Open-bench blasting method capable of controlling forward stroke of blasting muck pile

A technology of step blasting and pile blasting, which is applied in the blasting field of open-air step blasting to control the blasting pile advance, so as to ensure the safety of mining operations, reduce damage and loss, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

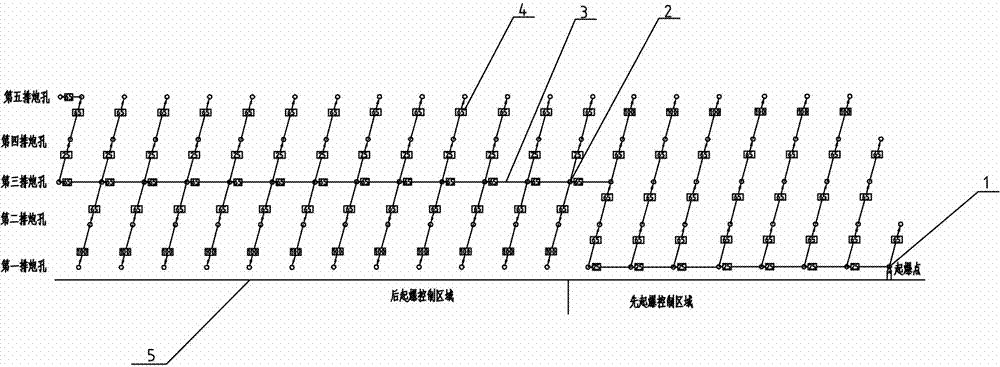

[0040] First carry out the design of deep hole layout and drilling construction. The blasting area is designed with 5 rows, 20 blastholes in each row, triangular holes, hole diameter 250mm, hole spacing 5-8m, row spacing 5-8m, unit step distance 0.5m, hole depth 15m, vertical deep holes, in deep holes The detonating bomb and the detonating detonator are arranged inside, and the time delay of 400ms is adopted in the hole.

[0041] The delayed detonation design of the surface network detonator is carried out according to the following design scheme, the detonator in the blast hole is connected with the surface network detonator and then detonated.

[0042] Delayed detonation design scheme of surface network detonator:

[0043] The first row of blastholes in the first blasting control area is the blasting control row with a 25ms delay between holes, a 65ms delay between rows, and a 100ms delay between rows for the last row of blastholes.

[0044] The middle row of blast holes i...

Embodiment 2

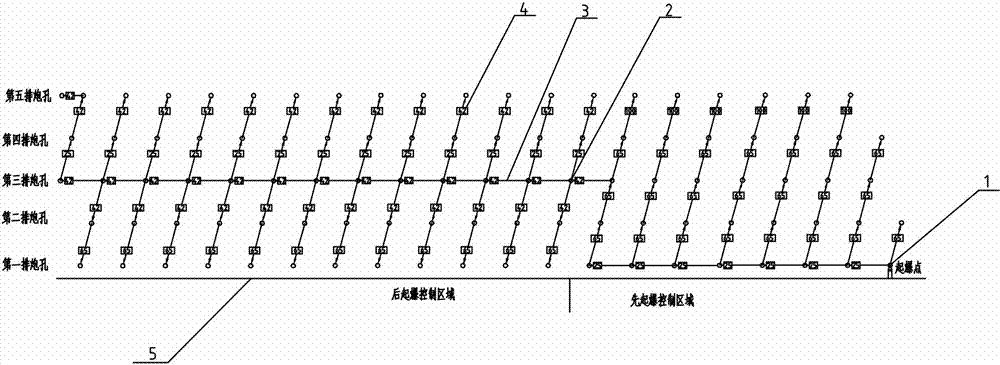

[0046] Such as figure 2 As shown, the deep hole layout design, drilling construction, surface network detonator layout and the delayed detonation design of the surface network detonator in the first detonation area of the present embodiment are the same as in embodiment 1.

[0047] The middle row of blast holes in the rear detonation control area is designed as the blast control row, and the delay time between the holes is 42ms. The delay time between the blast control row and the adjacent fourth row of blast holes is 25ms, and the delay time between the first row of blast holes is 65ms. Delay time, the rest of the rows use a 42ms delay time between rows.

Embodiment 3

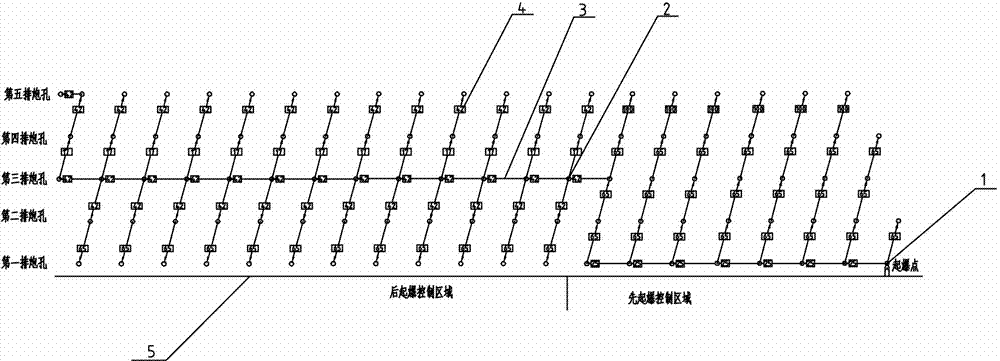

[0049] Such as image 3 As shown, the deep hole layout design, drilling construction, surface network detonator layout and the delayed detonation design of the surface network detonator in the first detonation area of the present embodiment are the same as in embodiment 1.

[0050] The middle row of blast holes in the rear detonation control area is designed as the blast control row, and the delay time between the holes is 42ms. The delay time between the blast control row and the adjacent fourth row of blast holes is 17ms, and the delay time between the first row of blast holes is 65ms. Delay time, the rest of the rows use a 42ms delay time between rows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com