Loading method suitable for field mixed loading of explosive and tool used for method

A technology of mixing explosives and explosives on site, which is applied in blasting and other directions, can solve the problems of increased blasting cost, loss of explosives, strong blast impact load, etc., achieve uniform charge in the axial direction of the blast hole, improve utilization rate and blasting operation safety , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

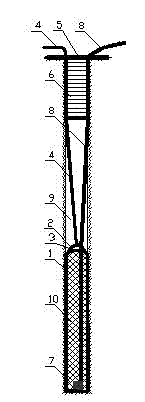

[0026] Embodiment 1: the charge method in the broken rock mass:

[0027] In a mine slope treatment project, the rock mass in some sections of the slope was broken, and there were 10-30cm open cracks in special sections, which needed to be excavated by blasting. The blasting design borehole is 15.0m deep, the hole diameter is 200mm, the charge length at the bottom of the hole is 5.0m, the charge column diameter is 200mm, and the plugging section is 3.0m long. The mixed explosive vehicle is used to charge the charge. The specific implementation method is as follows:

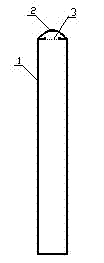

[0028] In the first step, an explosive molding bag 1 with a diameter of 200 mm and a length of 5.1 m is selected.

[0029] In the second step, the prepared detonating bomb 7 is put into the explosive forming bag 1, and the detonating cord 8 connected with the detonating bomb 7 is drawn out from the injection hole 3 through the inside of the explosive forming bag 1 .

[0030] In the third step, a load-bearing rope ...

Embodiment 2

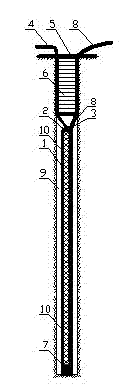

[0033] Embodiment 2: Charge method of contour blast hole:

[0034] A mine slope treatment project, the contour pre-splitting blasting design drilling depth is 15m, the hole diameter is 200mm, the charge length at the bottom of the hole is 10.0m, the length of the blocking section is 2.0m, and the design charge diameter is 60mm. The way is as follows:

[0035] In the first step, an explosive forming bag 1 with a diameter of 60 mm and a length of 10.1 m is selected.

[0036] In the second step, the prepared detonating bomb 7 is put into the explosive forming bag 1, and the detonating cord 8 connected with the detonating bomb 7 is drawn out from the injection hole 3 through the inside of the explosive forming bag 1 .

[0037] In the third step, the load-bearing rope 4 is tied to the handle of the explosive forming bag 1, and the explosive delivery hose is inserted into the bottom of the explosive forming bag 1 from the delivery hole 3 of the forming bag.

[0038] The fourth ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com