Dynamic seal pressing method and device for improving complex perforation pressing crack effect

A compound perforation and dynamic technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of energy reduction, fracturing efficiency reduction, pressure loss, etc., to reduce gas energy loss and prolong Pressure action time, the effect of improving the pressure waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

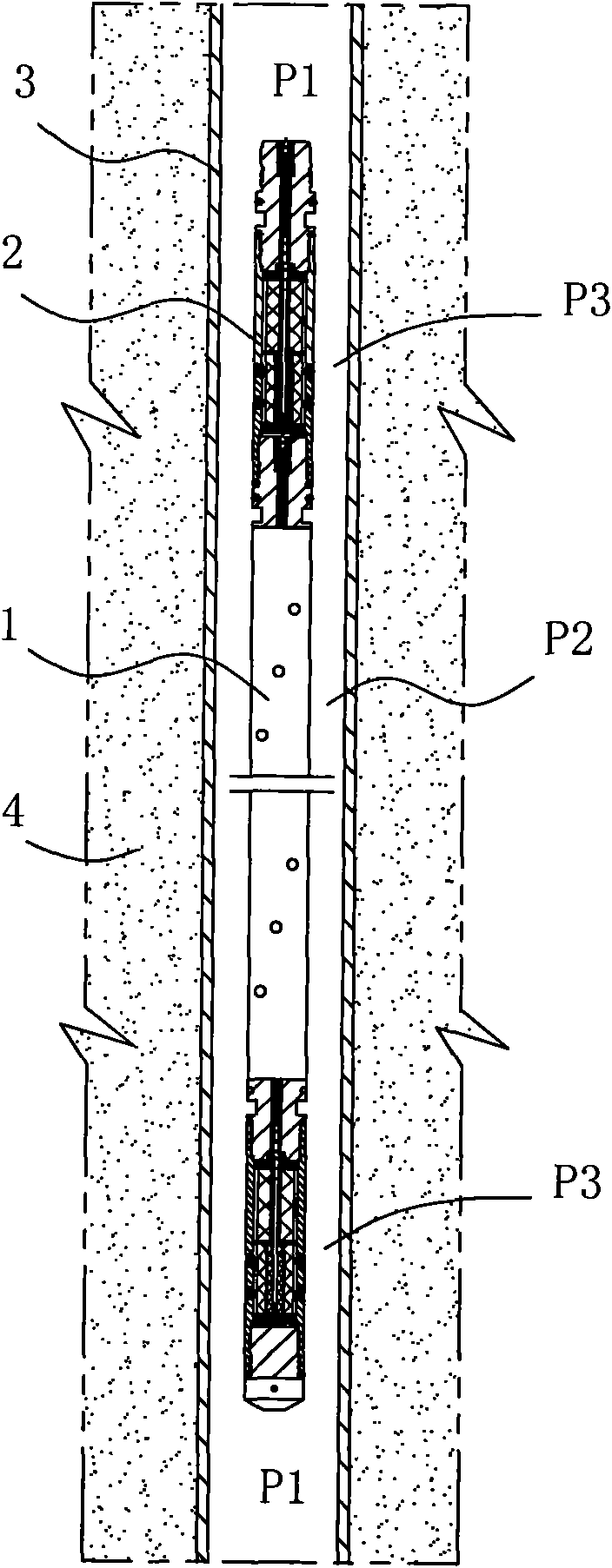

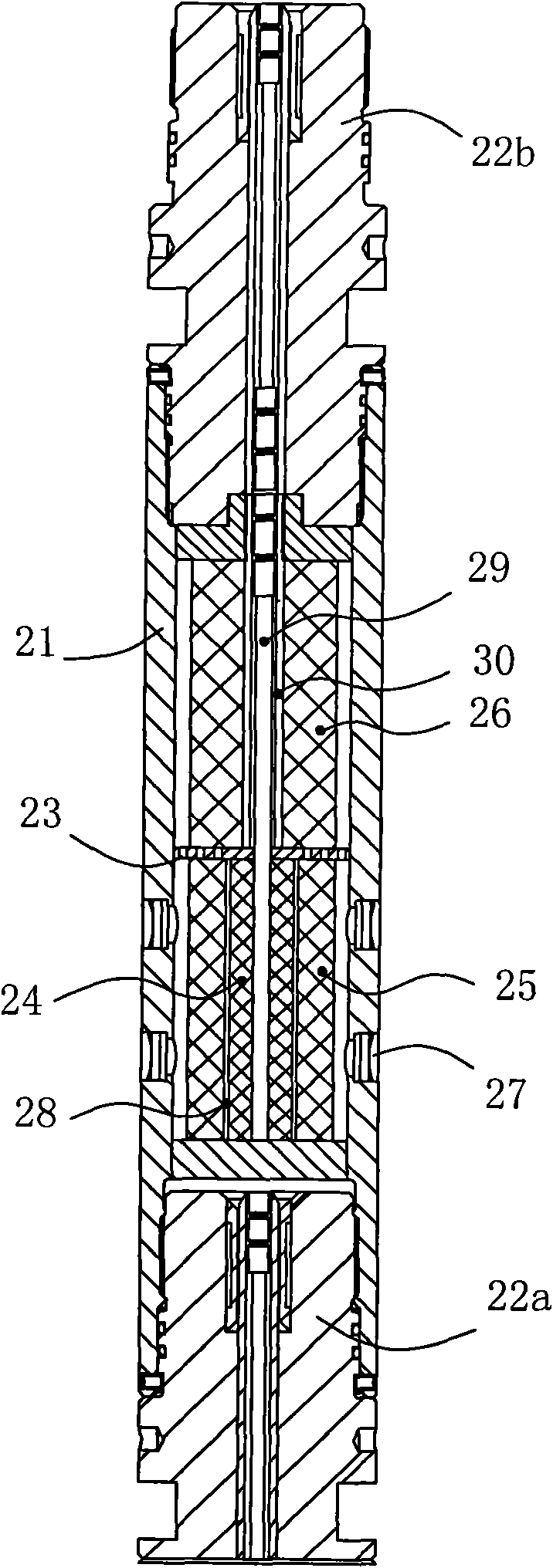

[0022] According to construction requirements, if perforation is to be completed in multiple oil reservoirs at one time, multiple perforating guns need to be connected to form a perforating string, and each perforating gun is aimed at a layer section. The dynamic pressure sealing device of the present invention can be connected to the upper and lower ends of a composite perforating gun in a layer, and can also be connected to the upper and lower ends of a composite perforating gun in a layer with one perforation in multiple layers.

[0023] figure 1 The working principle of the present invention in a layer section is given. The two ends of the perforating gun 1 are respectively connected with a dynamic pressure sealing device 2 , and they are lowered to the set position of the wellbore 3 during compound perforation, and compound perforation is performed on the oil reservoir 4 . The wellbore pressure near the perforating gun 1 before perforation is P1 (the pressure difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com