Hard roof directional pressurized explosion control method

A technology with a hard roof and a control method, applied in blasting and other directions, can solve the problems of increasing the permeability of coal and rock mass, large uncoupling space for charge, large amount of dust and harmful gas, etc., to improve the utilization rate of explosion energy and the effect of dust reduction. Good, less harmful gas generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below in conjunction with the segmental sequential detonation directional blasting control of the hard and thick roof in the accompanying drawings.

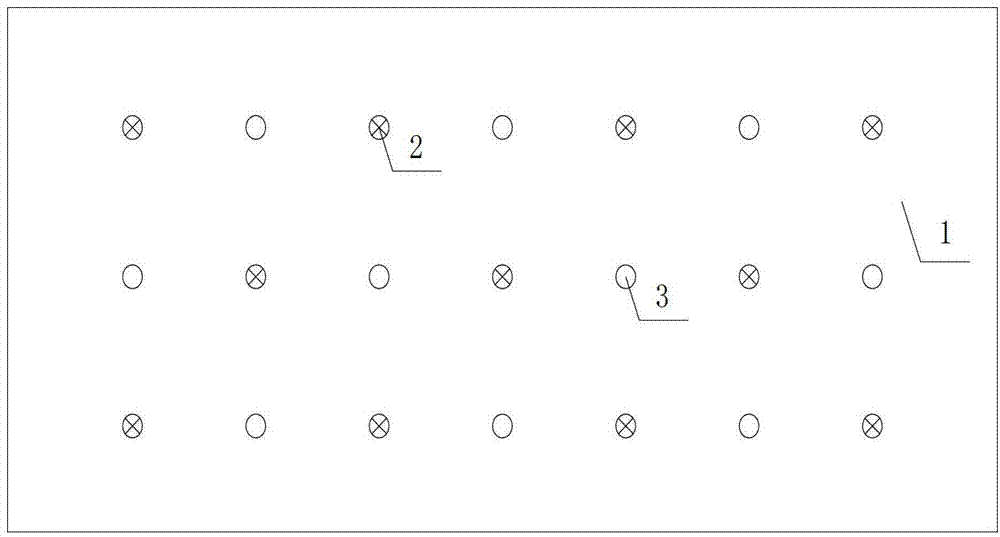

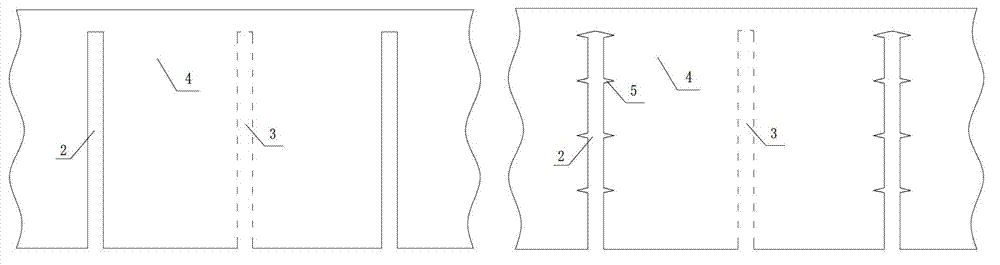

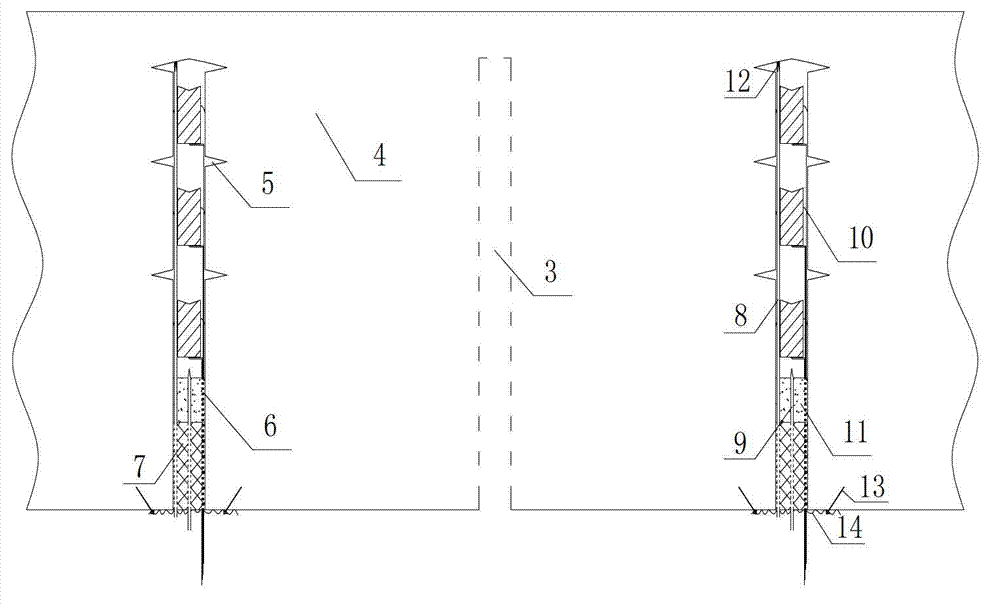

[0020] For the control of the hard and thick roof, the row spacing between the drilled holes should be determined first according to the characteristics of the roof itself, and its size is generally 5-15m. figure 1 As shown, charge holes 2 and guide holes 3 are charged alternately at intervals; secondly, depending on the thickness of the roof and the depth of the drilling, it is determined whether to drill the hard roof into the cutting groove 5 and the number of cutting grooves, such as figure 2 As shown, for a hard roof with a thickness greater than 5m, high-pressure water or a special slotting drill bit should be used to drill and cut grooves, and the greater the thickness of the roof, the higher the strength, and the corresponding increase in the number of drilled grooves. About...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com