Explosion expanded internal anchor head prestressed anchor cable for strengthening weak rock and anchoring method thereof

An internal anchor head and blast expansion technology, which is used in earth-moving drilling, bolt installation, construction, etc., can solve the problem that the prestressed design tonnage cannot be reached, the length of the free tensioning section of the anchor cable is small, and the grouting body is fractured and sheared. and other problems, to achieve the effect of expanding the range of force, improving the effective range, and large anchor cable tension load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further introduced below in conjunction with specific embodiments of the present invention. The concrete realization process of the prestressed anchor cable in the explosive expansion inner anchor head proposed by the present invention is as follows:

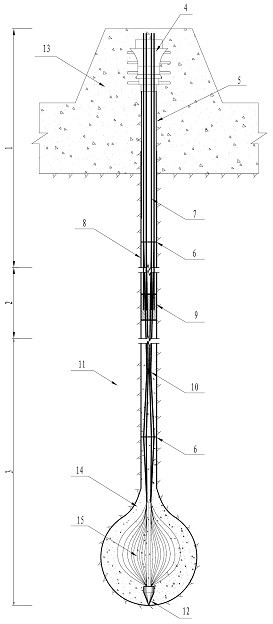

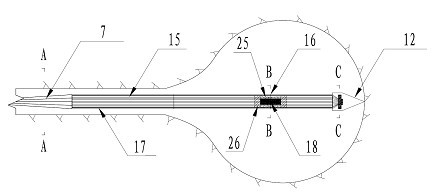

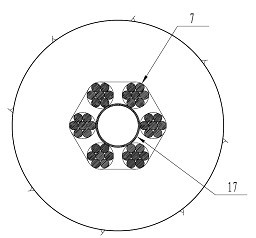

[0047] Such as figure 1 As shown in Fig. 1, the prestressed anchor cable with the inner anchor head of explosive expansion for strengthening the weak rock mass is composed of the free section (1), the grout stop section (2), and the inner anchor section (3) of the anchor cable. Follow the steps below to construct the anchor cable:

[0048] One, such as figure 2 As shown, a rotary drilling rig is used to drill anchor cable holes in the rock mass, with a diameter of 130mm; after the drilling is completed, 100g and 200g spherical emulsion explosives are placed at the bottom of the hole twice for blasting and reaming, and high pressure is used after each reaming The air is used to clear the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com