload, so as to improve energy utilization, avoid excessive concentration and weakening. damage damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better describe the present invention, a method for blasting all the surrounding holes of roadway excavation according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

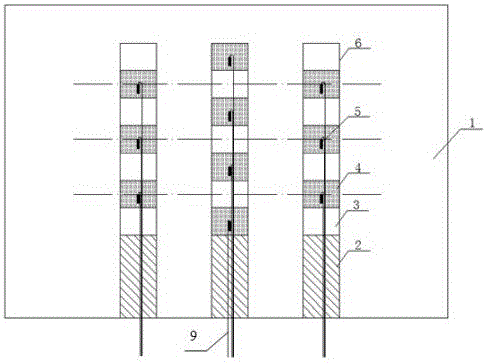

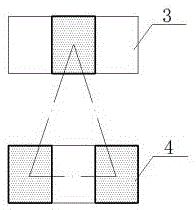

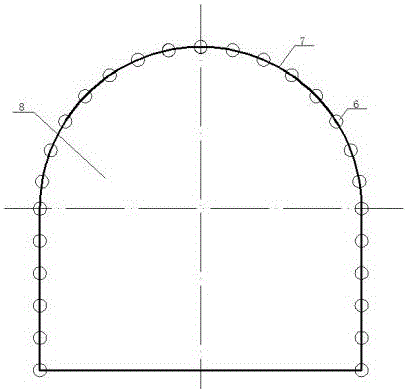

[0019] Depend on image 3 The peripheral hole adopted by the present invention is shown in the roadway section position distribution diagram and combined with figure 1 , figure 2 It can be seen that a method for blasting peripheral holes of a kind of roadway excavation of the present invention, first on the roadway contour line 7 of the surrounding rock 1 at the end of the roadway 8, excavate the peripheral holes 6 according to the designed hole network parameters, and the diameter of the peripheral holes 6 is 38mm~42mm, length 2.5m~3m, each section of cushioning material 3 length 0.2m~0.3m. After the inspection of the drilling parameters is completed, the explosives 4, cushioning materials 3 or cushioning materials 3, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com