Testing device for testing deflagration to detonation transition performance of propellant powder

A technology of combustion-to-detonation and test device, which is used in the test of ammunition, ammunition, weapon accessories, etc., and can solve the problems of incompetent launch environment, prone to false triggering, and large result error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Combine below Attached picture The present invention is described in further detail with the embodiment, it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations carried out on the basis of the technical solution of the present invention are all within the protection scope of the present invention.

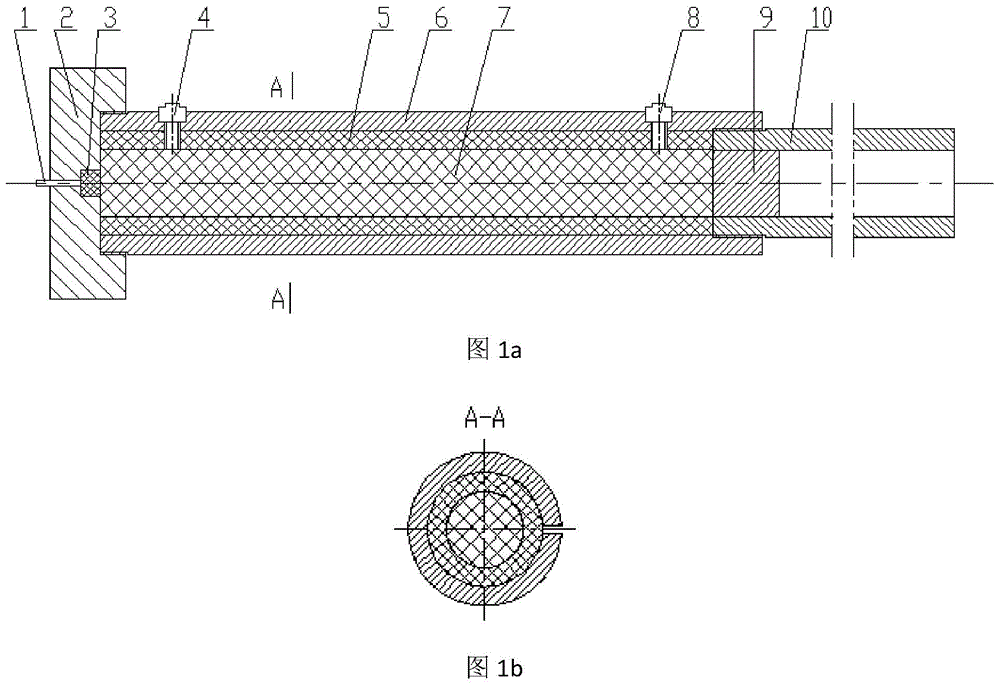

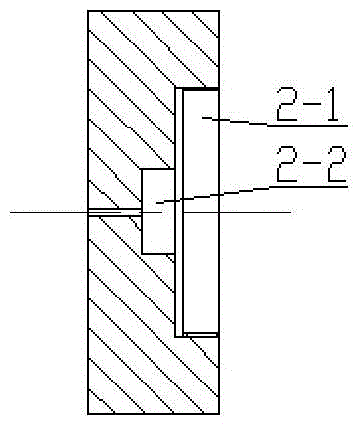

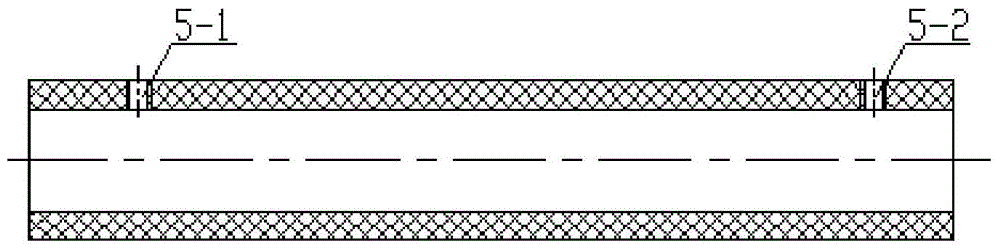

[0017] like figure 1 - Figure 5 As shown, the present embodiment provides a test device for measuring the combustion-to-detonation performance of propellants, including an electric ignition head 1, an end cover 2, an ignition powder 3, a starting point pressure sensor 4, a combustion-to-detonation tube 5, The propellant charge 7 and the terminal pressure sensor 8 are characterized in that they also include a sleeve 6, a simulated bomb 9 and a simulated launch tube 10, wherein the end cover 2 is made of steel with a center step through hole 2-2 in the axial direction. Cylinder, central step th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com