A process control method for laser 3D printing of aluminum alloy modified by rare earth with low element burning loss

A rare earth modification and 3D printing technology, applied in the field of aluminum alloy materials, can solve the problems of difficult rapid heat conduction, rare earth element evaporation burning, rare earth element burning, etc., to improve the flow spreading performance, effectively control and reduce, reduce The effect of evaporative burn loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present invention is a process control method for laser 3D printing of rare earth modified and enhanced aluminum alloy with low element burning loss, including powder spreading and laser scanning; specifically, it includes the following steps:

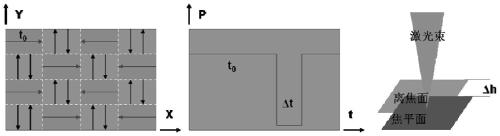

[0050] (1) Establish a three-dimensional model of the formed sample and carry out path planning; the laser scanning strategy adopted includes: using 2mm×2mm partitions, continuous scanning areas are separated by 4 blocks, and the pause at the end of each scanning vector is Δt=0.02s.

[0051] (2) The layered slicing model is imported into the industrial computer of the forming equipment.

[0052] (3) Adjust the forming substrate so that the focal plane is Δh=1700 μm below the forming substrate.

[0053] (4) The pre-alloyed powder is pretreated, the atmosphere used is hydrogen plus argon, the hydrogen content is 10%, the heating temperature is 120°C, and the holding time is 4h.

[0054] (5) Quickly pour pre-alloyed powder (al...

Embodiment 2

[0061] The present invention is a process control method for laser 3D printing of rare earth modified and enhanced aluminum alloy with low element burning loss, including powder spreading and laser scanning; specifically, it includes the following steps:

[0062] (1) Establish a three-dimensional model of the formed sample and perform path planning; the laser scanning strategy adopted includes: using 2mm×2mm partitions, continuous scanning areas are separated by 3 blocks, and the pause at the end of each scanning vector is Δt=0.03s.

[0063] (2) The layered slicing model is imported into the industrial computer of the forming equipment.

[0064] (3) Adjust the forming substrate so that the focal plane is Δh=1600 μm below the forming substrate.

[0065] (4) The pre-alloyed powder is pretreated, the atmosphere used is hydrogen plus argon, the hydrogen content is 15%, the heating temperature is 130°C, and the holding time is 3h.

[0066] (5) Pour the powder quickly, close the ca...

Embodiment 3

[0072] The present invention is a process control method for laser 3D printing of rare earth modified and enhanced aluminum alloy with low element burning loss, including powder spreading and laser scanning; specifically, it includes the following steps:

[0073] (1) Establish a three-dimensional model of the formed sample for path planning. The laser scanning strategy adopted includes: using 2mm×2mm partitions, continuous scanning areas are separated by 2 blocks, and the end of each scanning vector is paused

[0074] Δt = 0.05s.

[0075] (2) The layered slicing model is imported into the industrial computer of the forming equipment.

[0076] (3) Adjust the forming substrate so that the focal plane is Δh=1500 μm below the forming substrate.

[0077] (4) The pre-alloyed powder is pretreated, the atmosphere used is hydrogen plus argon, the hydrogen content is 20%, the heating temperature is 150°C, and the holding time is 2h.

[0078] (5) Pour the powder quickly, close the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com