A Smooth Fine Blasting Method Based on Precharge

A pre-installed and refined technology, applied in blasting, earth-moving drilling, mining equipment, etc., can solve the problems of inability to precisely control the charge structure, difficult to achieve smooth blasting effect, irregular operation, etc. Improve the efficiency of charging and improve the effect of contour regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] As shown in the figure, this embodiment is based on the smooth surface fine blasting method of pre-charged powder, including the following steps:

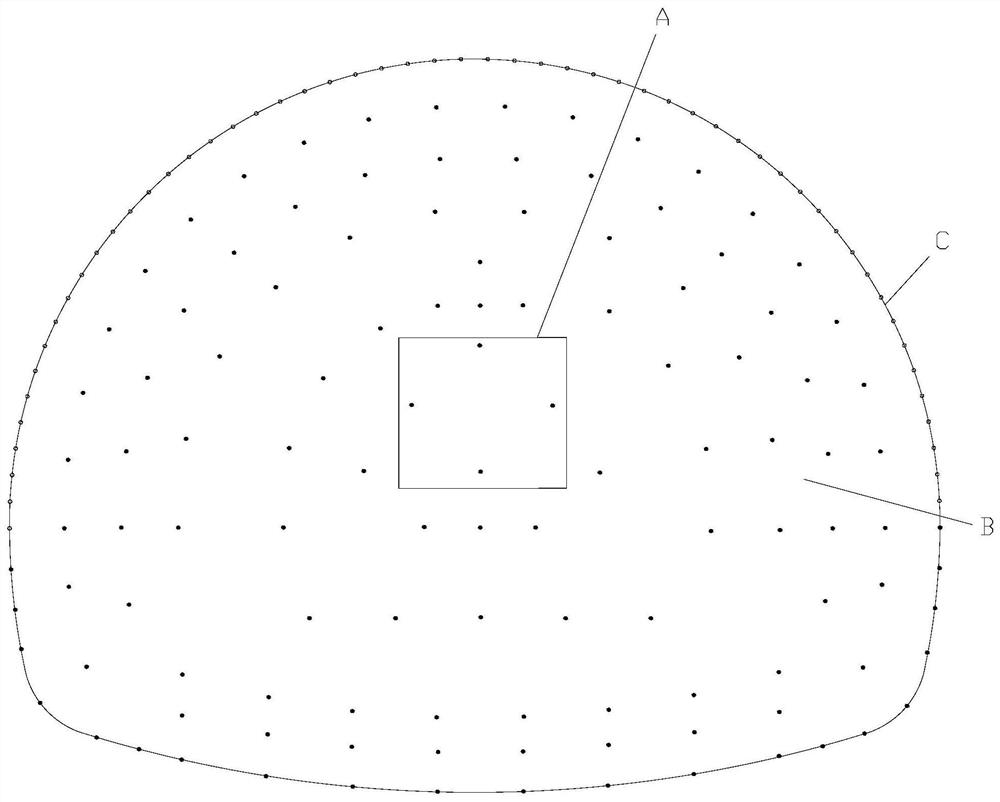

[0027] 1) Sequentially arrange cutting blasting holes inside the tunnel face, arrange several layers of auxiliary blasting holes in the middle of the tunnel face, and arrange smooth blasting blastholes at the periphery of the tunnel face.

[0028] 2) Carry out on-the-spot loading of explosives to the notch blasting holes and the auxiliary blasting holes.

