High sublevel double-hexagon caving mining method

A caving mining and double hexagonal technology, which is applied in the field of high-section double hexagonal caving mining, can solve the problems of large amount of mining and cutting works, high loss rate and high cost, so as to improve economic benefits, improve recovery rate, The effect of reducing the chunk rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

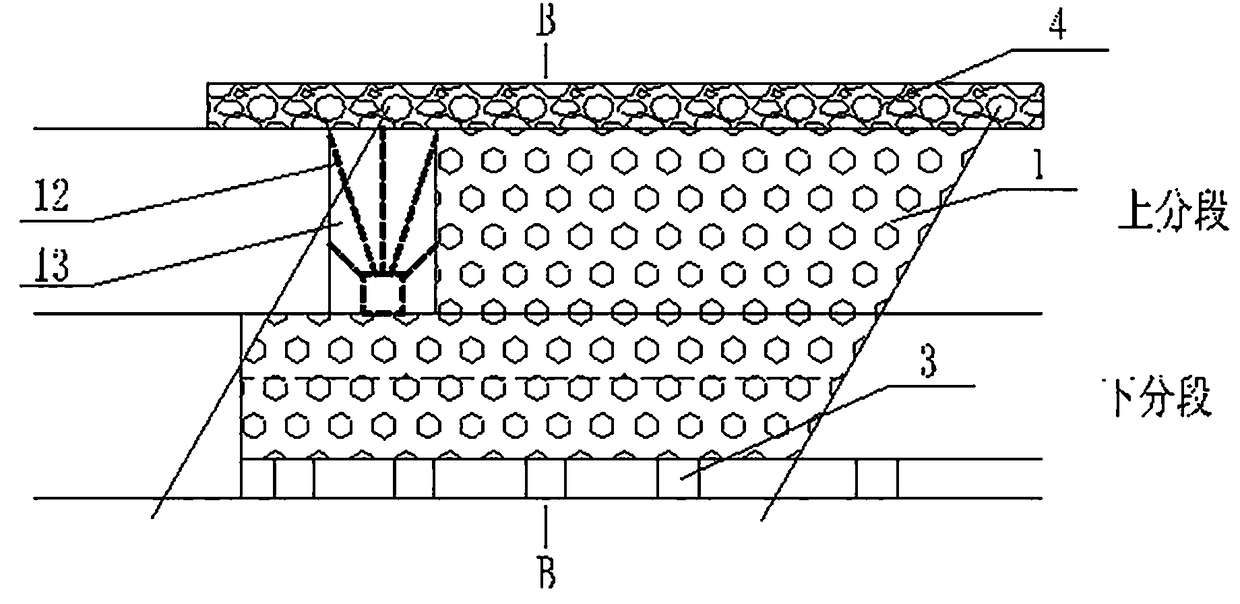

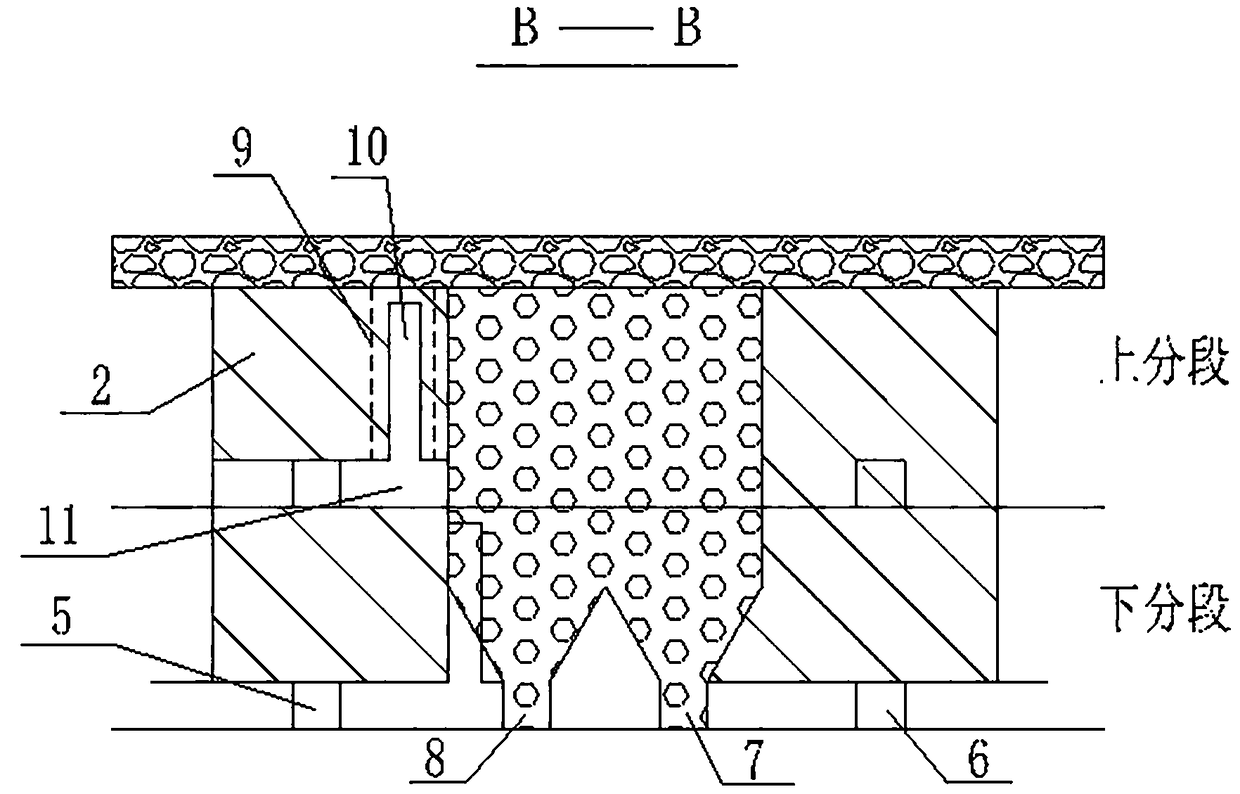

[0022] Such as Figure 1-2 As shown, a high segmental double hexagon caving mining method, the method is carried out according to the following steps:

[0023] Step 1: Use the upper and lower plate combined mining standard system to carry out mining and cutting, the cutting roadway 11 is arranged along the boundary of the upper wall of the ore body, and the cutting shaft 10 and the cutting roadway 11 are combined to form the cutting groove 13 space, and the cutting shafts 10 are staggered between the sections Arrangement, with the cutting well 10 as the free surface, the cutting groove 13 with a width of 4-5m and a height of 14m is formed by blasting in stages, and the slotting hole 9 required for the cutting groove 13 has a hole diameter of 60mm, a side hole angle of 60°, and a row spacing of 1.0m. The hole bottom distance is 1.6-1.8m, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com