Non-symmetric non-coupling refined charging sleeve device

A fine makeup and casing device technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of poor quality of smooth blasting, low charge efficiency, and inability to accurately control the charge structure, etc., to improve the regularity of the contour Speed, accurate control, and the effect of improving the utilization rate of explosion energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

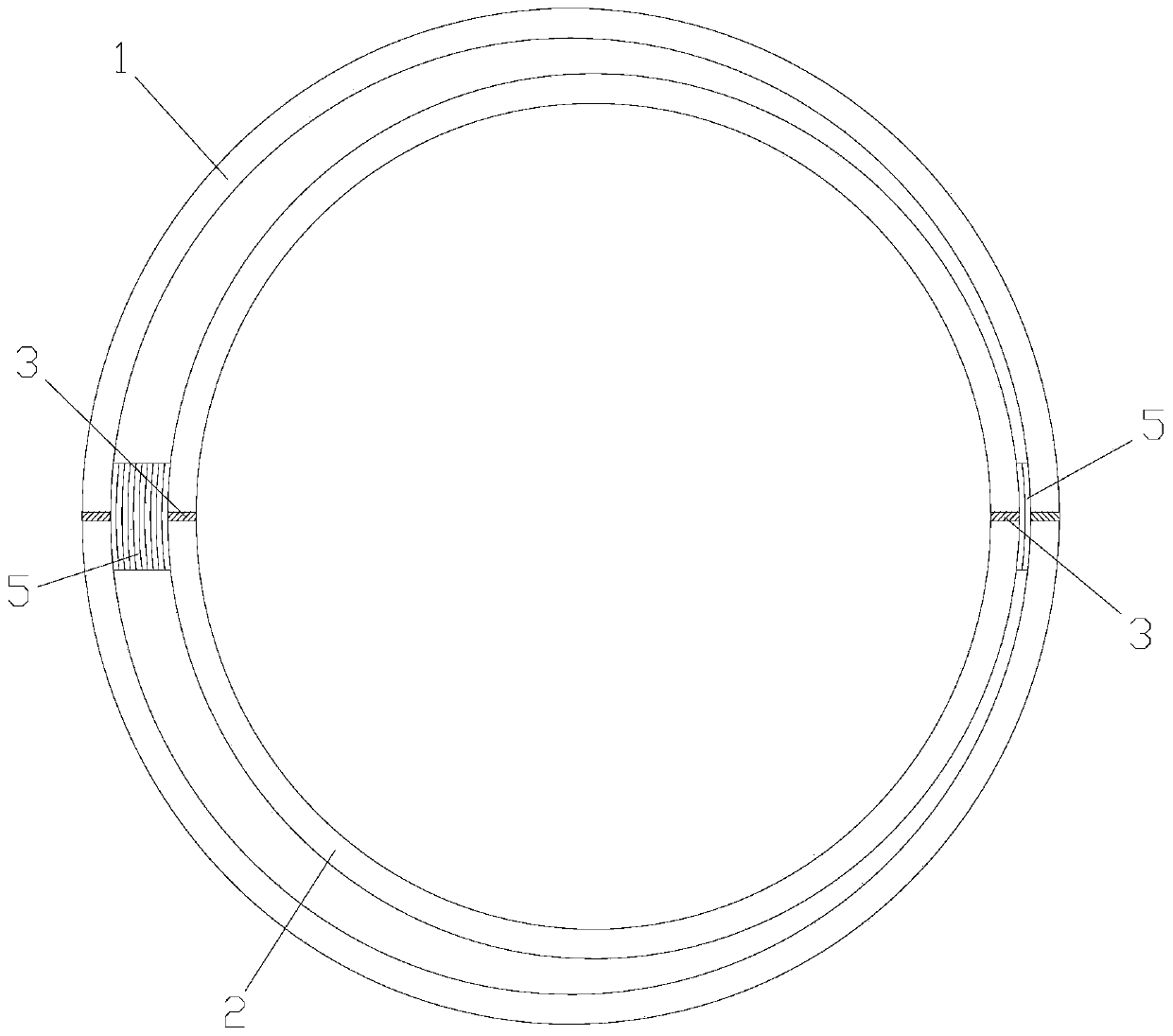

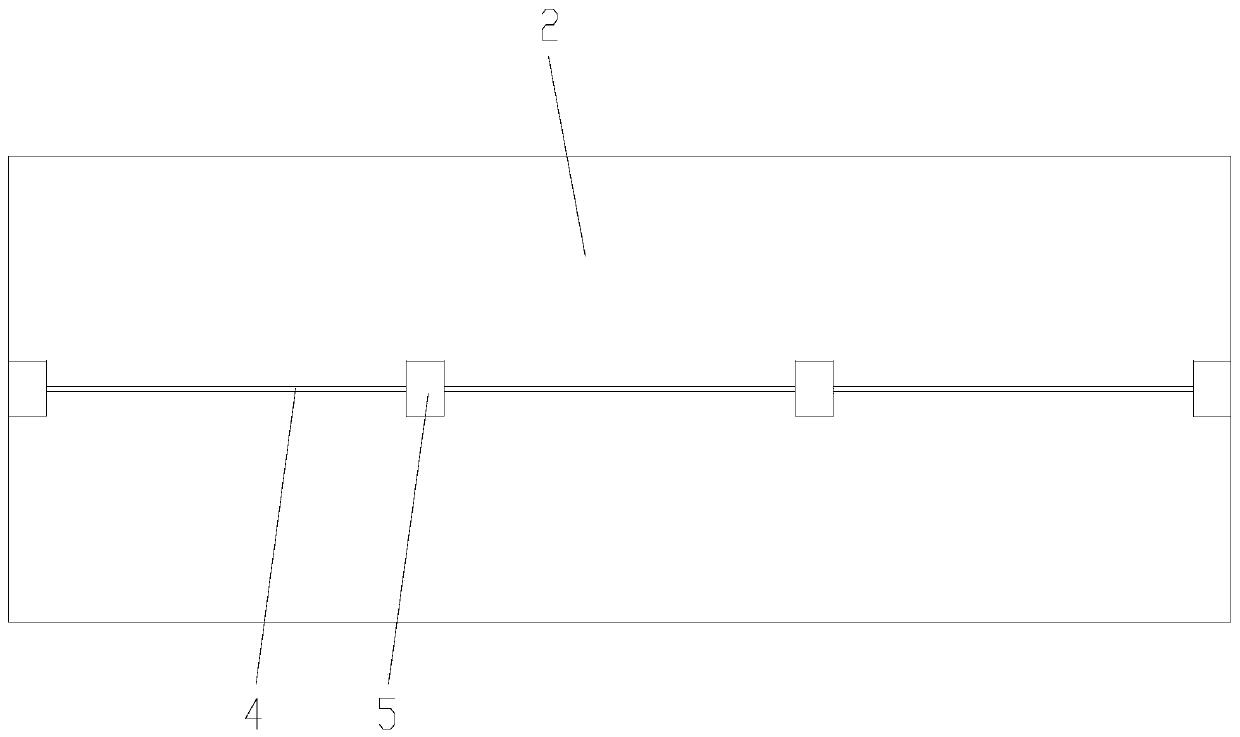

[0015] As shown in the figure, the asymmetric non-coupling refined charge sleeve device in this embodiment includes an outer sleeve 1 and an inner sleeve 2 arranged in the outer sleeve, and the inner sleeve is used for placing explosives.

[0016] In this embodiment, the asymmetric uncoupled and finely charged sleeve device also includes marking grooves 3 arranged on the end faces of the inner sleeve. The connecting line of the marking groove at 1 intersects the center line of the inner sleeve, and the outer surface of the inner sleeve is provided with a marking line 4 connecting the marking grooves at both ends, and the marking line is parallel to the center line of the inner sleeve.

[0017] In this embodiment, the asymmetric non-coupling refined charge sleeve device also includes an eccentric adjustment block 5 arranged between the outer sleeve and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com