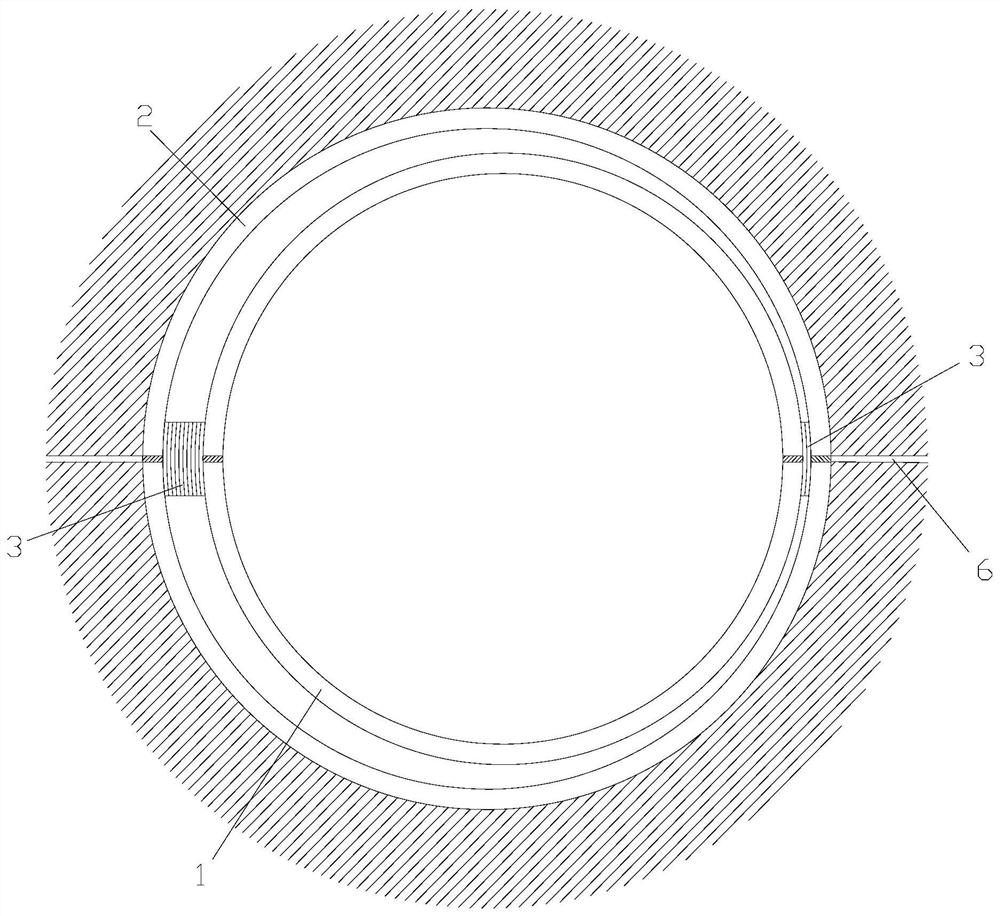

[0029] 3) Carry out accurate asymmetric uncoupled charge to the smooth surface blasting blasthole, which includes the following steps:

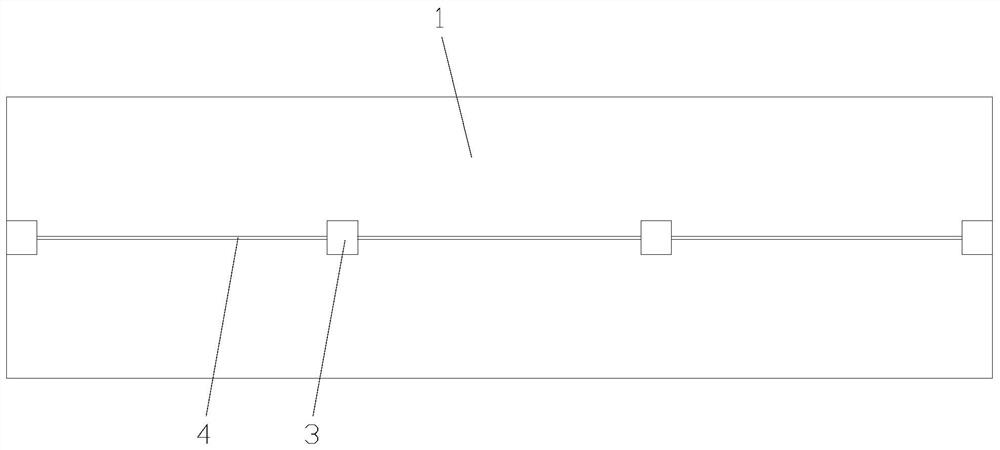

[0030] a. Preloaded medicine outside the hole:

[0031] Set up a specific pre-charged place outside the blasting area for pre-loading outside the hole;

[0032] According to the requirements of blasting design, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com