Millisecond blasting ore-waste separating method of gentle-inclined narrow ore body

A technology of micro-differential detonation and separation method, applied in the field of mining, can solve the problems of not reaching the industrial utilization grade, high dilution rate, and lower ore grade, so as to improve resource utilization rate and recovery rate, facilitate mastery, and reduce waste The effect of stone discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

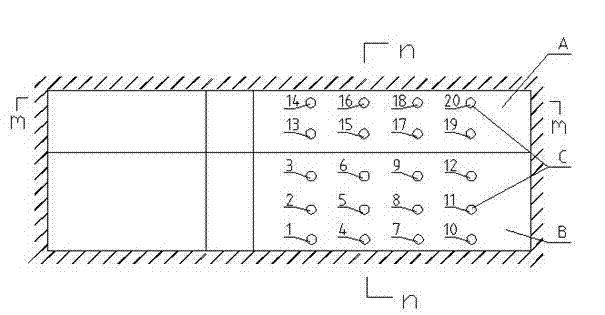

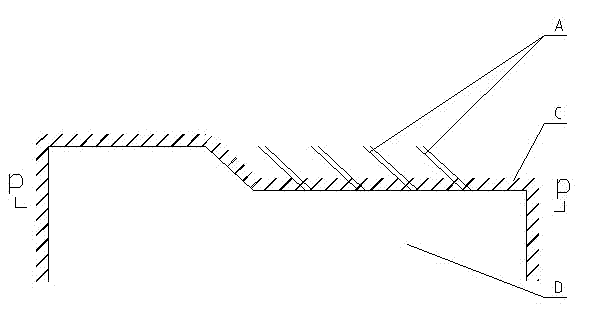

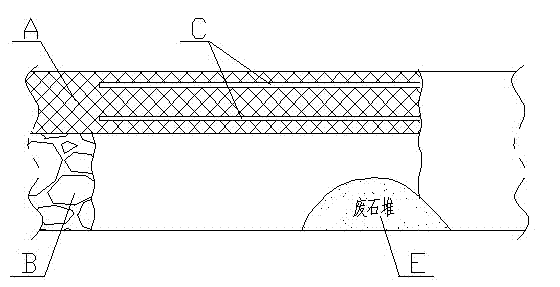

[0020] Example 1 as Figure 1-4 Shown: a method for separation of ore wastes by micro-detonation detonation of a gently inclined thin ore body, including the ore body whose inclination angle is between 0°-30° and the thickness of the ore body is within 1 meter mined by the full-scale mining method or the room-and-pillar mining method Gently inclined thin ore body mining, drilling blast holes in the ore body and waste rock respectively, and blasting after the blast holes are filled with explosives. The process parameters and steps include:

[0021] [1] Drill the ore body blast holes and the waste rock blast holes in the ore body and the waste rock at the same time at the same time, and select the arrangement spacing of the blast holes according to the performance of the ore or rock; the row spacing of the blast holes is 0.6-0.8 meters, The blast hole distance is 0.5-0.7 meters, and the blast hole depth is 1.2-2.0 meters;

[0022] [2] The amount of explosives loaded in waste ro...

Embodiment 2

[0025] Embodiment 2: According to the performance of the ore or rock, the blast hole row distance described in embodiment 1 is preferably 0.65-0.75 meters, the blast hole pitch is preferably 0.55-0.65 meters, and the blast hole depth is preferably 1.5-1.8 meters; The amount of explosives loaded into the ore blastholes is preferably 0.8-0.9kg / hole, and the amount of explosives loaded into the waste rock blastholes is preferably 1.0-1.1kg / hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com